PRODUCTS

PP V30G

Product Struction

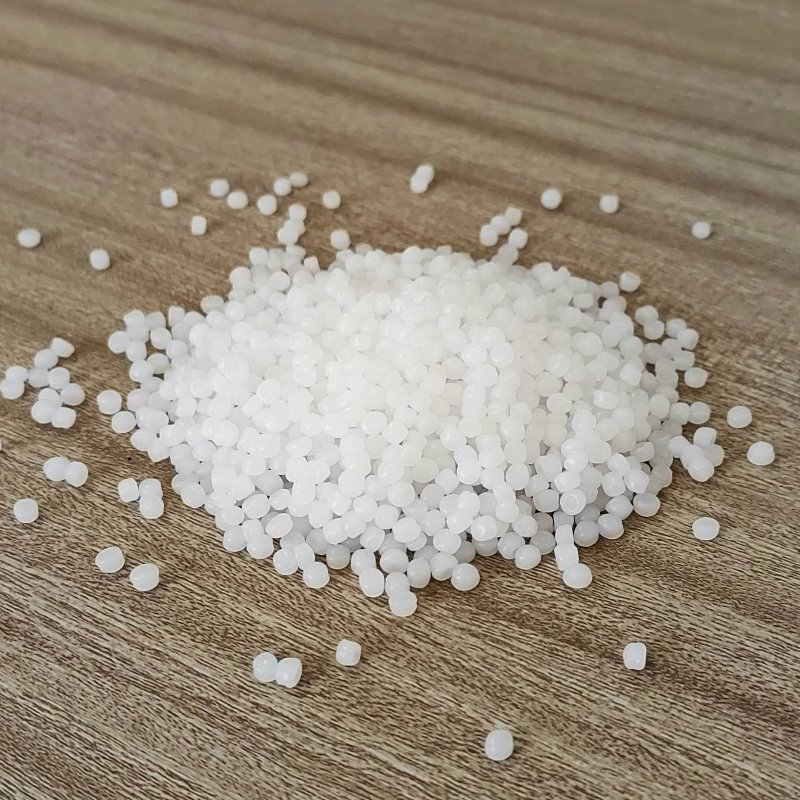

Polypropylene PP V30G Overview

Polypropylene (PP), fully known as Polypropylene, is a long-chain polymer formed by the polymerization of propylene monomers and belongs to thermoplastic polymers. PP has many superior properties, making it widely used in various industries.

PP V30G is a high-performance model of polypropylene. It has excellent resistance to solvents, acids, and alkalis, while also having low water absorption, exhibiting good fatigue resistance and impact resistance. These characteristics make PP an indispensable material in both industry and daily life.

Specifically, PP V30G has a tensile strength of 34 MPa at room temperature (23°C) with an elongation of 12% and a flexural modulus of 1471 MPa. This shows that PP V30G is not only strong and durable but also has a certain degree of elasticity and flexibility. Cantilever beam notch impact test results show its impact resistance is 2 kJ/m², further proving its excellent performance under mechanical stress.

The heat distortion temperature of PP V30G is 87°C, and the Vicat softening temperature reaches 153°C, indicating that it can maintain good shape and performance in high-temperature environments. Additionally, its melt index is 18 g/10min, which means that PP V30G has good fluidity and processing performance, making it suitable for various manufacturing processes.

Due to its outstanding performance, PP V30G is widely used in multiple fields. For example, in household products, PP items such as storage boxes and toys are popular for their lightweight and durability. In the food packaging industry, PP is widely used as food packaging material because of its non-toxic and moisture-resistant properties.

In the medical device field, PP's chemical resistance and sterility make it an ideal material for manufacturing various medical devices. In the automotive industry, PP is widely used in the production of auto parts due to its light weight and durability, contributing to vehicle weight reduction and performance improvement. Additionally, PP can also be seen in electronic equipment and building materials, where its electrical insulation properties and weather resistance provide a reliable material choice for these fields.

| Mechanical behavior | Condition | Standard | Value | Unit |

| Charpy | Notch Impact | ISO 179 | 1.7 | kJ/m² |

| Flexural | Modulus 23°C | ISO 178 | 1139 | MPa |

| Tensile | Strength Yield 23°C | ISO 527 | 32 | MPa |

| Optical performance | Condition | Standard | Value | Unit |

| Yellow | Index | DIN 6167 | -1.4 | YI |

| Physical property | Condition | Standard | Value | Unit |

| Ash | 0.021 | |||

| Melt | Index 230°C 2.16kg | ISO 1133 | 17 | g/10min |

Click here to download TDS for PP V30G

【Related Recommendations】

PP 6331:Low Odor, Food-Grade Polypropylene with Flame Retardancy Learn more>

PP P838C:Rigid Coating-Grade Polypropylene for BOPP Film & Lamination Learn more>

PP PPB-MP03-G(K8003):Impact-Resistant Polypropylene for Fitness Gear Learn more>