PRODUCTS

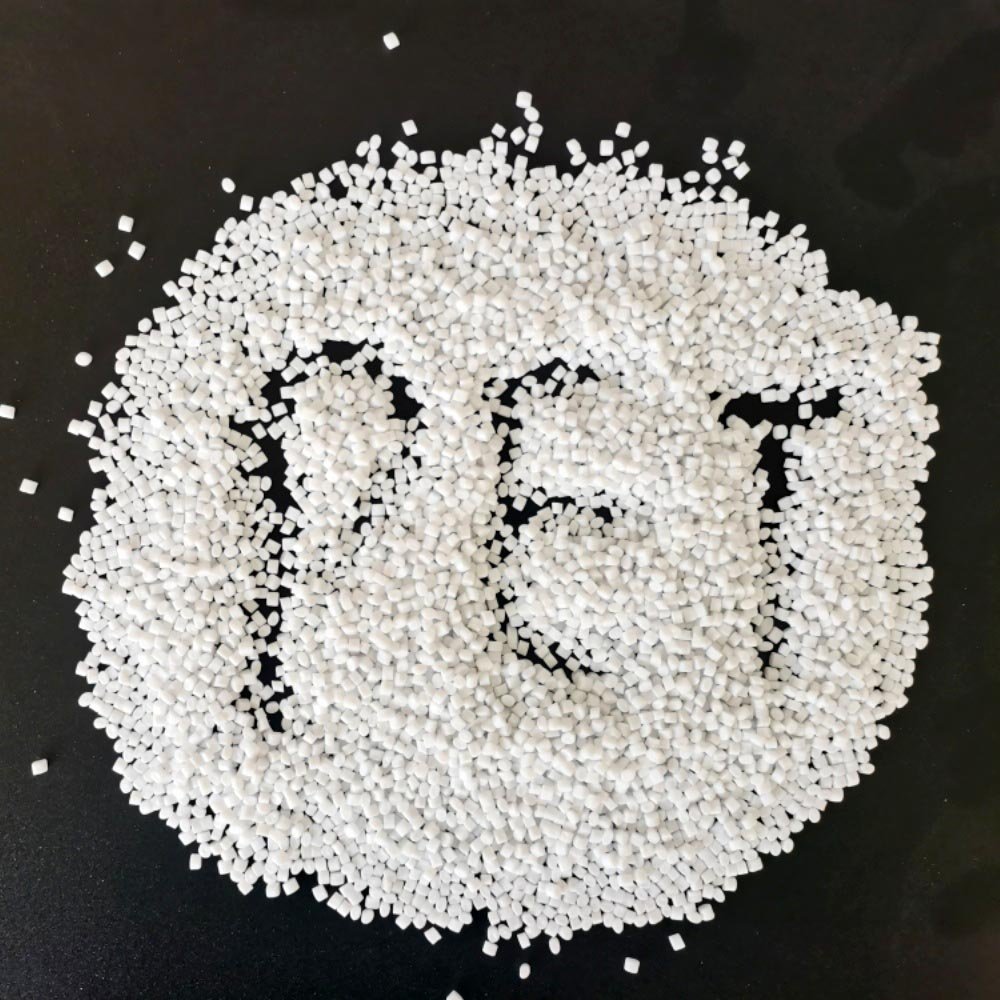

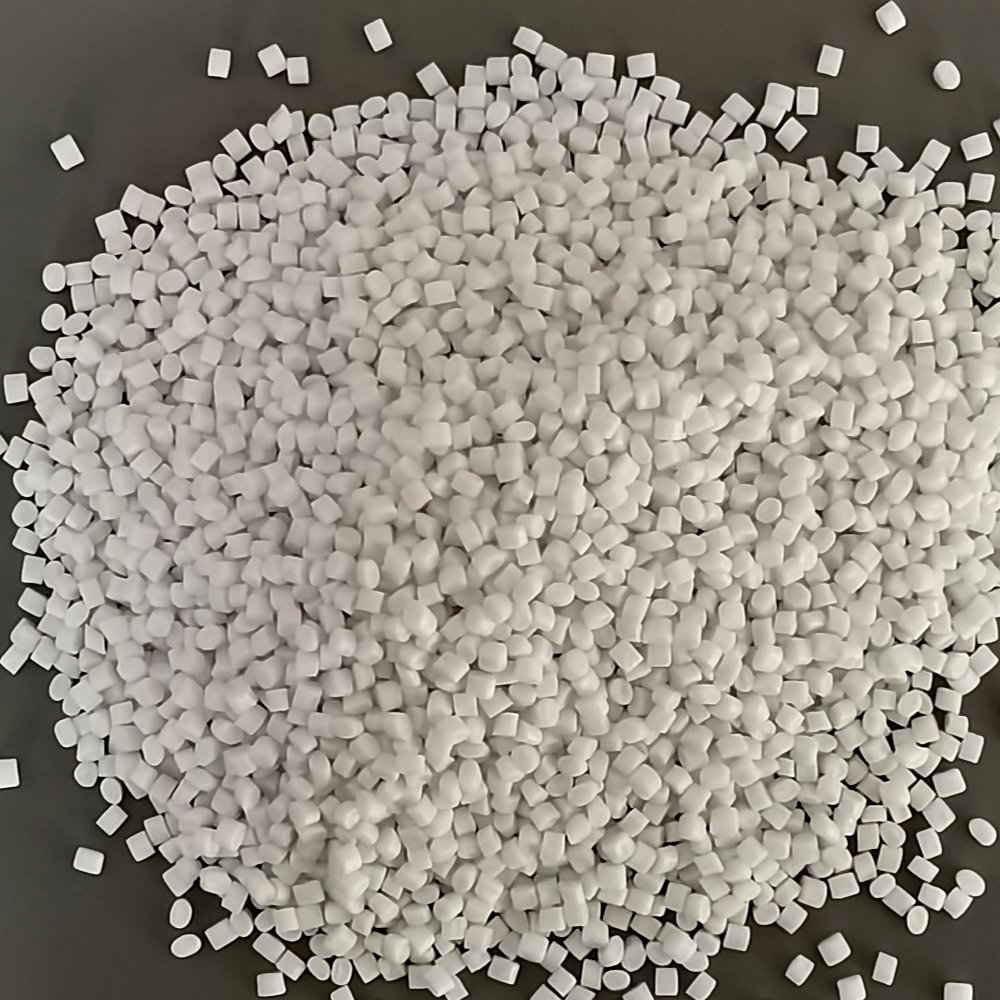

PET 7352 Particles Overview | Advantages and Data Sheet

Product Struction

What is PET Particles ?

In today's era of increasing emphasis on packaging performance and environmental responsibility, Eastman PET plastic particles have become one of the preferred raw materials for many manufacturing companies.This copolymerized polyethylene terephthalate (PET) not only has excellent mechanical strength and thermal stability, but also has high transparency, high gloss, and low acetaldehyde release, which is very suitable for food, cosmetics, medical packaging and functional sheet applications.

Different from traditional packaging materials, PET 7352 can achieve a dual improvement in visual aesthetics and structural performance while maintaining good processability, and is becoming an important material choice for enterprises that pay attention to brand image and user experience.

PET 7352 Particles Advantages

High definition transparency and mirror-like finish: Good optical performance makes the bottle packaging more attractive and enhances the shelf performance of the product, especially suitable for cosmetics and premium beverage markets.

Low acetaldehyde content (3 ppm) : meets safety requirements for drinking water and infant food packaging, helps brands reach consumers who are highly sensitive to health quality.

High molding efficiency: moderate melting temperature (250°C), heat distortion temperature up to 62°C, dimensional stability under high load, suitable for high-speed injection molding and blow molding lines.

Excellent electrical performance: Volume resistance and surface resistance reach 1E16 Ω, suitable for electronic packaging auxiliary components with strict insulation requirements.

Sustainable processing compatibility: This model is compatible with the blending of some recycled PET (rPET), which helps to improve the environmental compliance of downstream products.

