PRODUCTS

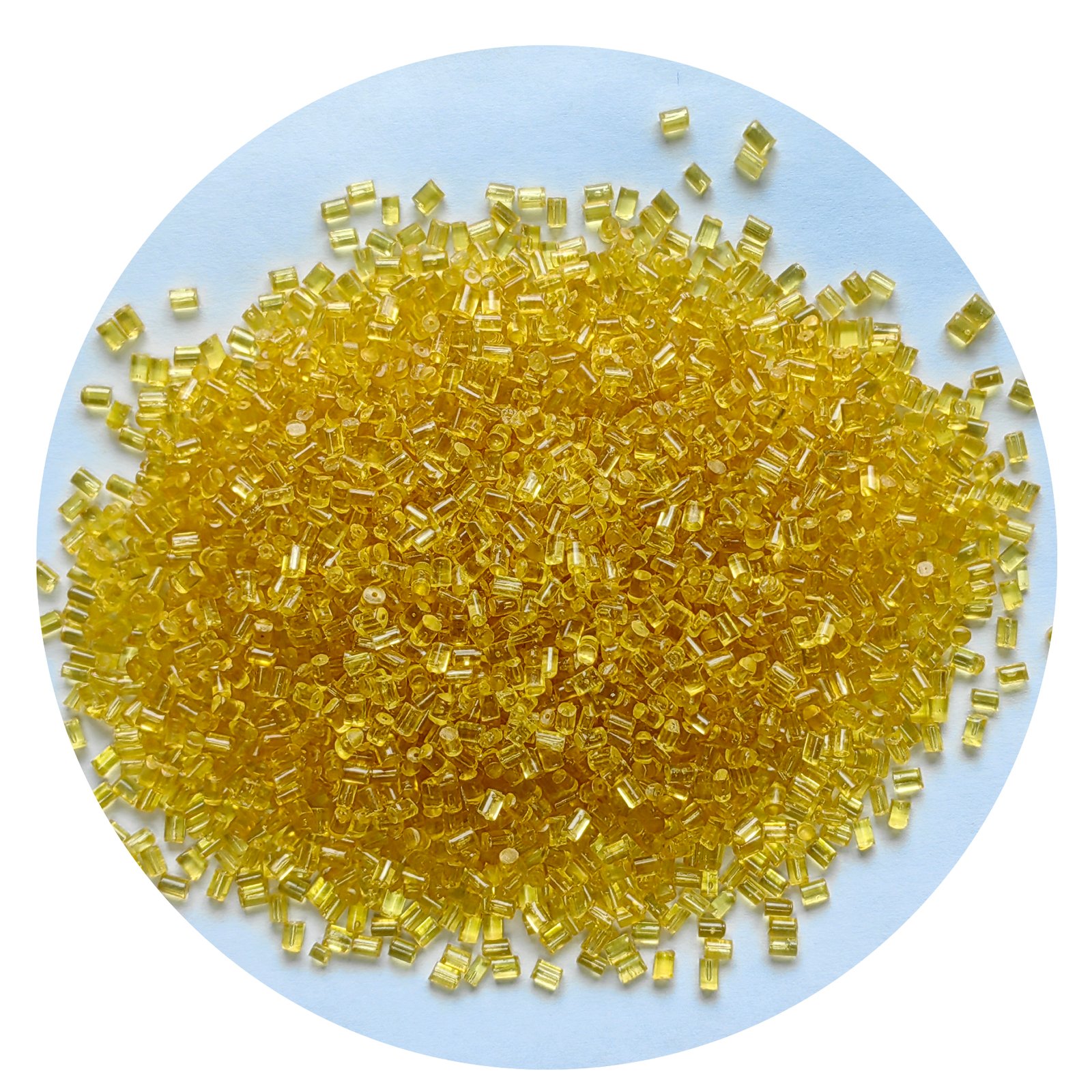

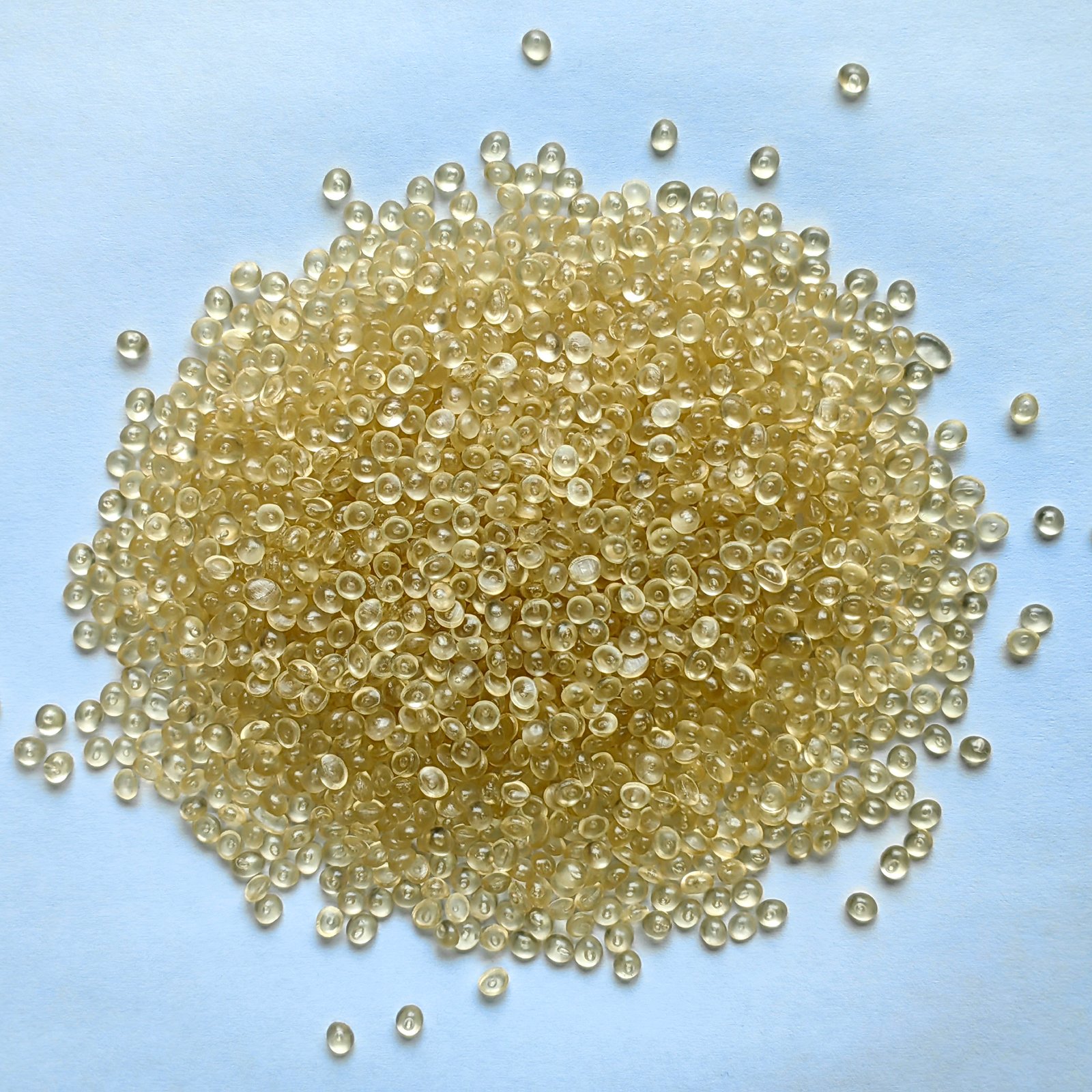

PESU Material BASF 1010 Polyethersulfone for Precision Parts

Product Struction

What is PESU Material

In the field of high-performance engineering plastics, PESU material (polyethersulfone) has long been used in aerospace, medical equipment and electronic connection systems for its excellent thermal stability and electrical properties. However, not all applications require enhanced high-modulus products. For precision parts that need to focus on lightweight, complex structural molding and electrical safety, the emergence of PESU 1010 just fills this gap.

01|What is PESU 1010 material?

