PRODUCTS

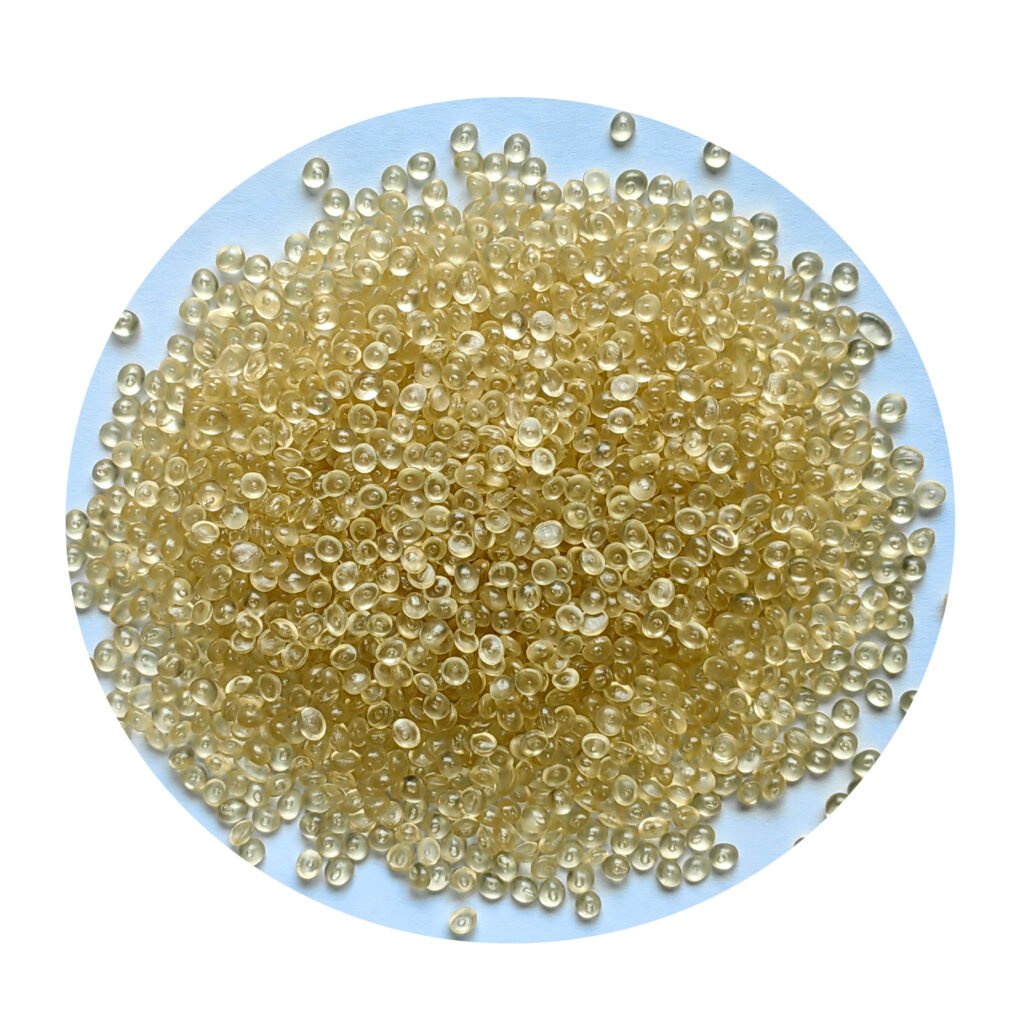

Non-enhanced PPSU 2010 Plastic Material Granules Overview

Product Struction

What is PPSU 2010 Plastic Material

PPSU 2010 is a polystyrene sulfone (PPSU) plastic material suitable for injection molding processes with moderate viscosity characteristics. The PPSU plastic material has not been enhanced and retains the excellent properties inherent in PPSU, such as good dimensional stability, high temperature resistance and chemical resistance, enabling it to maintain reliable mechanical properties and process stability in a variety of applications.

Due to its non-reinforced nature, PPSU 2010 has good fluidity in the molding process and is suitable for manufacturing products with uniform wall thickness and precise details.Its excellent heat resistance and hydrolysis resistance, so that it can be used in high temperature, humid heat and other harsh environment for a long time, without affecting the performance of the material.

PPSU 2010 plastic material is widely used in medical devices, food contact products, electronic components and other fields where high temperature and chemical resistance are required, providing stable and reliable material support for high-end industrial applications.

PPSU Plastic Material Data Sheet

| Mechanical behavior | Condition | Standard | Value | Unit | |||

| Charpy | Notch Impact -30°C | ISO 179 | 30 | kJ/m² | |||

| Charpy | Notch Impact 23°C | ISO 179 | 65 | kJ/m² | |||

| Charpy | Un-notch Impact -30°C | ISO 179 | NB | kJ/m² | |||

| Charpy | Un-notch Impact 23°C | ISO 179 | NB | kJ/m² | |||

| Elongation | Yield 23°C | ISO 527 | 7.8 | % | |||

| Izod | Notch Impact -30°C | ISO 180 | 25 | kJ/m² | |||

| Izod | Notch Impact 23°C | ISO 180 | 50 | kJ/m² | |||

| Tensile | Modulus 23°C | ISO 527 | 2250 | MPa | |||

| Tensile | Strength Yield 23°C | ISO 527 | 74 | MPa | |||

| Physical property | Condition | Standard | Value | Unit | |||

| Density | ISO 1183 | 1.29 | g/cm³ | ||||

| Melt | Index 360°C 10kg | ISO 1133 | 80 | cm³/10min | |||

| Water | Absorption 50RH | ISO 62 | 0.6 | % | |||

| Thermal | Condition | Standard | Value | Unit | |||

| HDT | 1.8MPa | ISO 75 | 195 | °C | |||

Click here to download TDS for PPSU 2010

PPSU Plastic Material Display

Ready to elevate your project with the best PPSU plastic materials? Talk to our team today!

【Related Recommendations】

PPSU R-7700: Flame-Retardant PPSU Resin for Aerospace & Aircraft Interiors Learn more>

PPSU R-5100 NT 15: Heat & Chemical-Resistant Resin for Medical, Aerospace Learn more>

PPSU R-5000 CL 301: Heat-Resistant PPSU Resin for Automotive Applications Learn more>