PRODUCTS

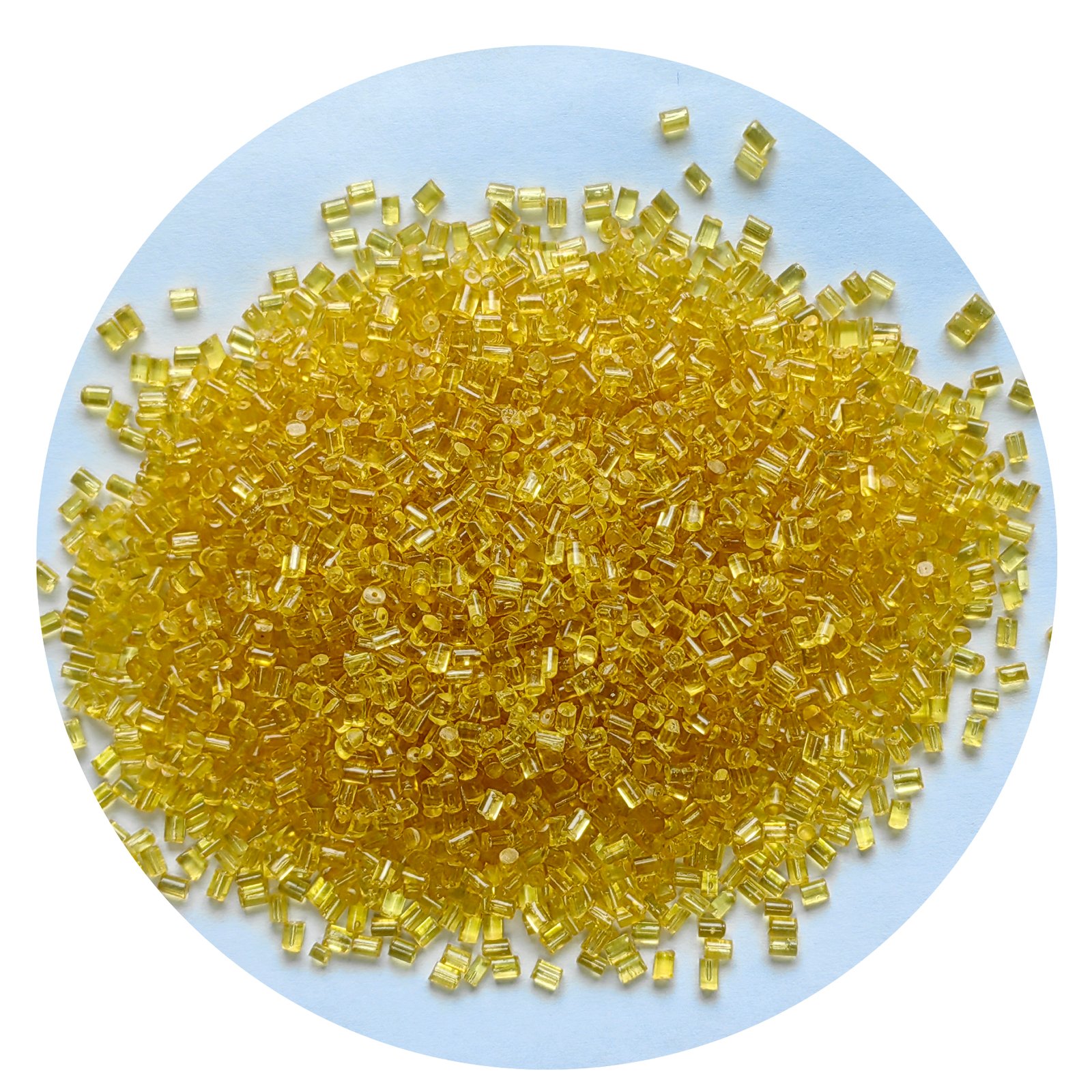

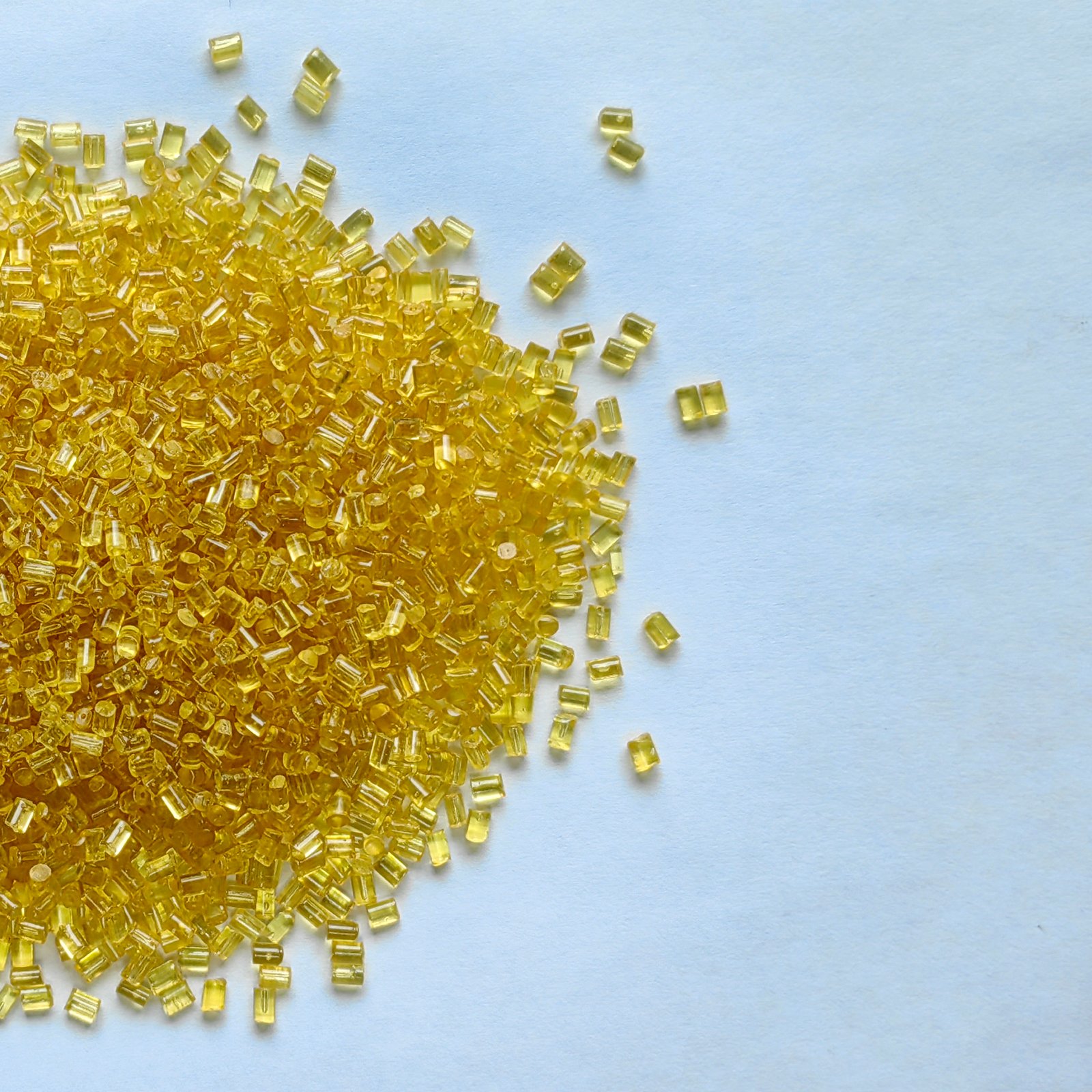

PESU 2020 P SR Polyether Sulfone for Coating and Membrane

Product Struction

What is Polyether Sulfone

As material applications become increasingly sophisticated and multifunctional, traditional granular thermoplastic engineering plastics are no longer sufficient to meet the needs of some cutting-edge industries. The new polyether sulfone material, PESU 2020 P SR, provided in the form of film or coating, is providing new solutions for functional coatings, membrane materials and high-end modified plastics with its unique properties.

01 | Material analysis: Starting from the structure of Polyether sulfone, understand the special features of PESU 2020 P SR

Polyether sulfone (polyethersulfone) is a non-crystalline polymer with high glass transition temperature (Tg), good thermal stability and chemical inertness. Its molecular skeleton contains both flexible ether bonds (-O-) and rigid sulfone groups (-SO₂-). This makes it both flexible and able to maintain stable performance in high temperature and organic chemical environments.

