PRODUCTS

Metallocene Linear Low Density Polyethylene SP1520 Overview

Product Struction

MLLDPE SP1520 Introduction

mLLDPE SP1520 is a metallocene linear low-density polyethylene (mLLDPE) copolymer specifically designed for the blow molding process. It meets food contact grade standards and is suitable for a variety of film applications, performing well in packaging and agriculture.

1、MLLDPE Material Property

The MLLDPE SP1520 material has excellent low-temperature thermal sealing properties, enabling it to provide a more reliable seal in packaging applications. Its high impact strength ensures the film's durability and resistance to damage, while its low specific gravity helps to reduce material weight and increase production efficiency. In addition, the material uses a metallocene catalytic system, so that it has excellent mechanical properties, uniform molecular structure and stable processing properties.

2、MLLDPE Pellets Use

The mlldpe SP1520 plastic pellet is suitable for a variety of blow molded film applications, including food packaging, industrial packaging, agricultural film and more. Its good heat sealing and high strength make it an ideal choice for packaging bags, protective film, sealing films and other products. At the same time, the mlldpe material also performs well in agricultural film, and can be used for greenhouse film, mulch, etc., to improve crop protection and extend service life.

3、MLLDPE Resin Parameters

| Hardness | Condition | Standard | Value | Unit | |||

| Shore | Hardness D | JIS K7215 | 54 | ||||

| Mechanical behavior | Condition | Standard | Value | Unit | |||

| Charpy | Notch Impact | JIS K7111 | NB | kJ/m² | |||

| Elongation | Break | JIS K7161 | 350 | % | |||

| Flexural | Modulus | JIS K7171 | 160 | MPa | |||

| Tensile | Strength Break | JIS K7161 | 16 | MPa | |||

| Physical property | Condition | Standard | Value | Unit | |||

| Density | JIS K7112 | 913 | kg/m³ | ||||

| Environmental | Stress Crack Resistance | ASTM D1693 | 1000 | hr | |||

| Melt | Index | JIS K7210 | 2.0 | g/10min | |||

| Thermal | Condition | Standard | Value | Unit | |||

| Melting | Temperature | JIS K7121 | 116 | °C | |||

| Vicat | Softening Temperature | JIS K7206 | 96 | °C | |||

Click here to download TDS for mLLDPE SP1520

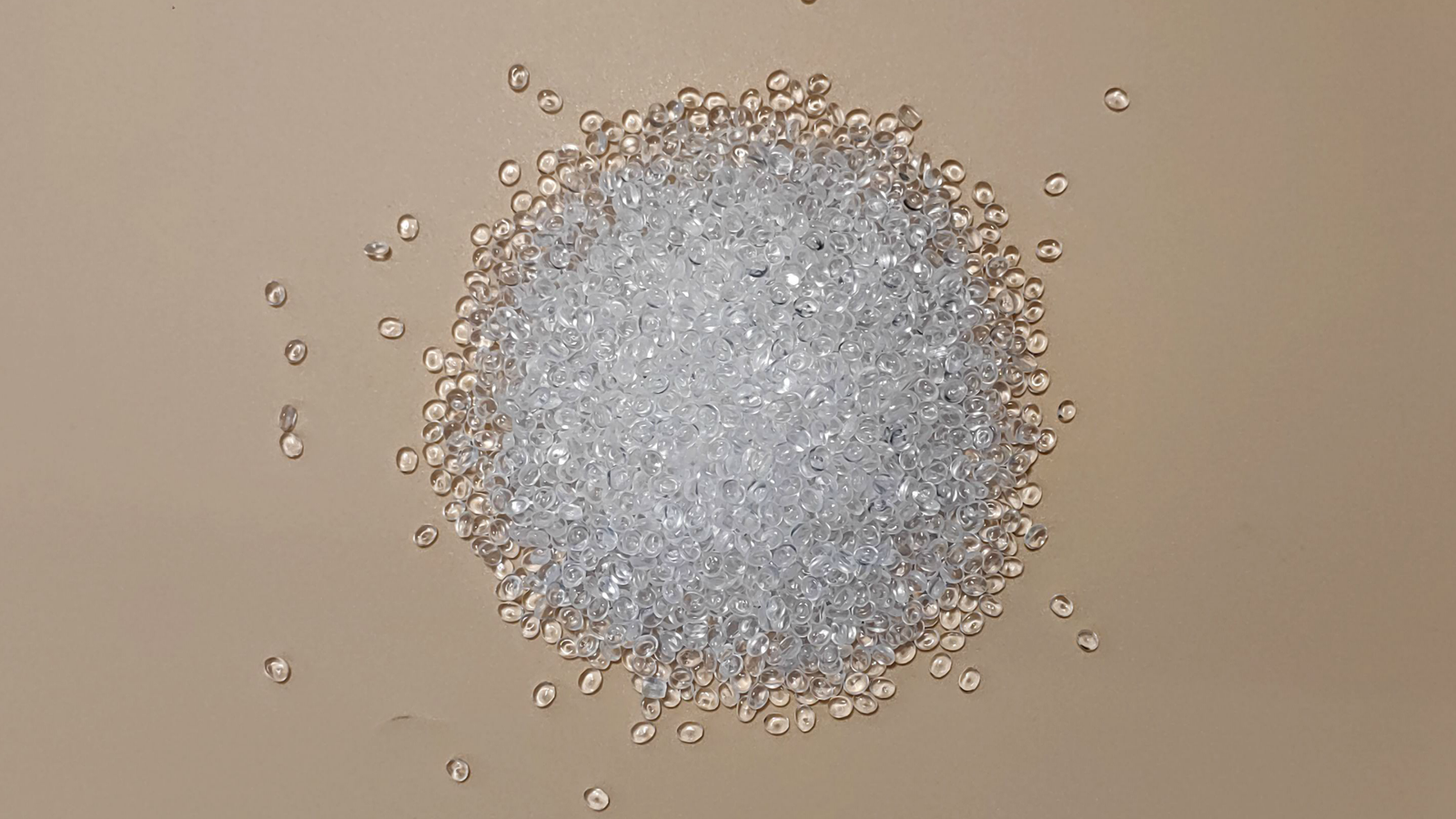

4、Metallocene LLDPE Granule Display

Explore the benefits of our material—contact us for more information!

【Related Recommendations】

mLLDPE 1018MF: High-Performance mlldpe Resin for Agricultural Packaging Learn more>

MLLDPE 3518CB: High-Performance mLLDPE for Extrusion & Blow Molding Learn more>

mLLDPE 1327MD: High-Performance Film-Grade mLLDPE for Food Packaging Learn more>