PRODUCTS

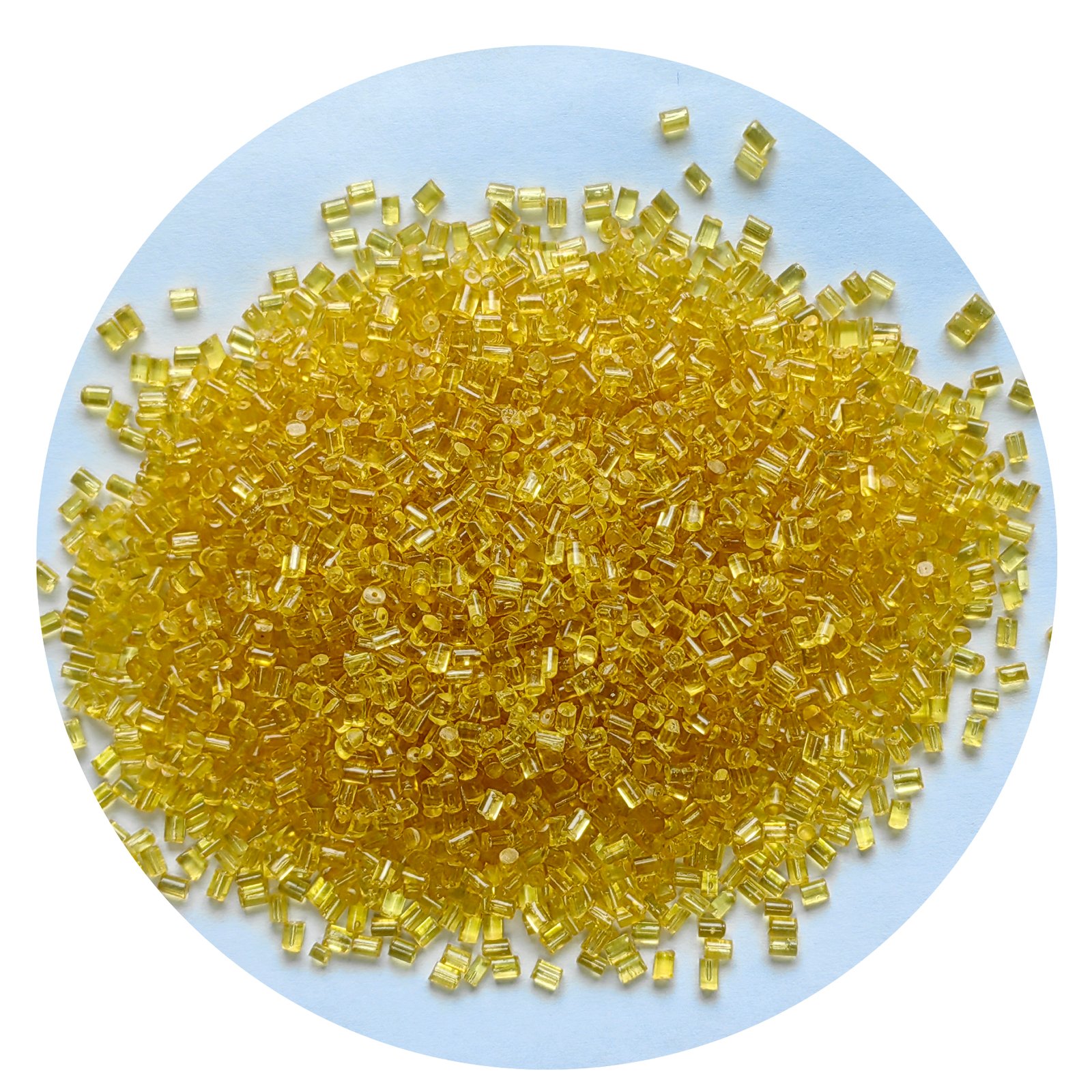

PESU 3010 MR Guide | High Toughness Polyethersulfone Material

Product Struction

What is Polyethersulfone Material

Under extreme working conditions of high temperature, high pressure and high corrosion, whether the material can stand the test of time is more crucial than the parameters. PESU 3010 MR, as a high-viscosity polyethersulfone launched by BASF, not only possesses core advantages such as stress crack resistance, high toughness, and thermal stability, but is also highly suitable for application scenarios with extremely high reliability requirements, including medical, electrical, and industrial fields.

