PRODUCTS

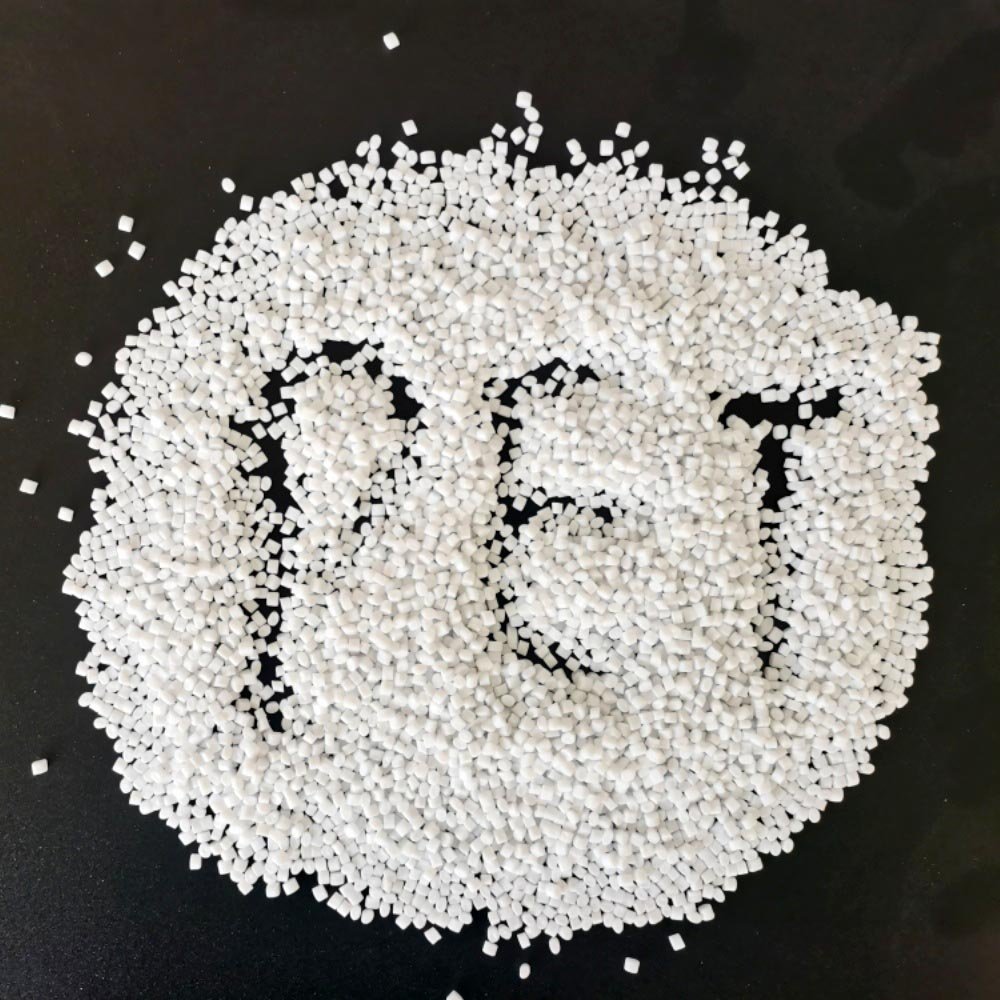

PET Resin Pellets Overview | PET 8050 Advantages & Datasheet

Product Struction

What is PET Resin Pellets

In the field of plastic applications, materials that balance mechanical strength, thermal stability and flame retardancy have always been the focus of high-end manufacturers. PET 8050, a high-performance balanced pet resin pellets developed by Applied Composites, meets high reliability requirements in a wide range of fields, from electrical insulation to industrial structural components.

01 | The "backbone" of Engineering plastics: The Positioning and Advantages of PET 8050

Compared with traditional engineering materials such as glass fiber reinforced PA and PBT, PET 8050 resin pellet has achieved breakthroughs in the following aspects:

Stronger dimensional stability: Low thermal expansion rate, suitable for precision forming parts;

Lower water absorption rate: Superior to PA materials, avoiding performance deterioration caused by moisture absorption;

Stable heat resistance: With a heat distortion temperature of 232°C, it can handle high-temperature working conditions without any pressure.

Self-contained flame retardancy: UL94 V-0 grade can be achieved without additional additives, reducing system cost and formula complexity.

