PRODUCTS

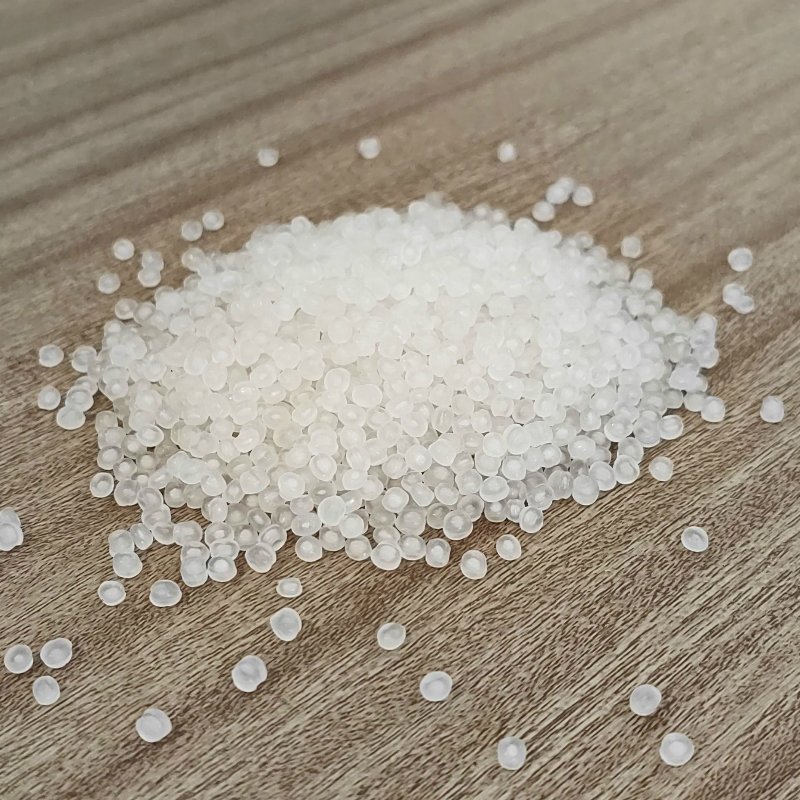

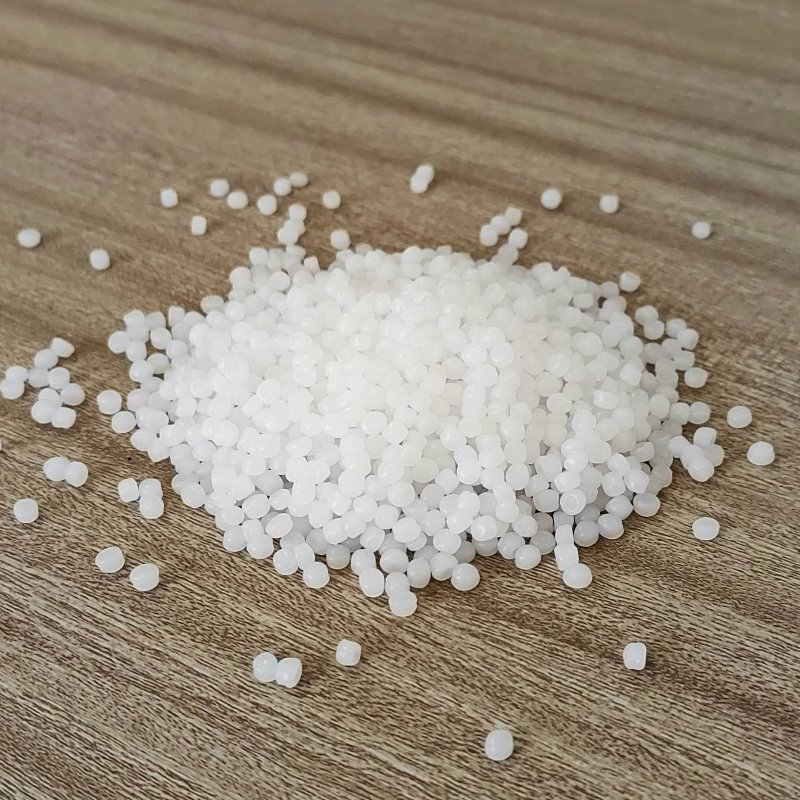

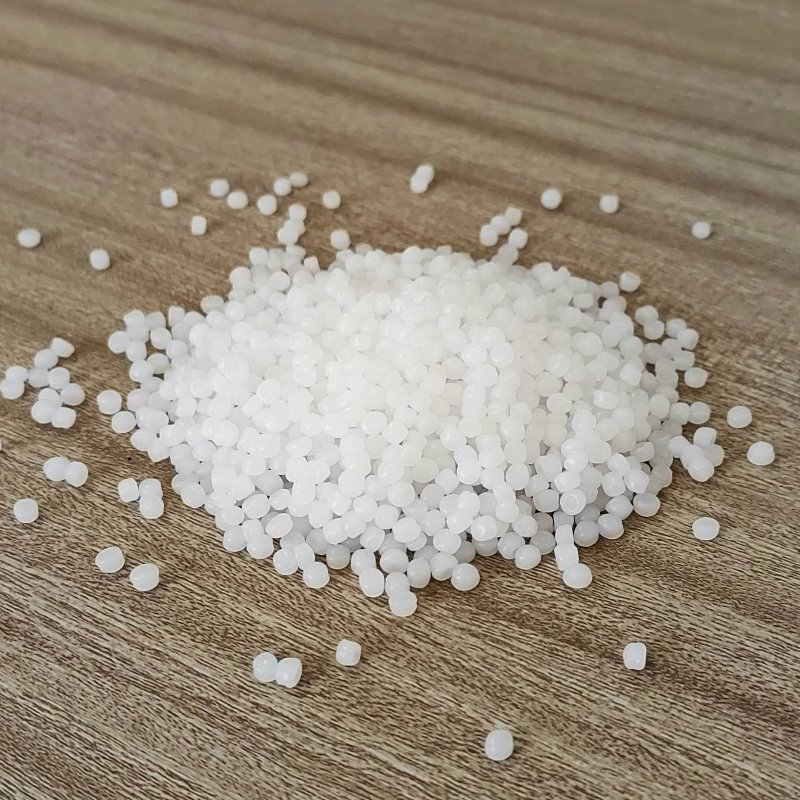

PP HP500P

Product Struction

PP (polypropylene) is a widely used thermoplastic material with excellent heat resistance, corrosion resistance, mechanical strength, and rigidity. As a lightweight material, PP has a density of only 0.90-0.91g/cm³ and offers good plasticity. Additionally, PP has outstanding electrical insulation properties and transparency, along with superior weather resistance and durability. Therefore, PP is extensively used in various fields such as household items, food packaging, medical devices, automotive parts, electronic equipment, and building materials.

Among them, PP HP500P is a high-performance homopolymer material in granular form, suitable for injection molding and composite molding processes. This material not only meets food contact grade standards but also offers dimensional stability, high fluidity, high rigidity, and excellent filling performance. Due to its easy molding and short molding cycle, PP HP500P is widely used in toys, boxes, shields, bottle caps, containers, household items, thin-walled products, masterbatch composite molding, and injection molding applications.

Here are some of the performance indicators of PP HP500P:

| Aging | Condition | Standard | Value | Unit | |||

| Accelerated | Oven Aging in Air 150°C | ASTM D3012 | 360 | hr | |||

| Hardness | Condition | Standard | Value | Unit | |||

| Rockwell | Hardness R(Scale) | ASTM D785 | 103 | ||||

| Mechanical behavior | Condition | Standard | Value | Unit | |||

| Elongation | Yield | ASTM D638 | 12 | % | |||