PESU 1010 is a non-reinforced, flame-retardant, high-flow polyethersulfone material launched by BASF. The original intention of the design is not to pursue extreme strength, but to provide a better solution for engineering applications that have multiple requirements for molding accuracy, electrical insulation and thermal stability. Without adding glass fiber, it achieves:

Excellent dimensional stability: low thermal expansion coefficient, dimensional change rate close to zero;

Good heat resistance: heat deformation temperature up to 203°C;

Excellent electrical safety: UL94 V-0 (3.0mm), CTI 125V, RTI up to 190°C;

High processing efficiency: melt index up to 150 cm³/10min, especially suitable for thin-wall precision injection molding.

| UL | Condition | Standard | Value | Unit | |||

| CTI | IEC 60112 | 4 | PLC | ||||

| HAI | All Color 1.5mm | UL 746A | 2 | PLC | |||

| HAI | All Color 3.0mm | UL 746A | 1 | PLC | |||

| HVTR | UL 746A | 2 | PLC | ||||

| HWI | All Color 1.5mm | UL 746A | 3 | PLC | |||

| HWI | All Color 3.0mm | UL 746A | 2 | PLC | |||

| RTI | Elec All Color 1.5mm | UL 746B | 180 | °C | |||

| RTI | Str All Color 3.0mm | UL 746B | 190 | °C | |||

| Volume Resistivity | ASTM D257 | 1E16 | Ω.cm | ||||

| Dimensional Stability | UL746 | 0.0 | % | ||||

| Dielectric Strength | ASTM D149 | 28 | KV/mm | ||||

| Arc Resistance | ASTM D495 | 6 | PLC | ||||

| Flame Rating | All Color 1.5mm | UL94 | V-1 | ||||

| Flame Rating | All Color 3.0mm | UL94 | V-0 | ||||

| Mechanical behavior | Condition | Standard | Value | Unit | |||

| Elongation | Yield 23°C | ISO 527 | 6.8 | % | |||

| Izod Notch Impact | 23°C | ISO 180 | 6.5 | kJ/m² | |||

| Izod Notch Impact | -30°C | ISO 180 | 7.0 | kJ/m² | |||

| Tensile Strength | Yield 23°C | ISO 527 | 85.0 | MPa | |||

| Tensile Modulus | 23°C | ISO 527 | 2650 | MPa | |||

| Charpy Un-notch Impact | 23°C | ISO 179 | NB | kJ/m² | |||

| Charpy Un-notch Impact | -30°C | ISO 179 | NB | kJ/m² | |||

| Charpy Notch Impact | 23°C | ISO 179 | 6.5 | kJ/m² | |||

| Charpy Notch Impact | -30°C | ISO 179 | 7.0 | kJ/m² | |||

| Thermal | Condition | Standard | Value | Unit | |||

| HDT | Unannealed 1.8MPa | ISO 75 | 203 | °C | |||

| CLE | Flow | 5.2E-5 | cm/cm/°C | ||||

| Physical property | Condition | Standard | Value | Unit | |||

| Water Absorption | 23°C Saturation | ISO 62 | 2.2 | % | |||

| Water Absorption | 23°C 50RH Balance | ISO 62 | 0.80 | % | |||

| Shrinkage | Flow | ISO 294 | 0.79 | % | |||

| Shrinkage | xFlow | ISO 294 | 0.82 | % | |||

| Density | ISO 1183 | 1.37 | g/cm³ | ||||

| Melt Index | 360°C 10kg | ISO 1133 | 150 | cm³/10min | |||

| Electrical properties | Condition | Standard | Value | Unit | |||

| CTI | IEC 60112 | 125 | V | ||||

| Dielectric Constant | 1MHz | IEC 60250 | 3.80 | ||||

| Dielectric Constant | 100Hz | IEC 60250 | 3.90 | ||||

| Volume Resistivity | IEC 60093 | 1E15 | Ω.cm | ||||

| Dielectric Strength | IEC 60243 | 37 | KV/mm | ||||

| Dissipation Factor | 1MHz | IEC 60250 | 0.014 | ||||

| Dissipation Factor | 100Hz | IEC 60250 | 0.0017 | ||||

| Surface Resistivity | IEC 60093 | 1E15 | Ω | ||||

| Hardness | Condition | Standard | Value | Unit | |||

| Ball Indentation Hardness | ISO 2039 | 154 | MPa | ||||

| Flammability | Condition | Standard | Value | Unit | |||

| Flame Rating | NC Black 1.5mm | UL94 | V-1 | ||||

| Flame Rating | NC BK 3.0mm | UL94 | V-0 | ||||

02|Which engineering problems are suitable for this type of PESU material?

