PRODUCTS

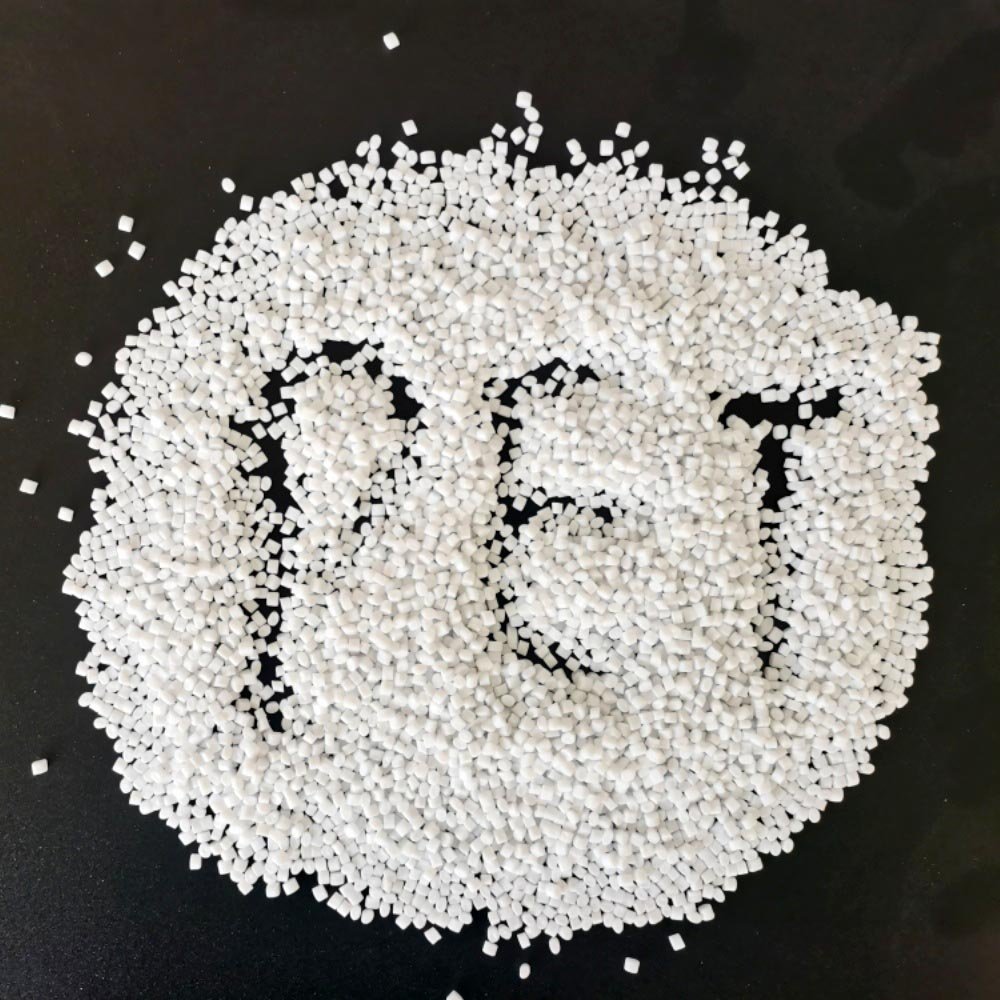

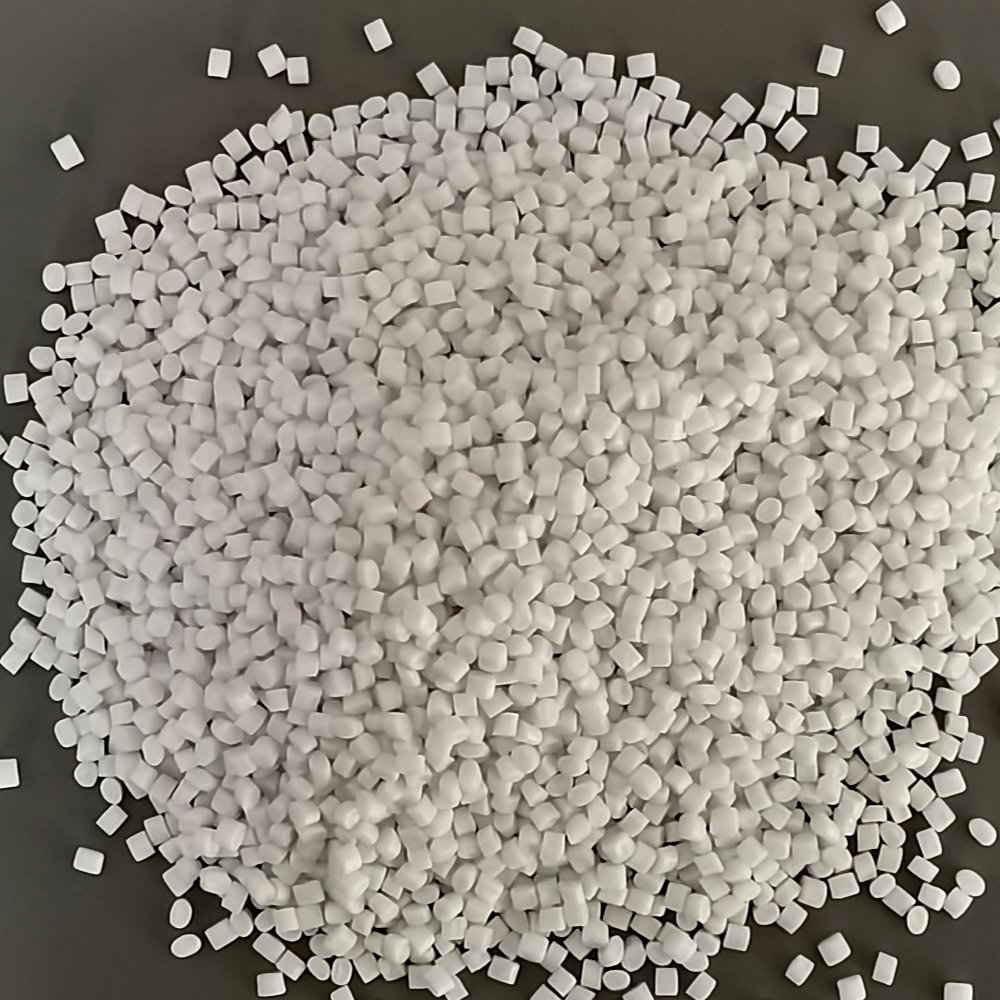

DuPont PET (Polyethylene Terephthalate) 850H 80 Overview

Product Struction

What is PET Polyethylene Terephthalate

As the global packaging industry develops rapidly, the performance of materials must not only meet basic requirements such as strength and transparency, but also take into account sustainability and process adaptability. PET 850H 80 plastic launched by DuPont Teijin, as a highly transparent and high-strength polyethylene terephthalate (PET) material, is not only suitable for food and industrial packaging, but also widely used in high-end electronics, pharmaceutical packaging and other fields due to its excellent processing stability. As an experienced supplier of plastic raw materials, we continue to provide polyethylene terephthalate pet plastic to help our customers stabilise production and improve product quality.

PET 850H 80 Performance Advantages

High Transparency and Optical Stability

PET 850H 80 has a high transmittance of 88.6% and a refractive index of 1.655, demonstrating excellent optical clarity, and is suitable for products with high requirements for packaging appearance, such as high-end food containers and protective packaging for electronic components.

Excellent mechanical properties and strong molding adaptability

This model of PET polyethylene terephthalate has extremely high tensile strength, up to 186 MPa in the flow direction and up to 200 MPa in the vertical direction. It also has good ductility (100% elongation in the flow direction), which effectively improves the impact resistance and deformation resistance of packaging materials.

