PRODUCTS

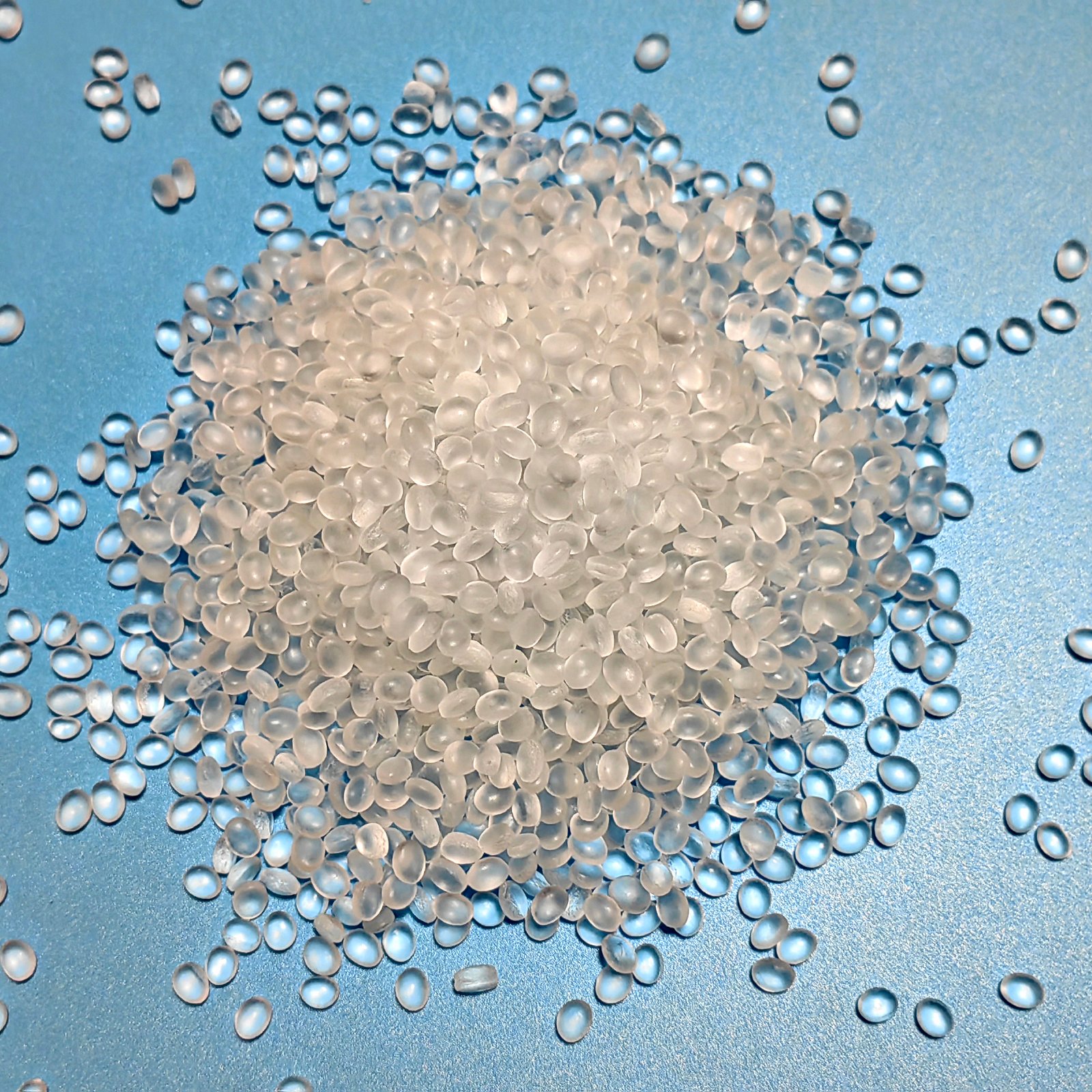

POE Plastic Material Overview | SABIC POE C11075DF with Data Sheet

Product Struction

What is POE Plastic Material

With the rapid development of green manufacturing, lightweight design and flexible functional materials, traditional elastomer materials are gradually being replaced by a new generation of high-performance polyolefin elastomers (POE plastic material). In this wave of transformation, POE C11075DF launched by Saudi Basic Chemicals Company (SABIC) has become the preferred foaming substrate in the fields of automobiles, construction and sports goods with its metallocene catalytic technology, precise polymerization control and low specific gravity characteristics.