We will guide you to quickly understand the technical value of this polyethersulfone material and tell you why choosing an experienced material trader is far more efficient and worry-free than directly contacting a brand.

01 | Material Introduction: Non-enhanced high-viscosity PESU, breaking the boundaries of traditional formulations

PESU 3010 MR Is a non-reinforced high-viscosity polyethersulfone material with a flame retardant grade of UL94 V-0, and it has the following core properties:

・Non-reinforced design: No addition of glass fiber, yet achieving high toughness and good dimensional stability;

・High stress crack resistance: Effectively resizes the propagation of microcracks caused by stress concentration during long-term use.

・Excellent chemical stability: It has outstanding resistance to acids, alkalis, organic solvents, etc.

・Dual processing method compatibility: Suitable for both injection molding and extrusion processes simultaneously.

This material structure design concept offers a new solution for manufacturers who pursue high toughness and chemical resistance applications without reinforcement.

02 Thermal, mechanical and electrical performance, suitable for multi-industry demanding applications.

In the actual performance test, PESU 3010 MR Demonstrated an all-round excellent performance:

The mechanical properties are balanced, with both toughness and rigidity coexisting

・The tensile modulus is 2650 MPa, which is sufficient to meet the rigidity requirements of most structural components.

・The tensile strength is 85 MPa, ensuring the structural integrity of the product during use.

・The notched impact strength (from -30°C to 23°C) is 8.0 kJ/m², demonstrating its excellent low-temperature toughness.

・The notch-free impact value of the NB grade simply supported beam indicates that the material has an extremely high fracture energy and almost no brittle cracking occurs.

It has strong thermal stability and excellent high-temperature resistance

・The heat distortion temperature (HDT) reaches 207°C, maintaining structural stability in high-temperature environments.

・The coefficient of linear expansion is only 5.2E-5 cm/cm/°C, which is significantly better than most engineering plastics and has strong dimensional stability.

Outstanding electrical insulation performance

・The volume resistance and surface resistance are both in the 10¹⁵ Ω grade, suitable for high insulation requirements.

・The insulation strength is as high as 34 kV/mm, making it safe and reliable in high-voltage environments.

・With a stable dielectric constant (3.80-3.90), it can be widely used in the packaging or isolation of electronic components.

