Nylon (PA), as one of the most commonly used engineering plastics, possesses mechanical properties and heat resistance superior to those of general-purpose plastics. It also has excellent wear resistance, fatigue resistance, corrosion resistance, electrical insulation, and ease of processing, making it widely used in the automotive and mechanical engineering sectors.

In various automotive components, compared to polypropylene (PP), PA is more often used in parts that require higher performance, such as engine peripherals and various types of piping. Therefore, it is necessary to modify PA to enhance its mechanical properties and heat resistance, and to endow it with additional functional characteristics. This ensures that it better meets the application requirements of various structural and functional components in automobiles.

The modification of PA (polyamide) mainly involves physical modification methods, including fiber reinforcement modification, inorganic particle filling modification, blending modification, and foaming modification. For high-temperature-resistant PA, copolymer modification is also a commonly used modification technique.

I. Research on Modification Technology of General-Purpose PA for Automotive Use

1. Fiber Reinforced Modification

Fiber reinforcement modification is one of the most commonly used modification techniques, primarily aimed at enhancing the mechanical properties of polyamide (PA). The reinforcing fibers typically used are glass fibers (GF) and carbon fibers (CF). The mechanical properties of fiber-reinforced PA are closely linked to the type, length, and content of the fibers, as well as the interfacial bonding state between the fibers and PA. These properties are also deeply affected by the fabrication process. Compared to short fibers, continuous fibers and woven fabrics offer a greater improvement in the mechanical properties of PA, but their fabrication processes are more complex. Successful preparation of such fiber-reinforced modified PA composites is critically dependent on the thorough impregnation of the PA resin into the continuous fibers and woven fabrics.

Compared to short fibers, continuous fiber-reinforced thermoplastic composites possess higher comprehensive mechanical properties and have become a research focus and development priority in fields such as automotive manufacturing, rail transportation, and aerospace.

In contrast to single fibers, fiber weaves can enhance thermoplastic composites in multiple directions on a two-dimensional or three-dimensional scale. Moreover, compared to thermoset composites, fiber weave-reinforced thermoplastic composites have a shorter molding cycle, which results in relatively lower manufacturing costs. Additionally, they can be recycled multiple times, which is why they are increasingly being used in the automotive industry and other sectors.

In addition to CF (carbon fiber) and GF (glass fiber), basalt fiber (BF) can also be used to reinforce PA (polyamide). Researchers have used eco-friendly BF as a reinforcing material to prepare PA6/BF composite materials, aiming to address the issue of poor interfacial bonding between BF and the resin matrix.

2. Inorganic Particle Filler Modification

Inorganic particles are widely sourced, cost-effective, and can enhance certain properties of plastics, mostly used for plastic filling modification. However, most inorganic particles are not very compatible with the resin matrix in plastics, and generally require surface modification or the addition of compatibilizers to improve interfacial compatibility. By adding surface-treated inorganic particles to PA (polyamide) or introducing compatibilizers into inorganic particle-filled PA systems, the mechanical properties of PA can be significantly improved, making it suitable for applications in the automotive manufacturing sector and other fields. Additionally, inorganic particles can be added to fiber-reinforced PA systems to utilize the synergistic modification effects of inorganic particles and fibers.

Incorporating silica into PA6 (polyamide 6) to enhance its mechanical properties is a modification method that helps improve the performance of PA products used in automotive components.

Utilizing talcum powder to modify PA6 materials for automotive use aims to reduce material costs and enhance material performance. This modification can significantly improve the processability of PA6 composite materials and notably enhance tensile properties while maintaining the bending performance and thermal properties of pure PA6.

Incorporating graphene nanoplatelets into PA610 can be used to strengthen the mechanical and thermal properties of automotive PA610 materials.

3. Foaming Modification

Lightweighting is one of the main directions in current automotive development. By utilizing foaming technology to produce PA-based microcellular foamed materials, it is possible to achieve a significant lightweighting effect. The presence of microcellular pores also endows the PA material with characteristics such as sound insulation and thermal insulation, enhancing the application potential of PA materials in the automotive industry.

4. Blend Modification

Researchers have developed a new halogen-free flame retardant reinforced PA66/PA6 alloy for high-voltage connectors in electric vehicles, using a flame retardant system composed of aluminum diethylphosphinate and aluminum hypophosphite, with glass fibers (GF) as the reinforcing system. It was found that PA6 had a minimal effect on the flame retardancy of the alloy. As the content of PA6 in the alloy increased, the strength and modulus of the material decreased while the notched impact strength improved. After aging at 85°C and 85% relative humidity for 1000 hours, the water absorption rate of the alloy increased with the PA6 content, and the electrical insulation performance under high-temperature conditions gradually decreased as the PA6 content in the alloy increased.

Furthermore, by blending Acrylonitrile Butadiene Styrene (ABS) high rubber powder with PA6, a colored PA6/ABS alloy material for automotive use was prepared. Additionally, the rate of color change after thermo-oxidative aging was reduced by adding titanium dioxide. The prepared gray PA6/ABS alloy material has been successfully applied to accessories for children's car seats.

5. Heat Resistance Modification

Research has synthesized four types of maleic anhydride copolymer heat-resistant agents, which are poly(N-phenylmaleimide-alt-styrene) (PNS) with a rigid structure, carboxylated PNS (PCS), fluorinated PNS (PFS), and a cross-linkable structure of poly[N-(4-carboxyphenyl)maleimide-alt-triallyl isocyanurate] (PCT). The study examined the impact of these four heat-resistant agents on the thermal resistance of PA6 (polyamide 6). The results indicated that PCT-modified PA6 exhibited the best thermal resistance, followed by PFS (10%) modified PA6 (182.3°C), then PCS (10%) modified PA6 (164.8°C), and finally PNS (15%) modified PA6 (138.5°C).

