PRODUCTS

PA6 Nylon B3EG6 30% GF for Electrical Insulation & Industrial Use

Product Struction

What is PA6 Nylon

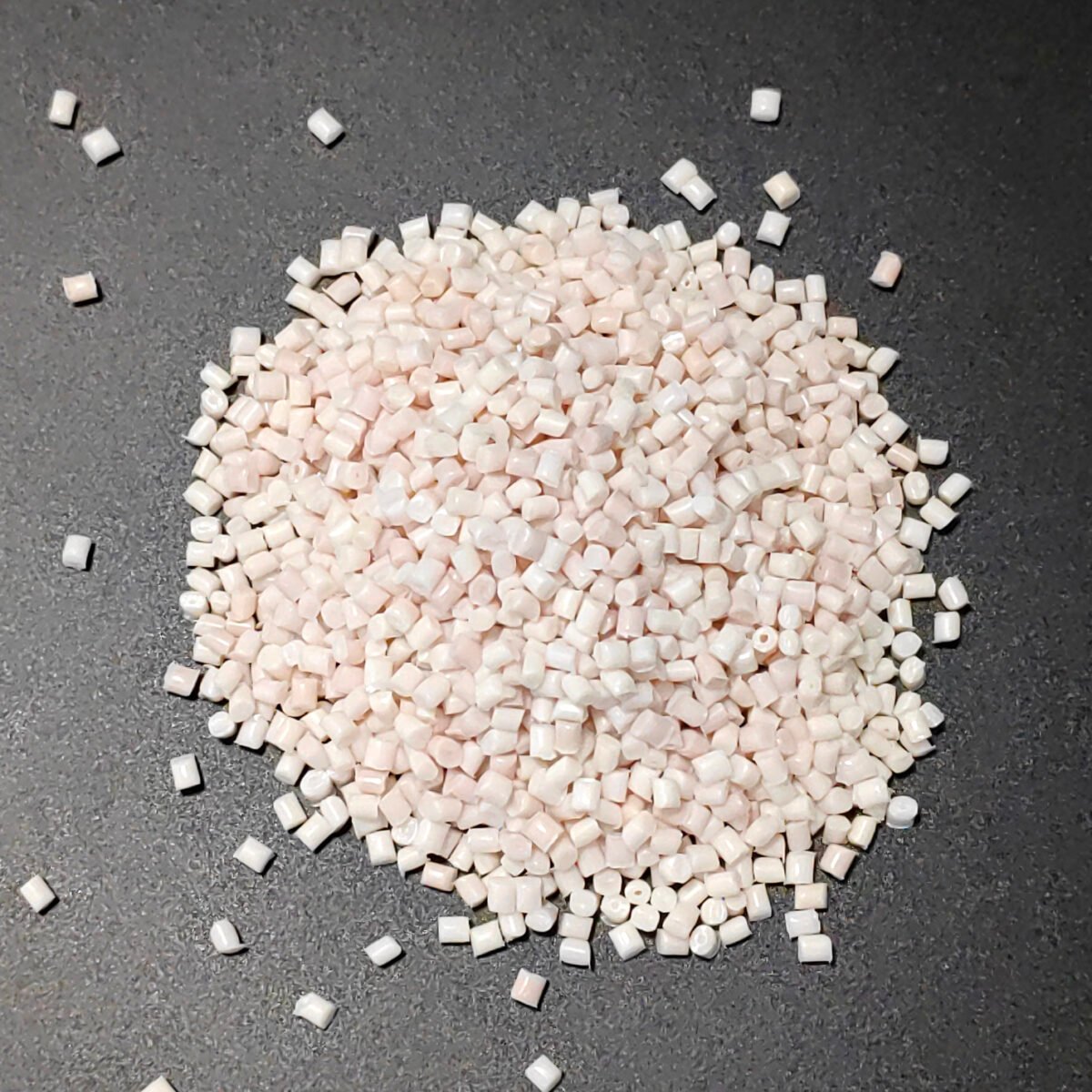

PA6 B3EG6 is a glass fiber reinforced nylon 6 (PA6 nylon) material launched by BASF, containing 30% glass fiber filling, with excellent structural strength, heat resistance and molding fluidity. Its material form is natural color granules, suitable for injection molding process, especially for complex, thin-walled, and engineering parts with high requirements for dimensional accuracy.

01 | Overview of PA6 Nylon B3EG6 Features

Enhanced formula: Containing 30% glass fiber, it improves mechanical properties and creep resistance, suitable for high-load applications.

Thermal stability system: It contains special heat stabilizers, which can withstand heat for a long time without aging, and is suitable for continuous high-temperature working environments.

Low viscosity and high fluidity: helps to fill precision moulds, optimising cycle time and productivity.

Excellent electrical insulation properties: high electrical resistivity, suitable for a variety of electrical structural components insulation needs.

Good weatherability and hot water resistance: adapt to outdoor, humid and hot and cold alternating working conditions.

