PRODUCTS

Introduction to High-Performance mLLDPE 1018MF and Datasheet

Product Struction

Metallocene LLDPE 1018MF Product Overview

In the plastic packaging industry, material selection plays a crucial role in determining product quality and performance. As a high-performance blown film copolymer, metallocene linear low density polyethylene 1018MF is widely recognized for its outstanding properties in food, industrial, and agricultural packaging. This article explores its key characteristics, applications, and processing methods.

1、Products Properties

mLLDPE 1018MF is an ethylene-1-hexene copolymer with the following advantages:

High Impact Strength:

Excellent toughness helps prevent packaging failure and product damage.

Superior Puncture Resistance:

Enhances durability, ensuring secure and reliable packaging.

Food-Contact Compliance:

Meets food safety standards, making it suitable for direct food packaging applications.

Slip and Anti-Blocking Additives:

Improves film handling and processing efficiency.

Thermal Stability:

Maintains consistent performance in high-temperature environments.

Processing Aids:

Reduces friction and enhances production efficiency.

2、Products Applications

Thanks to its outstanding properties, metallocene LLDPE 1018MF is extensively used in various industries, including but not limited to:

Food Packaging:

Ideal for barrier food packaging, bread bags, frozen films, multilayer laminates, and sealed packaging.

Industrial Packaging:

Used for heavy-duty bags, industrial liners, outer wrap films, and protective packaging.

Agricultural Films:

An excellent choice for agricultural applications requiring durability and weather resistance.

Sustainable Solutions:

Suitable for trash bags, stand-up pouches, and other eco-friendly packaging applications.

3、Processing Methods

mLLDPE 1018MF is designed for blown film extrusion, enabling efficient production of various flexible packaging materials. Common processing methods include:

Blown Film Extrusion:

Widely used for food, industrial, and agricultural films.

Multilayer Film Manufacturing:

Enhances barrier properties and expands application versatility.

