PRODUCTS

Introduction to High Gloss mLLDPE D173 with Data Sheet

Product Struction

MLLDPE D173 Introduction

mLLDPE D173 is a high-performance copolymer commonly used in film production. It offers excellent physical properties and is processed via extrusion, providing high efficiency for various packaging applications.

This material, primarily used for cast and stretch films, features a hexene copolymer that delivers superior clarity and gloss.Metallocene LLDPE D173 also provides excellent toughness, strength, and low density, which help reduce raw material consumption and lower production and transportation costs.

With strong heat sealing properties, mLLDPE D173 is ideal for packaging applications, ensuring secure seals that protect products during transport and storage. It is commonly used in high-end films such as greenhouse films, heavy-duty packaging films, shrink films, and stretch wrap films.

Its metallocene structure enhances stability, ensuring consistent performance in diverse conditions. These characteristics make mLLDPE D173 a cost-effective and reliable material for improving packaging quality and reducing production costs.

Metallocene LLDPE Parameters

| Optical performance | Condition | Standard | Value | Unit | |

| Gloss | 60° 25μm Cast Film | ASTM D2457 | 140 | ||

| Haze | 25.00μm Cast Film | ASTM D1003 | 2 | % | |

| Mechanical behavior | Condition | Standard | Value | Unit | |

| Elongation | Flow Break 25μm Cast Film | ASTM D882 | 500 | % | |

| Elongation | xflow Break 25μm Cast Film | ASTM D882 | 580 | % | |