Flame retardant grade UL94 HB: meets the basic safety requirements for flame retardancy in general industrial applications.

02 | Additive composition

Thermal stabilizer: enhances the long-term stability of the material at high temperatures

Lubricant and release agent: improves fluidity and surface quality, facilitates demolding and reduces mold loss

03 | Typical application directions

Electrical assemblies: connector housings, cable clamps, control panel brackets, etc.

Industrial parts: small gearboxes, support structures, housing injection molded parts

Outdoor equipment parts: high-strength components exposed to the natural environment

04 | PA6 Nylon B3EG6 Datasheet

| Electrical properties | Condition | Standard | Value | Unit | |||

| CTI | Solution A | IEC 60112 | 575 | ||||

| Dielectric | Constant 1MHz | IEC 62631-2-1 | 3.8 | 6.8 | |||

| Dissipation | Factor 1MHz | IEC 62631-2-1 | 0.023 | 0.22 | |||

| Surface | Resistivity | IEC 62631-3-2 | 1E10 | ||||

| Volume | Resistivity | IEC 62631 | 1E+13 | 1E10 | |||

| Flammability | Condition | Standard | Value | Unit | |||

| Flame | Rating All Color 1.5mm | UL94 | HB | ||||

| Flame | Rating All Color 3.0mm | UL94 | HB | ||||

| Flame | Rating All Color 6.0mm | UL94 | HB | ||||

| Mechanical behavior | Condition | Standard | Value | Unit | |||

| Charpy | Notch Impact 23°C 1eA | ISO 179 | 15 | 30 | |||

| Charpy | Notch Impact -30°C 1eA | ISO 179 | 11 | ||||

| Charpy | Notch Impact 23°C 1eA | ISO 179 | 15 | ||||

| Charpy | Un-notch Impact 23°C | ISO 179 | 95 | 110 | |||

| Charpy | Un-notch Impact -30°C | ISO 179 | 80 | ||||

| Charpy | Un-notch Impact 23°C | ISO 179 | 95 | ||||

| Elongation | Break | ISO 527 | 3.5 | 8 | |||

| Flexural | Strength | ISO 178 | 270 | 180 | |||

| Flexural | Modulus | ISO 178 | 8600 | 5000 | |||

| Izod | Notch Impact 23°C | ISO 180 | 15.5 | 20 | |||

| Izod | Notch Impact -30°C | ISO 180 | 11 | ||||

| Izod | Notch Impact 23°C | ASTM D256 | 150 | 300 | |||

| Tensile | Modulus | ISO 527 | 9500 | 6200 | |||

| Tensile | Strength Break | ISO 527 | 185 | 115 | |||

| Physical property | Condition | Standard | Value | Unit | |||

| Density | ISO 1183 | 1360 | kg/m³ | ||||

| Halogen | Content Cl、Br、I | 100 | ppm | ||||

| Melt | Index 275°C 5kg | ISO 1133 | 35 | cm³/10min | |||

| Shrinkage | 0.26 | % | |||||

| Shrinkage | Flow | ISO 294 | 0.21 | % | |||

| Shrinkage | xFlow | ISO 294 | 0.74 | % | |||

| Viscosity | Number 0.5% in 96% H2SO4 | ISO 307 | 140 | cm³/g | |||

| Water | Absorption 23°C Saturation In Water | ISO 62 | 6.3~6.9 | % | |||

Click here to download TDS for BASF PA6 Nylon B3EG6

05 | Molding and processing parameters

Processing method: injection molding

Recommended drying temperature: 80–100°C, recommended drying for 4 hours to prevent hydrolysis

Melting temperature range: 260–290°C

Mold temperature: It is recommended to control between 80–100°C to obtain better surface quality

06 | Why choose PA6 Nylon B3EG6?

Compared with traditional unreinforced PA6 nylon materials, BASF B3EG6's reinforced structure can effectively improve the rigidity and stability of the product, especially for load-bearing parts and long-term electrical structural parts.

Its good molding fluidity also means higher production efficiency and less defective rate.

In terms of environmental protection, the material does not contain halogen and heavy metal additives, has a certain degree of recyclability, and meets the needs of modern industry for green manufacturing.

07 | What we can provide you?

We supply BASF PA6 B3EG6 virgin nylon particles all year round, support on-demand packaging, and have complete technical information, which can help customers quickly promote proofing and mass production.Whether you are looking for alternative materials or introducing reinforced PA6 nylon into your existing formula, we can provide samples and price support, and assist in solving practical problems during material selection and processing.

Feel free to contact us for TDS and free samples!

【Related Recommendations】

DSM PA6 1010C2: Flame-Retardant, Nucleated Nylon 6 for Injection Molding Applications Learn more>

BASF PA6 B3K: Glass-Filled Nylon for Durable Electrical Components Learn more>

Toray PA6 CM1017: Stable, Impact-Resistant Nylon 6 for Precision Parts Learn more>