PRODUCTS

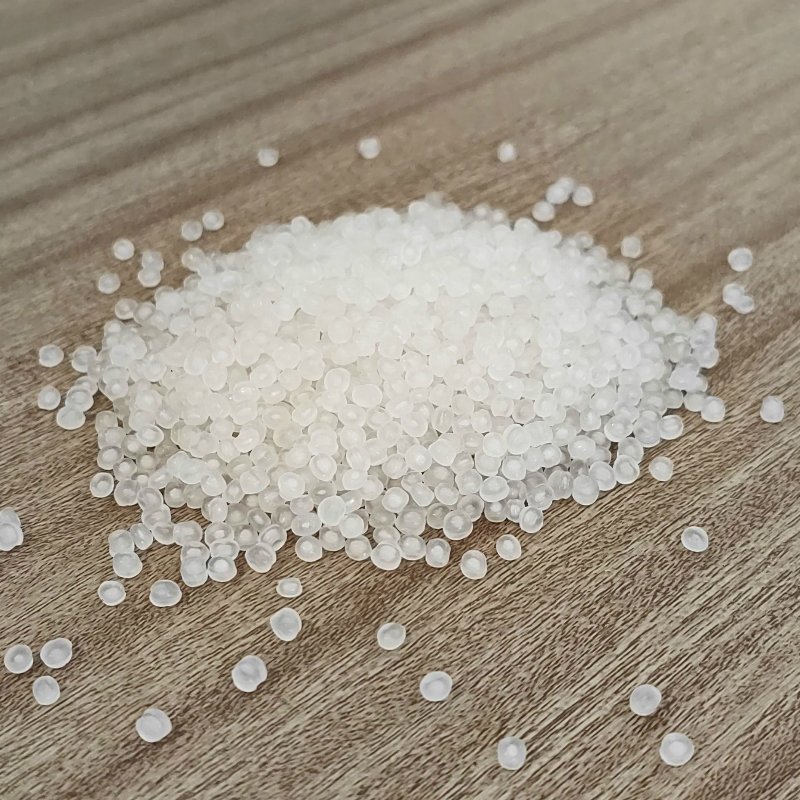

PP Moplen HP500N High rigidity pp plastic raw material

Product Struction

PP HP500N is a high-quality polypropylene (PP) material with a range of outstanding properties and diverse application fields. PP is a thermoplastic resin known for its excellent heat resistance, corrosion resistance, mechanical strength, and rigidity. It also possesses good fatigue resistance and impact resistance, maintaining stable performance under various harsh conditions.

PP has a low density, with a specific gravity of only 0.90-0.91g/cm³, making it lightweight and highly moldable. Additionally, PP boasts good electrical insulation properties and transparency, making it widely used in electronic devices and transparent packaging materials. Its weather resistance and durability also make it an ideal choice for outdoor applications.

Specifically, PP HP500N inherits all the advantages of PP and performs even better in certain aspects. For example, PP HP500N has higher tensile strength and flexural modulus, making it superior in mechanical properties. These characteristics make PP HP500N particularly suitable for applications requiring high strength and rigidity.

In terms of application fields, PP HP500N is widely used in household goods, food packaging, medical devices, automotive parts, electronic devices, and building materials. In these applications, PP HP500N not only provides the necessary mechanical properties but also ensures the durability and reliability of the products. For instance, in automotive parts, PP HP500N can be used to manufacture bumpers, dashboards, and other critical components, offering excellent impact resistance and durability. In food packaging, PP HP500N is an ideal choice due to its excellent transparency and non-toxicity.

| Mechanical behavior | Condition | Standard | Value | Unit | |||

| Charpy Notch Impact | 23°C 1eA | ISO 179 | 4 | kJ/m² | |||

| Tensile Modulus | ISO 527 | 1400 | MPa | ||||

| Tensile Strength | Yield | ISO 527 | 35 | MPa | |||

| Elongation | Yield | ISO 527 | 10 | % | |||

| Elongation | Break | ISO 527 | 50 | % | |||

| Thermal | Condition | Standard | Value | Unit | |||

| HDT | Unannealed 0.45MPa | ISO 75 | 95 | °C | |||

| Vicat Softening Temperature | 50°C/hr 10N | ISO 306 | 153 | °C | |||

| Vicat Softening Temperature | 50°C/hr 50N | ISO 306 | 85 | °C | |||

| Physical property | Condition | Standard | Value | Unit | |||

| Density | ISO 1183 | 0.90 | g/cm³ | ||||

| Melt Index | 230°C 2.16kg | ISO 1133 | 12 | g/10min | |||