01 | POE Plastic Material property highlights: A balanced system of lightness, flexibility and strength

Metallocene catalysis: Controllable performance and uniform molecular distribution

・By adopting an advanced metallocene catalyst system, the precise construction of the ethylene-octene copolymer structure was achieved. The molecular chain segments of the material became more regular, bringing better mechanical balance.

Excellent low-temperature elasticity and thermal stability

・The glass transition temperature is as low as -52°C, maintaining the material's flexibility and resilience in cold environments.

・The melting temperature is 62°C, making it suitable for low-temperature foaming and thermal processing control.

A pioneer in lightweight design

・The specific gravity is only 0.868 g/cm³, which is lighter than traditional elastomers, providing design space for weight reduction of automobiles and lightweighting of sports equipment.

The physical property manifestation that combines hardness and softness

・The tear strength is as high as 39 KN/m, ensuring the crack resistance strength in the foamed structure.

・The Shore hardness A is 71, which can provide structural support while maintaining a soft touch.

02 | Application scenario expansion: from under the hood to the soles of sports shoes

Automotive field: Lightweight cushioning and sealing shock absorption

It is applicable to automotive interior foam parts, soft anti-collision parts for engine compartments, foam layers for floor MATS, etc., and takes into account both deformation buffering and compliance with environmental protection regulations.

In the field of architecture: The combination of energy conservation and vibration isolation

It is widely used as a cushion layer under insulation boards and roof rolls, and for impact-resistant foaming sealing. It has significant advantages in energy absorption and buffering as well as heat isolation.

In the field of sports goods: comfort and protection are given equal importance

It is particularly suitable for fields such as sports shoe soles, yoga MATS, and protective pads that have high requirements for elasticity, lightness, and fatigue resistance.

03 | Processing advantages and process adaptability

High foaming adaptability: It contains foaming agents and is suitable for physical foaming, chemical foaming and other processes.

Friendly molding method: Recommended for foaming extrusion, compression molding, injection molding auxiliary foaming and other processes, especially suitable for continuous sheet foaming production lines.

Excellent formula compatibility: It can be blended with various elastomers such as EVA, LDPE, and TPE to achieve multi-functional performance combinations.

04 | Technical performance overview: structural logic behind the data

| Mechanical behavior | Condition | Standard | Value | Unit | |||

| Flexural Modulus | 1% Secant | ASTM D790 | 13 | MPa | |||

| Tearing Strength | ASTM D624 | 39 | KN/m | ||||

| Thermal | Condition | Standard | Value | Unit | |||

| Melting Temperature | INTERNAL METHOD | 62 | °C | ||||

| Glass Transition Temperature | INTERNAL METHOD | -52.0 | °C | ||||

| Physical property | Condition | Standard | Value | Unit | |||

| Density | ASTM D1505 | 0.868 | g/cm³ | ||||

| Melt Index | 190°C 2.16kg | ASTM D1238 | 1 | g/10min | |||

| Melt Index | 230°C 2.16kg | ASTM D1238 | 2 | g/10min | |||

| Hardness | Condition | Standard | Value | Unit | |||

| Shore Hardness A | 1s | ASTM D2240 | 71 | ||||

| Shore Hardness D | 1s | ASTM D2240 | 21 | ||||

05 | Why choose POE C11075DF Plastic Material?

・By adopting solution polymerization and metallocene copolymerization technology, the performance is more stable and controllable.

・It is suitable for medium foaming and high foaming application scenarios, expanding the elastic window of the finished product.

・Green and environmentally friendly, halogen-free, and adaptable to the market environment requirements of the European Union and the world.

・It has strong expandability and can be used as an important raw material for high-end foaming materials and elastic modification masterbatches.

06 | Obtain samples and technical cooperation suggestions

If you are looking for a POE material that is lightweight, flexible and adaptable to multi-functional processing, POE C11075DF is undoubtedly a high-potential option worthy of close attention.

As a supplier with 24 years of experience in plastic raw material trading and customization, we not only have a wide range of brand and model channels, but also can meet your specific needs:

・Quickly provide free samples and test suggestions to help you accelerate the project verification progress;

・Assist in material modification and new product development to inject more possibilities into innovative products;

・In the face of any technical challenge, we are always glad to be your reliable partner.

Welcome to contact us to obtain complete technical materials and customized recommendation solutions, and enable POE C11075DF to empower new value for your products.

【Related Recommendations】

The Evolution of Plastic Pellets: From Raw Material Procurement to Product Strategy Redefinition Learn more>

POE LC670: Versatile Polyolefin Elastomer for Automotive and Footwear Innovations Learn more>

PVC vs. TPU Material: A Strategic Material Decision That Defines Your Market Edge Learn more>