| Flexural | Modulus | ASTM D790 | 1550 | MPa | |||

| Izod | Notch Impact 23°C | ASTM D256 | 30 | J/m | |||

| Tensile | Strength Yield | ASTM D638 | 33 | MPa | |||

| Physical property | Condition | Standard | Value | Unit | |||

| Density | ASTM D1505 | 0.9 | g/cm³ | ||||

| Melt | Index 230°C 2.16kg | ASTM D1238 | 17 | g/10min | |||

| Thermal | Condition | Standard | Value | Unit | |||

| HDT | 0.45MPa | ASTM D648 | 95 | °C | |||

| Vicat | Softening Temperature 10N | ASTM D1525 | 154 | °C | |||

Due to the high-performance characteristics of PP HP500P, it finds widespread application in various fields. For example, in toy manufacturing, PP HP500P provides sufficient strength and durability. In food packaging, it is not only safe and reliable but also extends the shelf life of products. In the medical device field, the high heat resistance and corrosion resistance of PP HP500P ensure the hygiene and durability of the devices.

Moreover, PP HP500P performs excellently in automotive parts, electronic equipment, and building materials. Its high fluidity and easy molding characteristics make it an ideal choice for thin-walled products and components with complex shapes.

As a high-performance thermoplastic material, PP HP500P is widely used in various industries due to its excellent physical and mechanical properties. Its high fluidity, high rigidity, and ease of molding meet the high standards required by modern manufacturing.

Whether in household items, food packaging, or in medical devices and automotive parts, PP HP500P demonstrates its unique advantages, making it an important material choice across different industries.