PRODUCTS

PESU 2010 G6 Guide | Glass Fiber Reinforced PESU Plastic

Product Struction

What is PESU Plastic

Today, with the continuous breakthroughs in materials science, an engineering plastic that was once regarded as "high-end special" is quietly entering the core components of new energy vehicles, electrical and electronic products, and even industrial printing manufacturing - it is PESU (polyethersulfone), and the star product BASF PESU 2010 G6 is becoming the technical support point of this trend of change.

1. What is PESU plastic? Not only a synonym for "high temperature resistance"

PESU, or Polyethersulfone, is a high-performance representative of polysulfone plastics. Its chemical structure contains stable ether bonds (–O–) and sulfone groups (–SO₂–), which give it excellent thermal stability, dimensional stability, mechanical strength and chemical inertness.

Compared with traditional engineering plastics, the advantages of PESU plastic are not only heat resistance, but also include:

・Long-term temperature resistance up to 180°C, short-term resistance over 220°C

・Maintain rigidity and strength at high temperature, minimal creep

・Excellent electrical insulation performance

・Flame retardant performance can reach V-0 level without adding additives

・Can be used in medical and high-clean environments, resistant to steam sterilization

These characteristics make PESU one of the irreplaceable core materials in many "next generation application" solutions.

2. Why is PESU 2010 G6 the first choice for technical engineers?

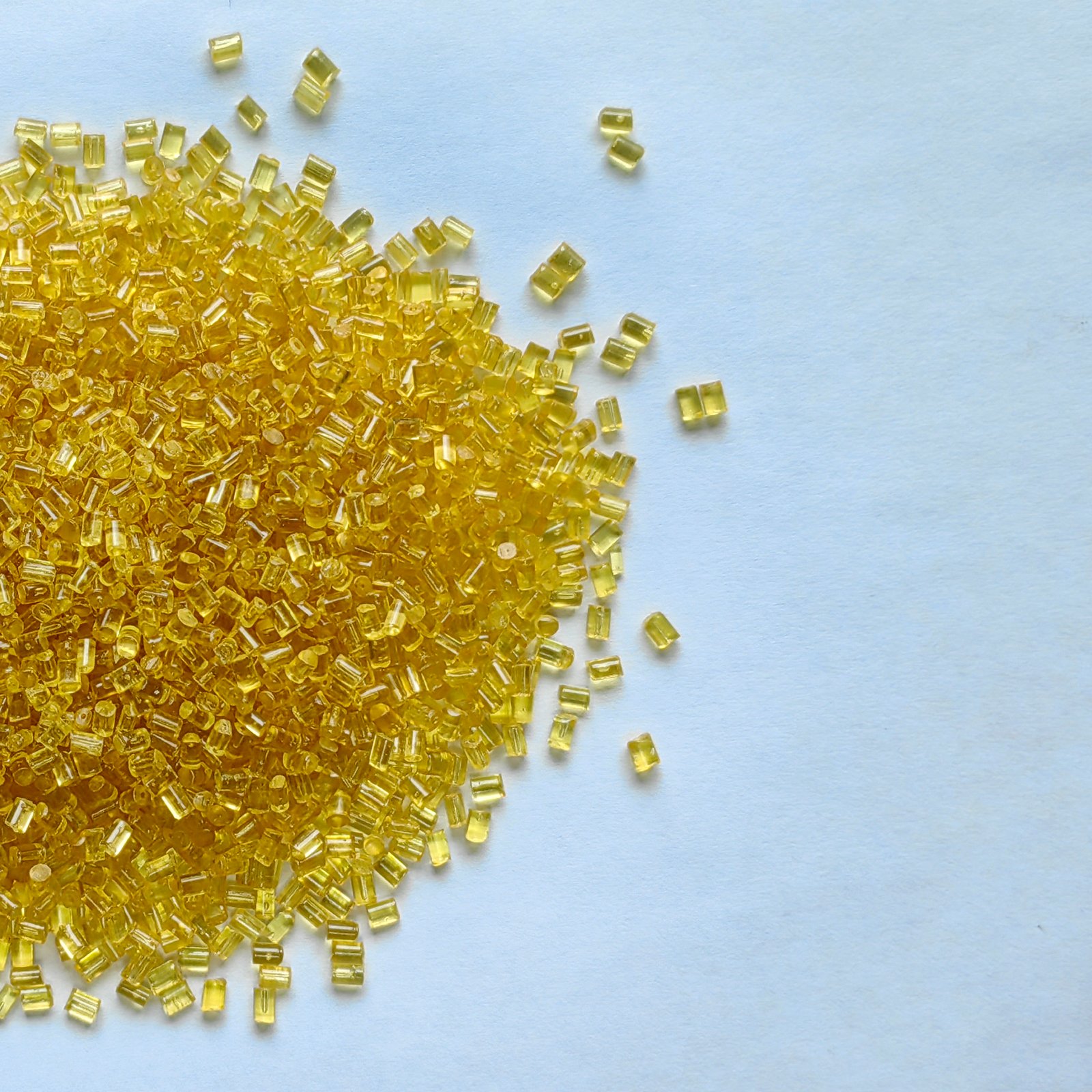

BASF's PESU 2010 G6 plastic is a 30% glass fiber reinforced polyethersulfone material that combines mechanical strength, flame retardant safety and dimensional stability. It is a "hardcore warrior" among PESU plastic.

| Property | Performance |

|---|---|

| Reinforcement Level | 30% glass fiber reinforced for enhanced rigidity |

| Tensile Strength | Up to 150 MPa (significantly higher than PA66 or PC) |

| Tensile Modulus | 9800 MPa, outstanding resistance to deformation |

| Thermal Resistance | HDT of 223°C, suitable for high-load components |

| Flame Retardancy | UL94 V-0 (both 1.5mm and 3.0mm thicknesses) |

| Electrical Insulation | Dielectric strength of 37 kV/mm, CTI 125V—ideal for high-voltage environments |