4、Products Parameters

| Mechanical behavior | Condition | Standard | Value | Unit | |||

| Elmendorf | Tear Strength Flow | ASTM D1922 | 250 | g | |||

| Elmendorf | Tear Strength xFlow | ASTM D1922 | 470 | g | |||

| Elongation | Flow Break | ASTM D882 | 500 | % | |||

| Elongation | xFlow Break | ASTM D882 | 600 | % | |||

| Falling | Weight Impact Strength | ASTM D1709 | 460 | g | |||

| Puncture | Resistance | INTERNAL METHOD | 36 | N | |||

| Puncture | Resistance | INTERNAL METHOD | 1.8 | J | |||

| Secant | Modulus 1% Flow | ASTM D882 | 190 | MPa | |||

| Secant | Modulus 1% xFlow | ASTM D882 | 190 | MPa | |||

| Tensile | Strength Flow Yield | ASTM D882 | 9.4 | MPa | |||

| Tensile | Strength xFlow Yield | ASTM D882 | 9.4 | MPa | |||

| Tensile | Strength Flow Break | ASTM D882 | 50 | MPa | |||

| Tensile | Strength xFlow Break | ASTM D882 | 43 | MPa | |||

| Optical performance | Condition | Standard | Value | Unit | |||

| Gloss | 45° | ASTM D2457 | 39 | ||||

| Haze | ASTM D1003 | 18 | % | ||||

| Physical property | Condition | Standard | Value | Unit | |||

| Density | ASTM D1505 | 0.918 | g/cm³ | ||||

| Melt | Index 190°C 2.16kg | ASTM D1238 | 1.0 | g/10min | |||

| Thermal | Condition | Standard | Value | Unit | |||

| Melting | Temperature Peak | INTERNAL METHOD | 119 | °C | |||

Click here to download TDS for mLLDPE 1018MF

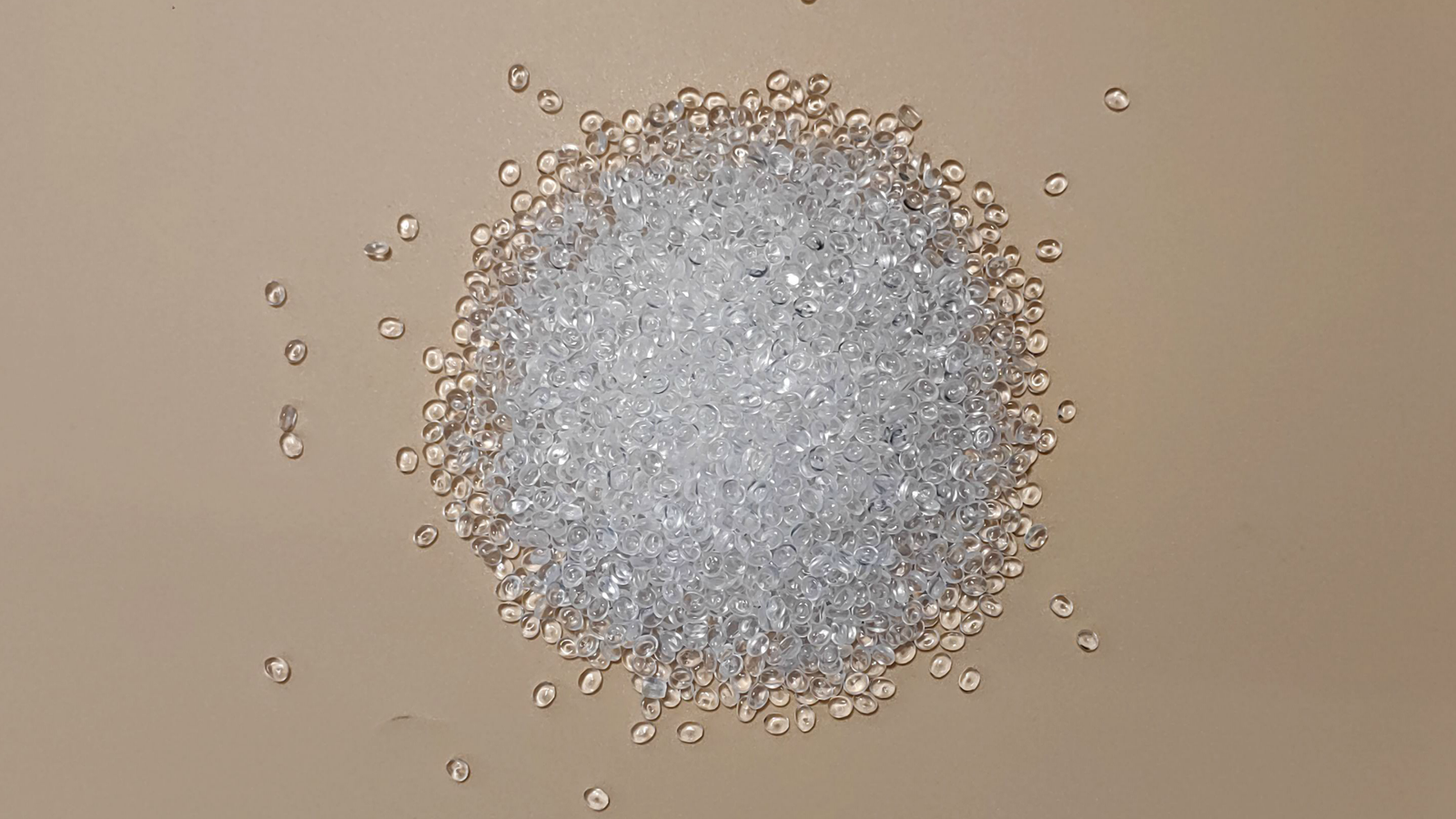

5、Products Display

If you're looking for a premium blown film metallocene linear low density polyethylene resin, mLLDPE 1018MF is the ideal solution. Contact us today for more details and pricing!

【Related Recommendations】

MLLDPE XP9100: High-Performance mLLDPE for Blow Molding & Packaging Learn more>

mLLDPE SP0540: High-Performance metallocene LLDPE for Film Extrusion Learn more>

mLLDPE SP1520: High-Performance mlldpe granule for Agricultural Films Learn more>