II. Research on Modification Technology of High-Temperature Resistant PA for Automotive Use

Compared to conventional PAs (such as PA66 and PA6), high-temperature-resistant PAs can withstand higher temperatures and possess better heat resistance, making them more suitable for manufacturing automotive parts that require higher thermal performance. However, high-temperature PAs have a higher melting point and poorer moldability, and generally need to be copolymerized with other monomers to achieve good processing properties.

The PA6T and PA66 are mixed to form a salt in a polymerization kettle using a high-temperature, high-pressure solution polycondensation method, and then the PA6T/66 copolymer is produced through direct polycondensation. This copolymer is characterized by excellent heat resistance and good processability, making it suitable for use in automotive connectors.

A semi-bio-based high-temperature resistant copolymer PA, poly(terephthalic acid-pentamethylene diamine/co-adipic acid-pentamethylene diamine) (PA5T/56), was prepared through high-temperature solution polymerization. This semi-bio-based high-temperature resistant copolymer PA exhibits better thermal decomposition stability and char formation than PA6T/66, while its mechanical properties are comparable to those of PA6T/66. It can be applied in the field of automotive components that require high heat resistance and high strength.

A high-temperature resistant PA62 copolymer material was produced by polymerizing hexamethylene diamine, a copolymer diamine, and dibutyl oxalate through a method that involves solution polymerization followed by solid-state polycondensation. This type of material has a wide range of applications in areas such as around car engines where high heat resistance is required.

In view of the outstanding barrier properties, mechanical properties, heat resistance, and low water absorption of poly(m-xylylene adipamide) (PAMXD6), a glass fiber (GF) reinforced modified PAMXD6 composite material was prepared by incorporating antioxidant 1098 and lubricant TAF101. This GF reinforced PAMXD6 composite material features high strength, excellent dimensional stability, and superior surface properties (free of surface fibers).

III. Research on the Application of Modified PA in Automobiles

3.1 Piping Components

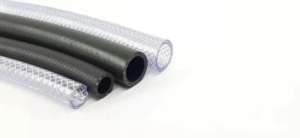

Piping components play a very important role in automobiles, with a wide variety of types including oil supply pipes, coolant pipes, brake lines, and more. In addition to requiring the corresponding materials to have good mechanical properties, automotive piping components should also possess excellent hydrolysis resistance, weather resistance, and high-temperature resistance characteristics.

PA, or polyamide, is a commonly used material for automotive tubing components. However, PAs with shorter carbon chains, such as PA6 and PA66, have a higher density of amide bonds and are prone to moisture absorption, which can adversely affect the material's strength and hydrolysis resistance.

Controlling the water absorption rate of PA has become a crucial factor in enhancing the performance of automotive PA tubes. In addition, PP, or polypropylene, has relatively poor heat resistance, which can negatively impact the high-temperature resistance of PA. Specialty engineering plastics, on the other hand, exhibit better heat resistance, and some varieties also have a lower water absorption rate, such as polyphenylene sulfide (PPS). By combining PPS with PA, a composite tube with excellent heat resistance and hydrolysis resistance can be obtained, making it suitable for use in automotive coolant pipelines.

Compared to short-chain PAs (PA6, PA66), long-chain PAs (PA12, PA612, PA11, PA1010, PA1012) have a lower amide bond density and exhibit a lower water absorption rate, making them the most commonly used PA materials for tubing components. The processing method for long-chain PA tubes is typically extrusion molding, and the molding process has a very important impact on the performance of the long-chain PA tubes.

PA can be manufactured into water pipes and used in the water cooling systems of new energy vehicles. PA can also be used to produce the barrier materials for automotive air conditioning hoses.

3.2 Other Automotive Components

Beyond the applications in pipeline components, PA (polyamide) materials are increasingly being used in peripheral components of automotive engines. This includes parts such as the turbocharged air cooler, intake manifold, intake port heat shield, turbo pipe resonator, and the hot-side turbo duct.

GF-reinforced PA exhibits excellent performance and can be used in a variety of automotive components. For instance, by incorporating inorganic mineral fillers and GF reinforcement through composite modification techniques, and adding components such as toughening agents, antioxidants, and lubricants, a meticulously formulated modified PA6 can be produced for use in car engine covers. GF-reinforced PA6 has already been applied in the steering column modules of the new BMW Series 3 to Series 7 cars, achieving a weight reduction of 20%. GF-reinforced PA66, with its good mechanical properties and low water absorption, can be used to manufacture automotive connectors.

Additionally, the application of various functionalized modified PA materials in automotive parts is becoming increasingly widespread. For example, radiators made of high thermal conductivity PA materials can be used in car rear fog lights. Compared to traditional aluminum radiators, not only is the weight reduced by 30%, but they also meet the cooling and mechanical performance requirements of LED rear fog lights, and production costs are reduced. This achieves the "plastic instead of aluminum" for automotive fog light radiators.

By combining polyamide (PA) with an appropriate viscosity and different types of polyolefin-based graft elastomers, it is possible to obtain PA66 materials with high flowability and low-temperature resistance. These materials can be used for the manufacture of automotive cable ties. PA can also be applied in the powertrain mounting systems of new energy vehicles. Compared to metal material mounting systems, there is a reduction in weight of approximately 37% to 50% and a cost reduction of about 10% to 28%, with relatively superior damping effects.