| Water Absorption | Only 0.60% at equilibrium, excellent dimensional stability |

✅ Simply put: it can withstand heat, tension, electricity and aging, and is a true industrial "endurance player".

3. Application in-depth scenarios: How does PESU 2010 G6 break through the multiple barriers of "high heat + high electricity + high rigidity"?

1️⃣ Electrical and electronic components:

・Printer moving parts, high-frequency connectors

・Insulation terminals, power device packaging shells

Traditional PC/PA materials are prone to deformation or insulation failure due to temperature rise, while PESU 2010 G6 still maintains electrical strength under 180°C continuous electrical load, especially suitable for components requiring high insulation levels in smart terminals and electrical control modules.

2️⃣ Industrial structural parts:

・Air filter support frame, heat-resistant connectors

・Corrosion-resistant structural skeleton inside the equipment

Its linear expansion coefficient is only 1.5E-5 cm/cm/°C, and the almost negligible thermal expansion and contraction make it suitable for connection components with complex structures and high dimensional requirements.

3️⃣ New energy and transportation components:

・BMS (battery management system) structural parts

・Onboard electronic connectors and insulating partitions

New energy vehicles emphasize lightweight and high safety. PESU 2010 G6 not only meets the flame retardant requirements, but also has excellent mechanical strength. It is an excellent material solution to replace metal and traditional PA/PC.

4. PESU vs. other engineering plastics: Why does it stand out?

| Performance Aspect | PESU 2010 G6 | PC | PA66 | PPS | PEEK |

|---|---|---|---|---|---|

| Continuous Use Temperature | 180°C | 120°C | 100°C | 200°C | 260°C |

| Flame Retardancy | V-0 (self-extinguishing) | Additives required | Additives required | V-0 | V-0 |

| Stiffness / Strength | Very high | Moderate | Lower | High | Very high |

| Processability | Injection molding friendly | Good | Good | Requires tight control | Complex |

| Cost | Mid-to-high | Low | Low | Mid-to-high | Very high |

Conclusion: PESU 2010 G6 is a very good solution for "performance-cost" balance, especially in situations where strength and thermal stability are required.