As a film/sheet grade material in BASF's polyether sulfone products, PESU 2020 P SR is particularly suitable for the following types of processing or application methods:

・Dip Coating

・Knife Coating

・Functional membrane preparation (separation membrane, diaphragm, interface layer)

・Compounded with other materials to form a high value-added membrane structure

02 | Technical highlights: Material potential behind the data

| Property | Typical Value | Functional Interpretation |

| Average Molecular Weight (Mw) | 55,000 g/mol | Ensures film continuity, supports uniform coating and membrane strength |

| Intrinsic Viscosity | 59 cm³/g | Suitable for solvent-based dispersion systems, promotes film formation and interlayer adhesion |

| Bulk Density | 0.3 g/cm³ | Well-dispersed in powder or granule form; easy for storage and handling |

| Equilibrium Water Absorption | 1.0% | Maintains dimensional stability in high-humidity environments; suitable for membranes and microporous film processing |

These data show that PESU 2020 P SR is not a molded plastic in the traditional sense, but a structural and functional polymer carrier designed for "functional coating systems".

03 | Application innovation: How does PESU film empower future coating and diaphragm technologies?

1️⃣ Heat-resistant coating for battery separators

As the safety requirements for lithium batteries continue to increase, conventional PE and PP separators may melt or shrink during thermal runaway. The heat-stable coating prepared with PESU 2020 P SR can provide:

・Dimensional stability at 300°C

・Anti-melt puncture protection

・Higher electrolyte wettability

👉 Many separator companies have explored using it as a coating resin to improve the "delayed combustion" ability of lithium batteries after thermal runaway.

2️⃣ Interface treatment of medical-grade separation membranes or conductive layers

PESU has natural biocompatibility and chemical resistance and can be used to prepare:

・Medical ultrafiltration membranes (blood purification, virus retention)

・Implant device coatings or biosensor membranes

・Base membranes in thin film sensors

👉 Using PESU 2020 P SR, a coating system with a uniform thickness of less than 50μm can be prepared without sacrificing stability, thereby improving the accuracy of device integration.

3️⃣ High-end structural modification carrier

In addition to independent use, PESU 2020 P SR can also be used as a functional additive or interface coupling layer material for other engineering plastics to achieve:

・Interface bonding enhancement with reinforcing materials such as carbon fiber and aramid

・As an anti-stress cracking factor in PA, PPS, and PEEK modification

・As an intermediate buffer layer in aviation-grade composite materials to improve interlayer toughness

04 | Market trends: Why is Polyether sulfone material so popular?

・Green and sustainable: Compared with traditional fluorine-containing coatings, PESU does not contain halogens and is easier to recycle.

・Policy-driven: Flame-retardant film layers for new energy batteries and electronic devices have become the focus of new regulations.

・Transformation of the film industry: From low-functional protection to high-performance interface regulation, PESU film is filling the application gap between PC and PPS.

05 | How can we help you get the most suitable polyether sulfone material?

As a trader focusing on high-end engineering plastic particles and coating materials, we provide:

✅ Support for all models of BASF's original PESU series

✅ Material data sheets, coating experimental plans, sample delivery services

✅ Modification assistance: support for blending experiments and development with PVDF, PAN, PES, etc.

✅ Global supply chain collaboration, stable delivery cycle, support for small batches during development

Conclusion: PESU 2020 P SR is not only a film, but also the underlying structural language of high-precision manufacturing

The story of polyethersulfone has never been just "high temperature resistance". It is deeply embedded in the core material system of new energy, biomedicine, and advanced manufacturing in different forms. PESU 2020 P SR is an underestimated potential star in this trend.

📌 If you are developing high-temperature diaphragms, new ultrafiltration membranes, or looking for interface coating solutions, please contact us for samples and detailed information. Let the power of Polyether sulfone drive the technological breakthrough of your products.

【Related Recommendations】

PESU 2010 G6: Glass Fiber Reinforced pesu plastic for Electrical Components Learn more>

PESU 1010: Unfilled, Flame-Retardant Polyethersulfone for Precision Injection Parts Learn more>

What Material Is PES? Industry Uses & Future Trends of PES Material Learn more>