PRODUCTS

PA6 Plastic Material Overview | YH800 Properties and Data Sheet

Product Struction

What is PA6 Plastic Material

Among the many PA6 plastic material solutions, Yueyang Petrochemical's PA6 YH800 resin has become a cost-effective choice in injection moulding due to its good balance of fluidity and mechanical properties. It is not designed for extreme performance, but rather to meet the practical needs of industrial users for material compatibility, processing window tolerance and stability in complex moulding processes.

01 | Overview of resin properties

Medium viscosity design: Relative viscosity of 2.78, melt index of 38 g/10min, good flowability for injection moulding of thin-walled parts or complex structures.

Balanced mechanical properties: Tensile strength of 67 MPa, flexural strength of 89 MPa, impact strength of 6.0 kJ/m², which can meet the mechanical requirements of most standard industrial parts.

Processing adaptability: Melt temperature range of 220~225°C, moderate pre-drying conditions (moisture control within 0.07%), good compatibility with injection moulding equipment and moulds.

Good physical stability: Specific gravity of 1.156 g/cm³, residual monomer content is controlled within 0.5%, which contributes to dimensional stability and odour control during processing.

Low moisture absorption: Low moisture content (0.07%), effectively reducing common defects in injection moulding such as bubbles and silver lines.

02 | Analysis of wide range of applications

The physical design of YH800 is suitable to cover the following industries:

Household appliances: Hoover housings, blender holders, kettle internals, etc.

Industrial components: Non-structural connectors, module support plates, housing components

Automotive industry: Door interior panels, ventilation components, non-load-bearing functional parts

Consumer goods: Stationery, toy housings, injection moulded parts for daily necessities

Electrical applications: Wire channels, switch brackets, equipment housings, and other light-duty electrical products

This adaptability to cover both consumer and industrial applications is the key to the YH800's ability to remain competitive in the plastics sourcing market.

03 | PA6 Plastic Material YH800 Datasheet

| Mechanical behavior | Condition | Standard | Value | Unit | |||

| Flexural Strength | GB/T 1040 | 89.0 | MPa | ||||

| Flexural Modulus | GB/T 1040 | 1990 | MPa | ||||

| Tensile Strength | GB/T 1040 | 67.0 | MPa | ||||

| Charpy Notch Impact | GB/T 1043 | 6.0 | kJ/m² | ||||

| Thermal | Condition | Standard | Value | Unit | |||

| Melting Temperature | INTERNAL METHOD | 220~225 | °C | ||||

| Physical property | Condition | Standard | Value | Unit | |||

| Moisture Content | FZ-T51004 | 0.07 | % | ||||

| Monomer Content | FZ-T51004 | 0.5 | % | ||||

| Density | GB/T 1033 | 1.156 | g/cm³ | ||||

| Melt Index | GB/T 3682 | 38.0 | g/10min | ||||

| Relative Viscosity | FZ-T51004 | 2.78 | |||||

04 | On-site Processing Advantages

As a medium-viscosity, non-reinforced PA6 material, YH800 has the following processing-friendly features:

Short pre-drying time: Compared with high-viscosity or reinforced PA6, drying is more efficient and saves pre-treatment time;

Smooth cavity filling: Good flowability facilitates the moulding of thin-walled parts and complex structures;

Wide process window: Wide range of adaptations covering a wide range of injection moulding machines and process parameters;

Smooth demoulding: Lubricant and release agent formulation reduces mould residue and facilitates automated production.