PET 7352 Particles Applications

Food and beverage packaging: mineral water bottles, functional beverage bottles, transparent food boxes, pre-prepared food trays

Pharmaceutical and health care product containers: desiccant packaging, medicine blister plates, drop bottles, pressure-resistant preforms

Cosmetic packaging: mask bottles, perfume bottles, lotion bottles, high-end transparent plastic shells

Industrial sheet materials and pallets: vacuum-formed sheets, display boxes, inner lining materials

Electronic insulation packaging: electrical transparent enclosures, auxiliary connection structural components

PET 7352 Particles Datasheet

| Mechanical behavior | Condition | Standard | Value | Unit | |||

| Elongation | ASTM D638 | 4 | % | ||||

| Flexural Strength | Yield 23°C | ASTM D790 | 81 | MPa | |||

| Flexural Modulus | 23°C | ASTM D790 | 2500 | MPa | |||

| Izod Un-notch Impact | ASTM D4812 | NB | kJ/m² | ||||

| Izod Notch Impact | 23°C | ASTM D256 | 5.20 | kJ/m² | |||

| Izod Notch Impact | -30°C | ASTM D256 | 3.67 | kJ/m² | |||

| Tensile Strength | 23°C | ASTM D638 | 26 | MPa | |||

| Tensile Strength | Yield 23°C | ASTM D638 | 57 | MPa | |||

| Thermal | Condition | Standard | Value | Unit | |||

| Avg. Heat of Fusion | ASTM E793 | 63 | J/g | ||||

| Specific Heat | ASTM E1269 | 2100 | J/(kg·°C) | ||||

| HDT | Unannealed 0.45MPa | ASTM D648 | 66 | °C | |||

| HDT | Unannealed 1.8MPa | ASTM D648 | 62 | °C | |||

| Melting Temperature | ASTM D3418 | 250 | °C | ||||

| Vicat Softening Temperature | ASTM D1525 | 79 | °C | ||||

| Physical property | Condition | Standard | Value | Unit | |||

| Acetaldehyde | 3 | ppm | |||||

| Water Absorption | 23°C 24hr | ASTM D570 | 0.1 | % | |||

| Bulk Density | Poured | ASTM D1895 | 0.817 | g/cm³ | |||

| Bulk Density | Vibrated | ASTM D1895 | 0.881 | g/cm³ | |||

| Shrinkage | Flow | ASTM D995 | 0.4 | % | |||

| Density | ASTM D792 | 1.32 | g/cm³ | ||||

| Melt Density | 1.2 | g/cm³ | |||||

| Relative Viscosity | 0.74 | ||||||

| Electrical properties | Condition | Standard | Value | Unit | |||

| Dielectric Constant | 1KHz | ASTM D150 | 3.2 | ||||

| Dielectric Constant | 1MHz | ASTM D150 | 3 | ||||

| Volume Resistivity | ASTM D257 | 1E16 | Ω.cm | ||||

| Dielectric Strength | ASTM D149 | 15.7 | KV/mm | ||||

| Arc Resistance | ASTM D495 | 155 | s | ||||

| Dissipation Factor | 1KHz | ASTM D150 | 0.008 | ||||

| Dissipation Factor | 1MHz | ASTM D150 | 0.02 | ||||

| Surface Resistivity | ASTM D257 | 1E16 | Ω | ||||

| Hardness | Condition | Standard | Value | Unit | |||

| Rockwell Hardness | R(Scale) | ASTM D785 | 110 | ||||

Why Choose PET 7352 Particles

Balance performance and an environmentally friendly future

Facing the global green transformation wave of packaging materials, PET 7352 is not only a "traditional material" that meets physical requirements, but also a new generation of packaging solution that is compatible with performance, brand value and sustainable concepts.

Whether it is for the visual presentation of high-end transparent packaging or for food contact grade applications that meet the regulations of multiple countries, PET 7352 demonstrates flexibility and long-term stability that surpass similar products.

Our Service Advantages

As a professional trading platform for plastic raw materials, we can assist you in flexibly purchasing a variety of global mainstream models including PET 7352, helping you expand the breadth of material selection and the stability of supply guarantee. Relying on our strong upstream channel network and shipping experience, we can respond to your inquiries quickly, assist in providing samples and technical information, and support shipping under various trade modes (FOB/CIF/DDP).

【Related Recommendations】

PET YS-H01: Optimized PET Material for Hot-Filling Applications in Beverage Packaging Learn more>

PET G5801: High-Transparency, Food-Grade Polyester for Packaging, Straps & Sheets Learn more>

Reliable PET Pellet Supplier | Leading Brands & 2025 Forecast Learn more>