Precise size control and low shrinkage

PET 850H 80 has a bi-directional shrinkage rate of only 1.25% in the flow direction and 0.3% in the vertical direction, which makes it more suitable for thermoforming, vacuum molding and other processing processes that require strict size requirements, effectively reducing the deformation rate and improving the efficiency of mould reuse.

Excellent barrier performance

Polyethylene terephthalate 850H 80 has a water vapour transmission rate of 27.9 g/m²/day (38°C, 90RH), which can provide better barrier protection for food, medicine and other applications that require moisture-proof preservation, and prolong the shelf life of the products.

High melting point and thermal stability

Pet 850H 80 polyethylene terephthalate has a melting temperature of 254°C, combined with a specific heat capacity of 1.17 J/(kg-°C), which means that the material can be processed and moulded at higher temperatures, and can be adapted to high-speed and high-temperature production lines to reduce the risk of mould sticking.

Environmentally Friendly and In Line with Industry Trends

PET 850H 80 plastic is a fully recyclable polyester material, which is in line with the current direction of green and low-carbon development. Low energy consumption and no odour emission during processing are conducive to the achievement of ESG targets.

In addition, due to its mechanical properties and thermal stability, the material is also gradually being used in the packaging of electronic products and medical devices, where it improves protection and guarantees cleanliness and stability at the same time.

Typical Applications of PET PET 850H 80

Food and beverage packaging (e.g. bottled water containers, food boxes, transparent trays, etc.)

Highly transparent sheet and film extrusion products

Medical packaging and cosmetic shells

Insulation film materials for electronic products

Basic materials for industrial products with high performance requirements

PET Polyethylene Terephthalate Datasheet

| Optical performance | Condition | Standard | Value | Unit | |||

| Refractive Index | ASTM D1003 | 1.655 | |||||

| Transmittance | ASTM D1003 | 88.6 | % | ||||

| Mechanical behavior | Condition | Standard | Value | Unit | |||

| Elongation | Flow | ASTM D882 | 100 | % | |||

| Elongation | xFlow | ASTM D882 | 90 | % | |||

| Tensile Strength | Flow | ASTM D882 | 186 | MPa | |||

| Tensile Strength | xFlow | ASTM D882 | 200 | MPa | |||

| Friction Coefficient | Dynamic | ASTM D1894 | 0.5 | ||||

| Thermal | Condition | Standard | Value | Unit | |||

| Specific Heat | 1.17 | J/(kg·°C) | |||||

| Melting Temperature | 254 | °C | |||||

| Physical property | Condition | Standard | Value | Unit | |||

| Shrinkage | Flow | 1.25 | % | ||||

| Shrinkage | xFlow | 0.3 | % | ||||

| Density | ASTM D792 | 1.4 | g/cm³ | ||||

| Water Vapor Transmission | 38°C 90RH | ASTM F1249 | 27.9 | g/m²/day | |||

Advantages compared with conventional PET Polyethylene Terephthalate

| Performance Index | Conventional PET | PET 850H 80 |

|---|---|---|

| Transparency | Moderate (<85%) | High (88.6%) |

| Tensile Strength | Medium | High Strength (>180 MPa) |

| Shrinkage Control | Relatively Higher | More Stable Precision Molding |

| Application Scope | Basic Packaging | Premium Packaging, Medical, Electronics |

Get in Touch with Us

We have long been focusing on plastic raw materials trade, always stock original genuine DuPont Teijin PET 850H 80 plastic, we support large and small batch purchase, whether it is a sample verification or long-term bulk supply, can flexibly meet your needs.

If you are looking for a PET material that combines transparency, strength and food contact safety, please feel free to contact us for detailed information and real-time quotes, we look forward to providing reliable support for your products.

【Related Recommendations】

PET 7352: High-Strength, High-Clarity Polyester for Food, Cosmetic & Medical Packaging Learn more>

PET HY1000 by Eastman: Engineered for Flexible, Strong, and Sustainable Packaging Learn more>

PET CR-8816: High-Clarity, Odorless Polyester for Bottles, Food & Cosmetic Packaging Learn more>