Different from GF reinforced materials that tend to support structures, PESU 1010 is more like a "systematic functional material", and its value lies in improving the precision, safety and production efficiency of equipment.

✅ Injection molding problems of micro electronic housings

Complex structure, thin wall, precise positioning, and extremely high requirements for fluidity, PESU 1010 can significantly reduce the risk of filling dead corners and deformation with its low viscosity and high dimensional stability.

✅ Flame retardant and heat resistant challenges for vehicle connectors

The connector housing must simultaneously meet V-0 flame retardancy, long-term high temperature resistance, and stable electrical insulation. PESU 1010 meets the standards in the 180°C electrical/impact/structural multi-dimensional RTI test and has long-term load capacity.

✅ Insulation protection requirements for electrical control modules

The module housing that works in high voltage and small space requires materials with high resistivity and dielectric strength. The volume resistivity of PESU 1010 is >10¹⁵ Ω·cm, and the insulation strength is as high as 37 kV/mm.

03 | Why choose PESU 1010?

・It does not contain glass fiber and is more suitable for appearance parts and small precision parts;

・It has fast injection molding speed, small warping, and stable processing;

・It can meet the certification requirements of high-demand scenarios such as electrical, electronic, and new energy;

・As a pure PESU material, it can provide more consistent formula customization in the future.

04|How is it different from common reinforced PESU materials?

| Material Grade | Reinforced | Flowability | Flame Rating | Dimensional Precision | Typical Applications |

| PESU 1010 | No | ★★★★★ | V-0 / V-1 | Very High | Precision electronics, complex injection parts |

| E0510 G9 | GF45 | ★★ | Not specified | High | Structural supports, automotive components |

| 2010 G4 MR | GF20 | ★★★ | Flame retardant | Medium to High | Hot water systems, electrical connectors |

| 2010 MR HP | Unfilled | ★★★★ | Non-flame retardant | High | Transparent medical devices, lab equipment |

Summary: When structural parts no longer pursue "harder" but care more about "thinner, more accurate, faster, and safer", the design advantages of PESU 1010 are revealed.

05|What can we provide for you?

As a supplier of engineering plastic materials, we not only provide PESU 1010 spot resources, but also help customers recommend the most suitable models according to different application environments, such as:

| Manufacturer | Product Name | Grade | Density | Melt Flow Rate | Tensile Modulus | Tensile Strength | Elongation at Break |

| BASF | PESU | 2010 SW Q31 10088 | 1.37 g/cm³ | 70 cm³/10min | 2650 MPa | 85 MPa | 6.9% |

| BASF | PESU | 2010 G6 SW 15038 | 1.6 g/cm³ | 25 cm³/10min | 9800 MPa | 150 MPa | 2.3% |

| BASF | PESU | 2010 | 1.37 g/cm³ | 70 cm³/10min | 2650 MPa | 85.0 MPa | 6.9% |

| BASF | PESU | 1010 NAT | 1.37 g/cm³ | 150 cm³/10min | 2650 MPa | 85 MPa | 6.8% |

📩 Welcome to contact us for samples, processing suggestions and data packages to help you complete material selection and product iteration more efficiently.

【Related Recommendations】

PESU E0510 G9 SW 10112: Reinforced Polyethersulfone for Demanding Applications Learn more>

PC ABS Applications Strategy Guide: Industry Trends and Supply Chain Responses Learn more>

PC+ABS TN-7200B: High Rigidity pc abs resin for Large-Scale and Thin-Wall Applications Learn more>