05 | Our service commitment as a trader

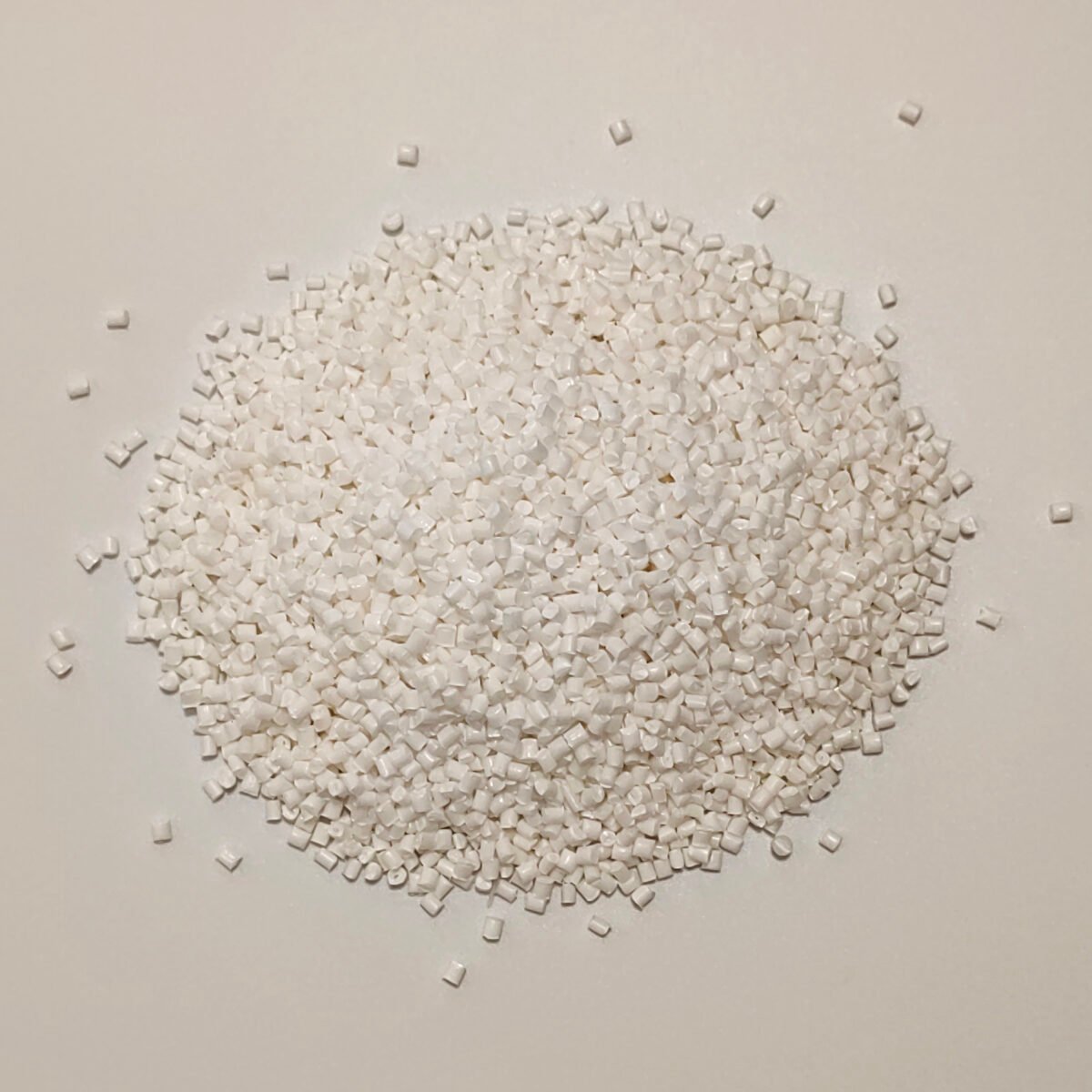

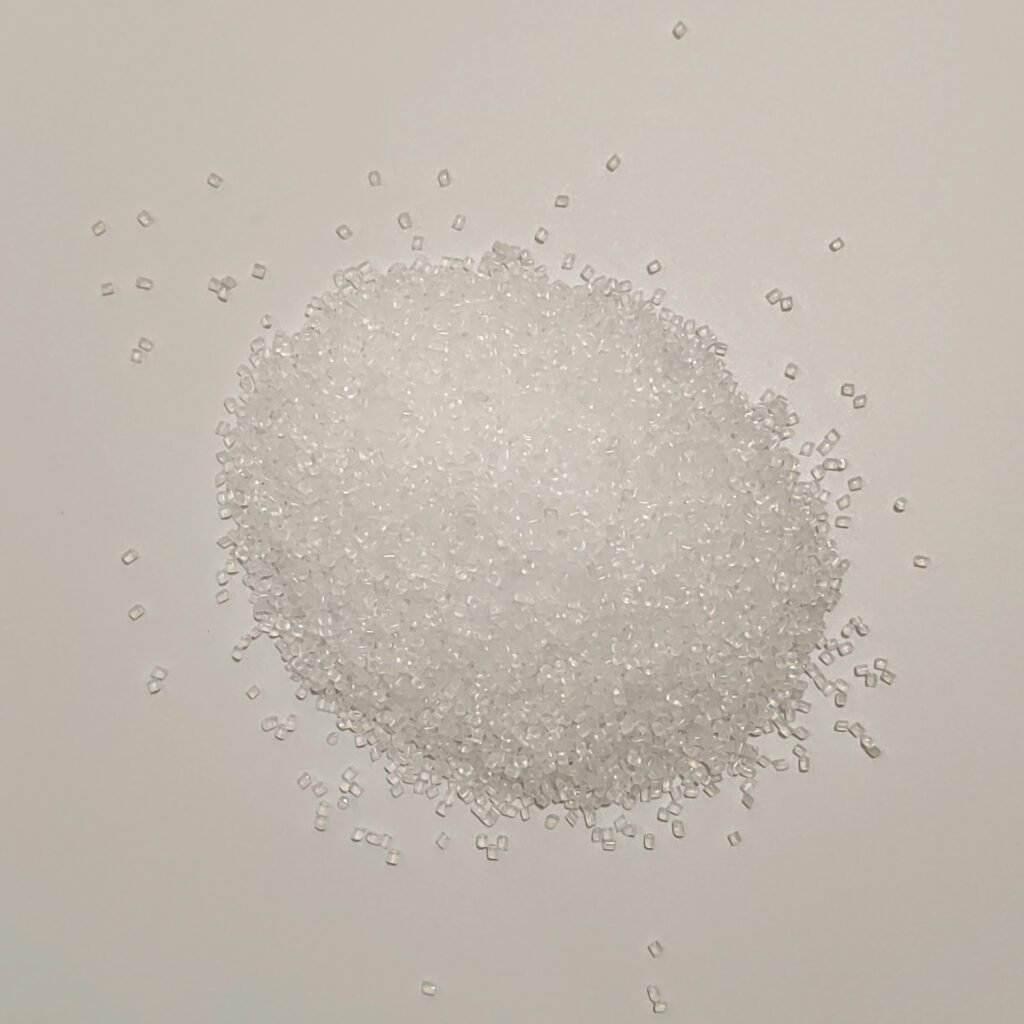

We not only provide stable supply of Yueyang Petrochemical's PA6 YH800 virgin plastic pellets, but also provide customers with solutions to the whole process from material selection to use, including:

✔ Provide technical information such as TDS, COA, MSDS, etc. of the products;

✔ Give drying suggestions, melt temperature setting range and mould temperature control suggestions;

✔ Assist customers in evaluating the suitability of their existing moulds, equipment and materials;

✔ Provide customised labelling, pallet stacking and reinforced packaging services for export customers.

06 | Sustainable Manufacturing Material Options

YH800 has no halogen or heavy metal additives in its raw material composition, making it an environmentally friendly material. Reduced mould residue and wear during processing also means:

✔ Lower equipment maintenance costs;

✔ Higher line stability;

✔ Better recycling processes and reduced environmental burden.

With global manufacturing companies emphasising ESG and sustainability, YH800 offers a friendlier base material option.

07 | Conclusion: A quality choice for general-purpose PA6 plastic material

As a practical medium-viscosity PA6 plastic material, Yueyang Petrochemical's PA6 YH800 offers good injection moulding efficiency, compatibility and process stability. It is an important raw material basis for manufacturing enterprises to reduce the overall cost while maintaining product consistency and stable delivery time.

We support small-batch samples, rapid delivery and long-term supply. Welcome to consult for samples and quotations. Let YH800 be your cost-effective material choice for your next project.

【Related Recommendations】

BASF PA6 B3K: Glass-Filled Nylon for Durable Electrical Components Learn more>

BASF PA6 B3EG6: 30% Glass Fiber Reinforced Nylon 6 for High-Flow Injection Molding Learn more>

PA6 B30S 000000: Fast-Cycle PA6 Resin for High-Precision Injection Applications Learn more>