5. Why choose us as a PESU plastic supplier?

As a professional engineering plastic granule trader, we not only sell materials, but also help customers achieve design goals and supply chain security:

✅ Authentic channel guarantee: BASF original packaging genuine goods, stable and traceable

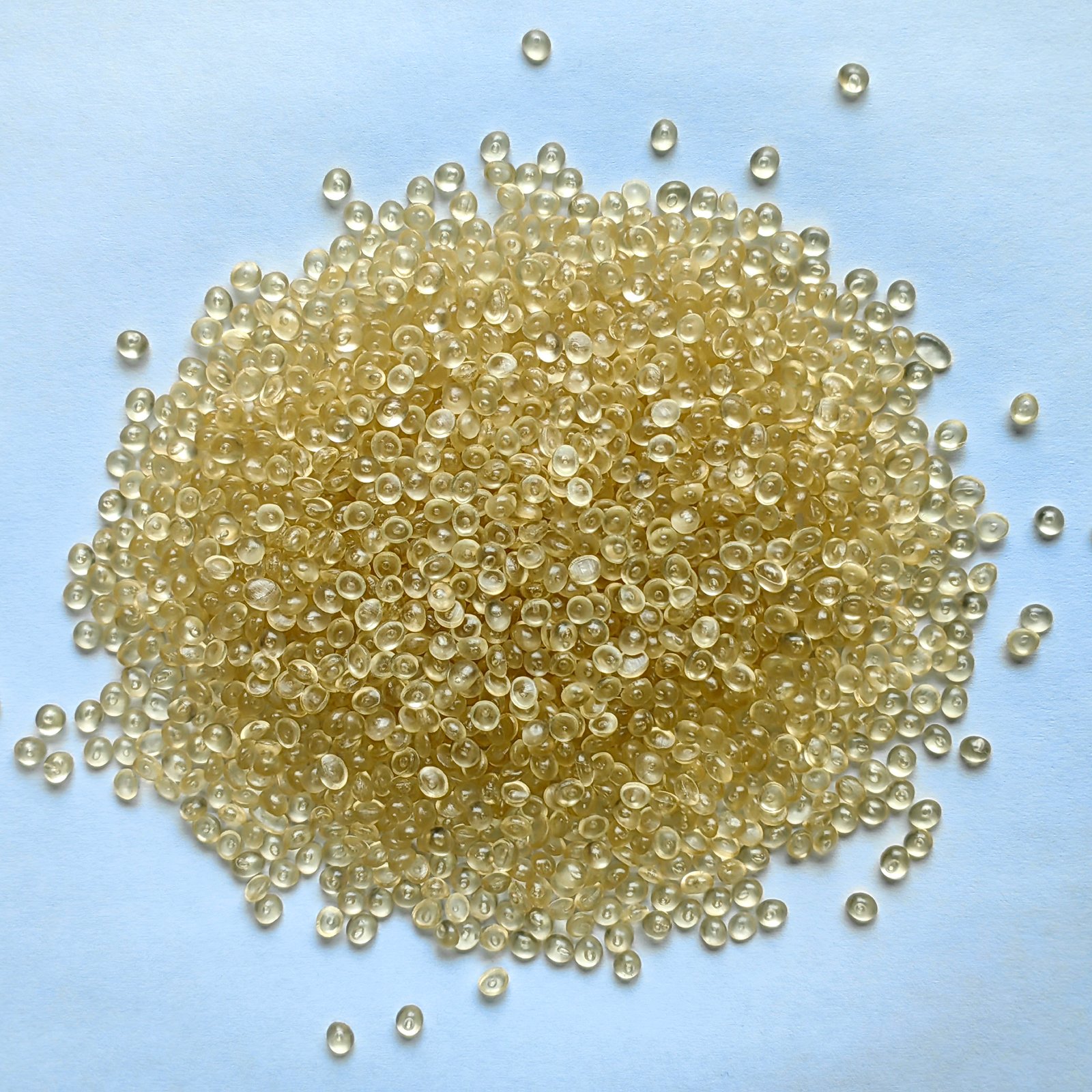

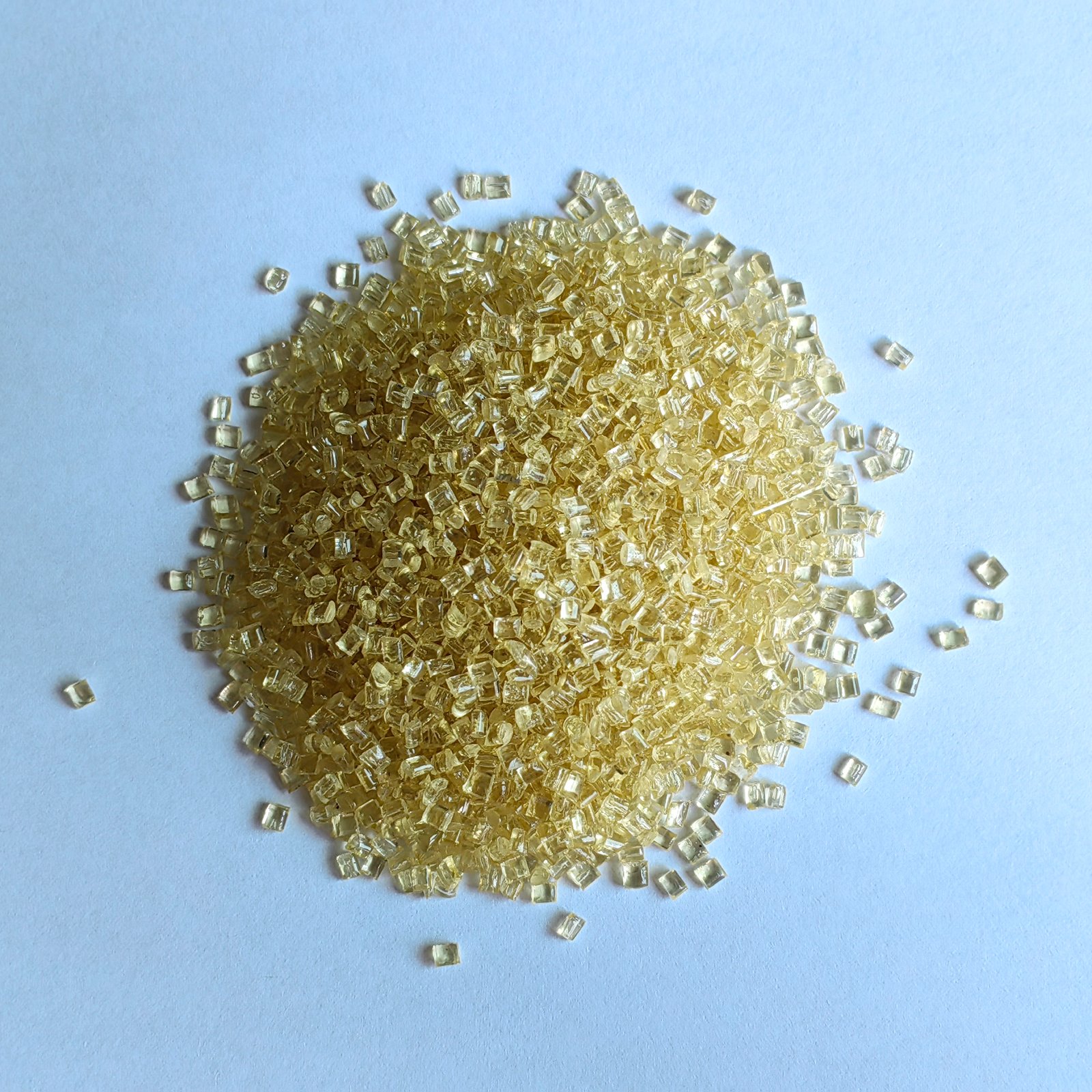

✅ Full coverage of models: transparent, enhanced, low MFR types are all available

✅ Small batch sample service: support proofing, test fast response

✅ Modification and customization service: can provide secondary color matching, adding additives, enhanced modification

✅ Fast delivery and technical support: equipped with an engineer team to assist in selection and optimization of mold parameters

Conclusion: PESU 2010 G6 is not only a material, but also a fulcrum of industrial evolution

In today's increasingly professional and extreme material selection, PESU 2010 G6 is not only a plastic, but also an engineering language, providing reliable structural support and functional output in multiple application fields of high performance, high safety and high stability.

If you are looking for an engineering plastic granule suitable for complex environments, high loads, and high temperature scenes, you might as well make PESU 2010 G6 one of your options. Welcome to contact us for samples, TDS, quotations and technical services!

【Related Recommendations】

PESU E0510 G9 SW 10112: Reinforced Polyethersulfone for Demanding Applications Learn more>

PESU 1010: Unfilled, Flame-Retardant Polyethersulfone for Precision Injection Parts Learn more>

What Material Is PES? Industry Uses & Future Trends of PES Material Learn more>