02 | Typical Application Analysis: Understanding the practical value of PET 8050 from the design perspective

Many designers encounter the following challenges in the early stage of material selection:

1) Some structural components are required to be resistant to bending and impact, but flame retardancy must not be sacrificed.

2) Some electronic carrier components are limited by processing temperature, and traditional PC or PBT cannot meet the forming window requirements.

3) It has high requirements for dimensional accuracy and stability, and must not affect assembly or performance due to moisture absorption deformation.

In these scenarios, PET 8050 shows a high degree of adaptability. Take the inductor skeleton as an example. The requirements of this component are:

1) When the wall thickness is less than 1.6mm, the V-0 fire resistance rating still needs to be met.

2) No deformation should occur in the wave soldering or reflow soldering process.

3) The material must not deteriorate when the long-term operating temperature exceeds 120°C.

PET 8050 resin pellet, with its high modulus, low moisture absorption, V-0 flame retardancy and excellent heat resistance, can well meet such challenges.

03 | Performance Comparison with Other Engineering Plastics

| Material Type | Flame Rating | Heat Deflection Temp. | Water Absorption | Tensile Modulus | Molding Difficulty |

|---|---|---|---|---|---|

| Reinforced PA6 | HB or V-2 | 180°C | 1.2% | Medium | Moderate |

| Reinforced PBT | V-0 | 200°C | 0.5% | Medium–High | Slightly High |

| PET 8050 | V-0 | 232°C | 0.2% | High | Moderate |

04 | PET 8050 Resin Pellet Datasheet

| Mechanical behavior | Condition | Standard | Value | Unit | |||

| Compressive Strength | ASTM D695 | 165 | MPa | ||||

| Flexural Strength | 23°C | ASTM D790 | 179 | MPa | |||

| Flexural Modulus | ASTM D790 | 11700 | MPa | ||||

| Izod Un-notch Impact | ASTM D256 | 49.08 | kJ/m² | ||||

| Izod Notch Impact | 23°C | ASTM D256 | 81.73 | kJ/m² | |||

| Tensile Strength | 23°C | ASTM D638 | 96.5 | MPa | |||

| Tensile Modulus | 23°C | ASTM D638 | 13100 | MPa | |||

| Thermal | Condition | Standard | Value | Unit | |||

| HDT | Unannealed 1.8MPa | ASTM D648 | 232 | °C | |||

| Physical property | Condition | Standard | Value | Unit | |||

| Water Absorption | 23°C 24hr | ASTM D570 | 0.2 | % | |||

| Density | ASTM D792 | 1.8 | g/cm³ | ||||

| Hardness | Condition | Standard | Value | Unit | |||

| Baecol Hardness | ASTM D2583 | 55 | |||||

| Flammability | Condition | Standard | Value | Unit | |||

| Flame Rating | 1.5875mm | UL94 | V-0 | ||||

| Flame Rating | 3.175mm | UL94 | V-0 | ||||

| Flame Rating | 6.35mm | UL94 | V-0 | ||||

05 | Sustainability advantage: A new option under the trend of green manufacturing

Nowadays, more and more electronic brand manufacturers take environmental compliance as an important reference standard for purchasing materials.

PET 8050 resin pellet:

Halogen-free flame retardants, in compliance with RoHS/REACH requirements;

There is no irritating odor during the processing, and it is suitable for clean workshops and medical electronic components;

It has good recyclability and helps achieve full life cycle management of products.

06 | Who is suitable for using PET 8050?

This material is particularly recommended for:

Electronic/electrical products with the triple requirements of "flame retardancy + precision + heat resistance";

Industrial parts that are exposed to long-term high-temperature working conditions or humid environments;

Application scenarios where high-cost special engineering plastics need to be replaced to control the budget.

07 | We can provide you with:

PET 8050 Technical Data Sheet and Typical Processing Suggestions

Small-batch sampling service, supporting verification of different batches

Quick response pre-sale selection suggestions and after-sale technical support

Welcome to contact us for samples or one-on-one material selection assistance!

【Related Recommendations】

PET 850H 80: High-Strength Polyethylene Terephthalate for Premium Packaging Learn more>

PET HY1000 by Eastman: Engineered for Flexible, Strong, and Sustainable Packaging Learn more>

PET CR-8816: High-Clarity, Odorless Polyester for Bottles, Food & Cosmetic Packaging Learn more>