| Elmendorf tear strength | Flow 25μm Cast Film | ASTM D1922 | 300 | g | |

| Elmendorf tear strength | xflow 25μm Cast Film | ASTM D1922 | 500 | g | |

| Tensile Strength | Flow Break 25μm Cast Film | ASTM D882 | 54 | MPa | |

| Tensile Strength | xflow yield 25μm Cast Film | ASTM D882 | 10 | MPa | |

| Tensile Strength | xflow Break 25μm Cast Film | ASTM D882 | 38 | MPa | |

| Tensile Strength | xflow yield 25μm Cast Film | ASTM D882 | 9 | MPa | |

| Tensile Modulus | Flow 25μm 1%Secant Cast Film | ASTM D882 | 103 | MPa | |

| Tensile Modulus | xflow 25μm 1%Secant Cast Film | ASTM D882 | 110 | MPa | |

| Friction Coefficient | 25μm Cast Film | ASTM D1894 | 1 | ||

| Drop hammer impact | 25μm Cast Film | ASTM D1709 | 450 | g/mil | |

| Thermal | Condition | Standard | Value | Unit | |

| Heat seal temperature | 25μm Cast Film 0.5s | ASTM F88 | 101 | °C | |

| Physical property | Condition | Standard | Value | Unit | |

| Density | ASTM D1505 | 0.918 | g/cm³ | ||

| Melt Index | 190°C 2.16kg | ASTM D1238 | 3.5 | g/10min | |

Click here to download TDS for mLLDPE D173

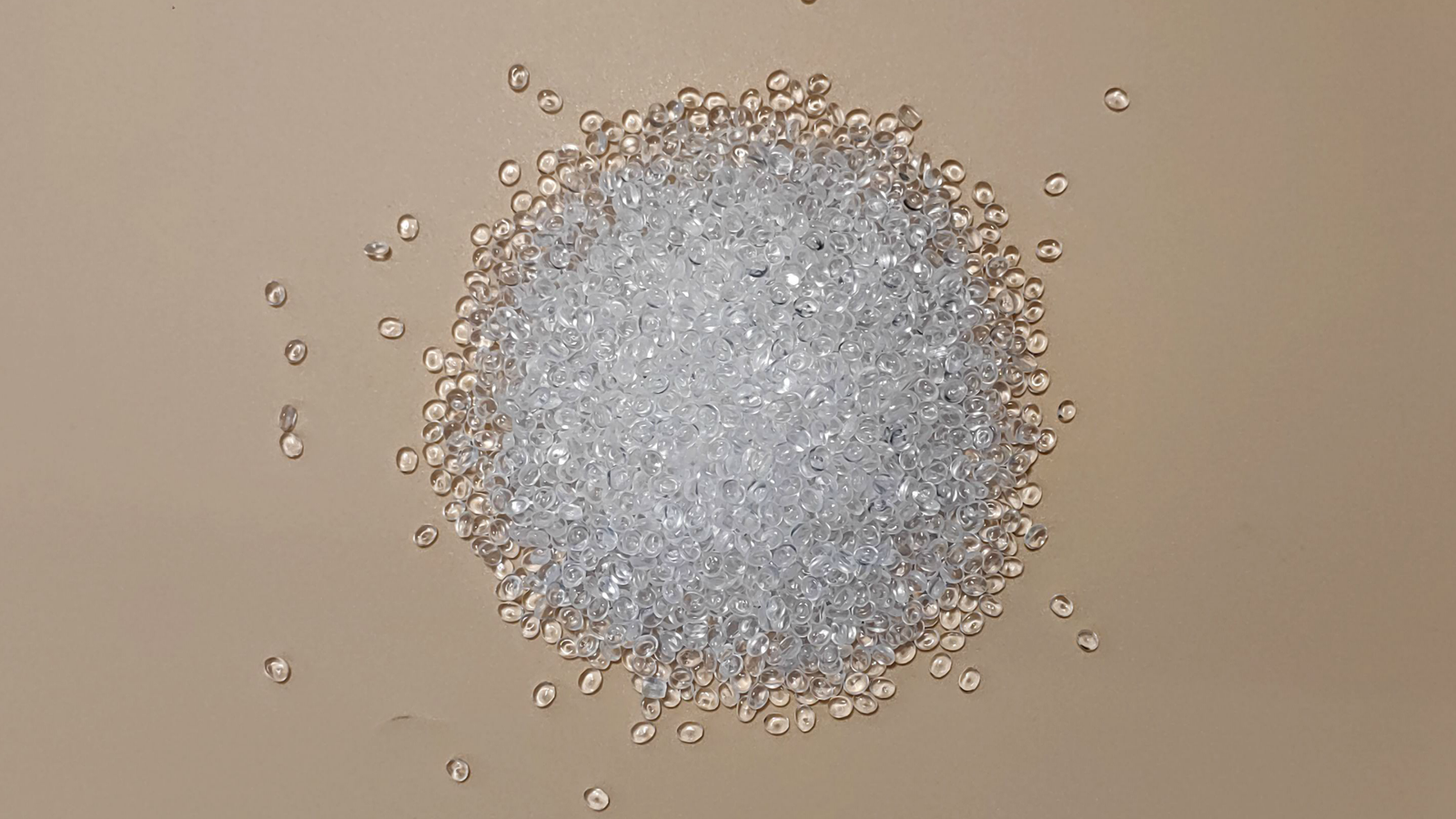

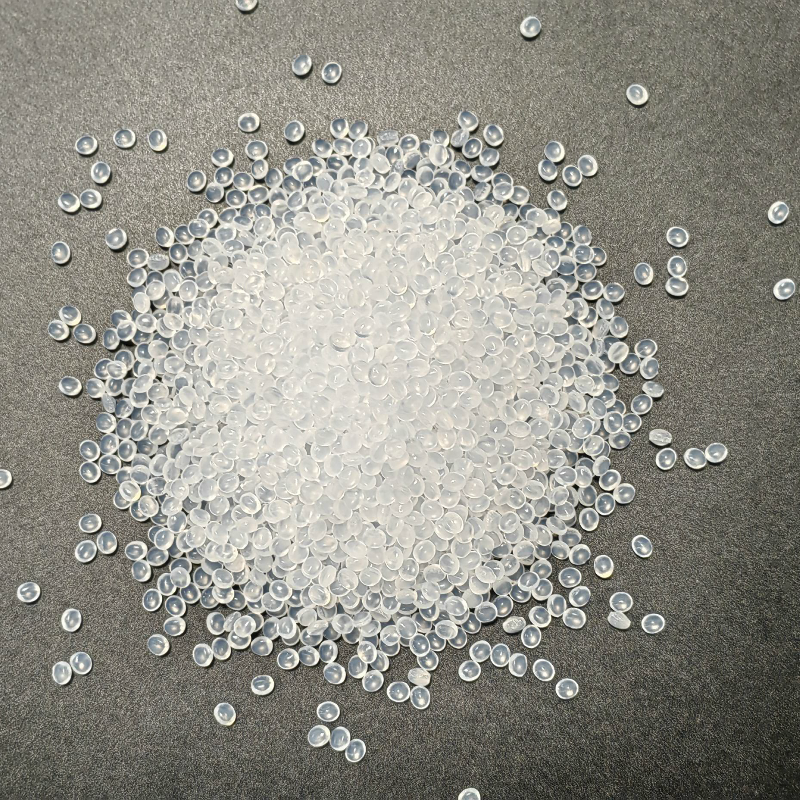

Metallocene Linear Low Density Polyethylene Display

Need to know the technical parameters of mLLDPE D173? Contact us for a TDS and request a free sample!

【Related Recommendations】

mLLDPE LL7810A: Superior Clarity mLLDPE for Packaging & Film Applications Learn more>

mLLDPE PF1315AZ: Flexible & Durable MLLFPE Resin for Flexible Packaging & Coating Learn more>

mLLDPE 8784MK: High Tough mLLDPE for Barrier Films & Liquid Packaging Learn more>