Polyethersulfone material 3010 MR datasheet

| Mechanical behavior | Condition | Standard | Value | Unit | |||

| Elongation | Yield 23°C | ISO 527 | 6.9 | % | |||

| Izod Notch Impact | 23°C | ISO 180 | 8.0 | kJ/m² | |||

| Izod Notch Impact | -30°C | ISO 180 | 8.0 | kJ/m² | |||

| Tensile Strength | Yield 23°C | ISO 527 | 85.0 | MPa | |||

| Tensile Modulus | 23°C | ISO 527 | 2650 | MPa | |||

| Charpy Un-notch Impact | 23°C | ISO 179 | NB | ||||

| Charpy Un-notch Impact | -30°C | ISO 179 | NB | ||||

| Charpy Notch Impact | 23°C | ISO 179 | 8.0 | kJ/m² | |||

| Charpy Notch Impact | -30°C | ISO 179 | 8.0 | kJ/m² | |||

| Thermal | Condition | Standard | Value | Unit | |||

| HDT | Unannealed 1.8MPa | ISO 75 | 207 | °C | |||

| CLE | Flow | 5.2E-5 | cm/cm/°C | ||||

| Physical property | Condition | Standard | Value | Unit | |||

| Water Absorption | 23°C Saturation | ISO 62 | 2.2 | % | |||

| Water Absorption | 23°C 50RH Balance | ISO 62 | 0.80 | % | |||

| Shrinkage | Flow | ISO 294 | 0.85 | % | |||

| Shrinkage | xFlow | ISO 294 | 0.9 | % | |||

| Density | ISO 1183 | 1.37 | g/cm³ | ||||

| Melt Index | 360°C 10kg | ISO 1133 | 35 | cm³/10min | |||

| Electrical properties | Condition | Standard | Value | Unit | |||

| CTI | IEC 60112 | 100 | V | ||||

| Dielectric Constant | 1MHz | IEC 60250 | 3.80 | ||||

| Dielectric Constant | 100Hz | IEC 60250 | 3.90 | ||||

| Volume Resistivity | IEC 60093 | 1E15 | Ω.cm | ||||

| Dielectric Strength | IEC 60243 | 34 | KV/mm | ||||

| Dissipation Factor | 1MHz | IEC 60250 | 0.014 | ||||

| Dissipation Factor | 100Hz | IEC 60250 | 0.0017 | ||||

| Surface Resistivity | IEC 60093 | 1E15 | Ω | ||||

| Flammability | Condition | Standard | Value | Unit | |||

| Flame Rating | All Color 1.5mm | UL94 | V-0 | ||||

| Flame Rating | All Color 3.0mm | UL94 | V-0 | ||||

This set of data reveals that PESU 3010 MR Has high cross-industry adaptability and can meet the performance requirements ranging from electronic and electrical products, medical devices to high-end industrial components.

03 | Application Trend Insights: From Medical Devices to Lightweight Components for Rail Transit

Medical devices

・Syringes and dialysis components that can be used for high-pressure steam sterilization;

・The material is BPA-free and meets the non-toxic requirements for medical devices.

・It has excellent tolerance to cleaning agents and disinfectants.

Electrical and electronic components

・Relay housings, insulating terminals, high-frequency insulating films, etc. used in high-temperature environments;

・Good dimensional stability is suitable for high-precision mating parts.

Industrial filter membrane/module packaging

・The high viscosity property is suitable for membrane shell extrusion, enhancing the overall strength.

・Resistance to organic solvents extends service life.

Rail transit/aviation components

・It meets the requirements of flame retardant V-0 and is lightweight.

・Replace some metals or high-end thermosetting materials to promote lightweight and modular design.

04 | Choices under the Trend of Sustainable Manufacturing: The Environmental Protection and Reuse Potential of PESU

Compared with traditional materials such as PVC and epoxy resin, PESU has greater development potential in terms of environmental friendliness

・The long-life design reduces replacement frequency and waste.

・Halogen-free flame retardant systems are more in line with the EU RoHS and REACH requirements.

・It can be mechanically recycled and reused in non-critical structural components, demonstrating high value in the industrial closed-loop circulation system.

Choosing PESU 3010 MR Is not only about optimizing material performance, but also about paving the way for sustainable manufacturing.

05 | Conclusion: Why choose PESU 3010 MR, but choose us?

As a professional trader with over 24 years of experience in the plastic raw materials field, we not only understand the material properties but also grasp the actual pain points that customers encounter during the selection, procurement and delivery processes. Compared with directly connecting with brand merchants, we can offer you

・A more flexible supply system: Purchase as needed, no need to bear the pressure of large inventory.

・Cross-brand professional recommendations: Not limited to a single manufacturer, we comprehensively match the most suitable model from the customer's perspective.

・Technical data and selection guidance support: We have rich practical application experience in PESU and can assist you in quickly assessing feasibility and saving development time.

・Fast response + stable delivery time: We have established stable channels in the upstream of the supply chain, which can effectively mitigate the risk of cyclical fluctuations.

・One-stop service: Full-process connection from selection, sample, quotation to order placement, no need for multiple communication.

The inherent performance of PESU PESU 3010 MPESU 3010 MR Determines its material value, and we are committed to truly implementing this value in your products, processes and market goals. Welcome to contact us to obtain samples or technical data and explore more possibilities together.

[Recommended model suggestions]

・View details of the same series enhanced type: PESU 2010 G6 material >>

・Explore the Transparency grade PESU: PESU 1010 Transparent Polyethersulfone >>

・Learn more about PESU applications: Trends and Typical Cases of Polyethersulfone Material Applications >>