PRODUCTS

Metallocene mLLDPE LL7835A injection molding grade Heavy duty film application plastic raw material

Product Struction

Metallocene Linear Low-Density Polyethylene Introduction

Metallocene linear low-density polyethylene (mLLDPE) is an innovative high-performance thermoplastic that has garnered significant attention. Produced using metallocene catalysts, this material outperforms traditional linear low-density polyethylene (LLDPE) made with Ziegler-Natta catalysts. Among the premium products in the mLLDPE family, MLLDPE LL7835A stands out for its exceptional performance and wide range of applications.

Compared to conventional LLDPE, mLLDPE has a lower melting point and a narrower melting range, making it more flexible and efficient during processing. MLLDPE LL7835A excels in toughness, transparency, thermal adhesion, and low odor, with the added benefit of a low heat-sealing temperature. Its outstanding mechanical properties stem from its unique molecular chain structure, which enhances impact and tear resistance. In practical applications, MLLDPE LL7835A meets the stringent mechanical strength and gas barrier requirements of fields such as food and pharmaceutical packaging.

From a technical standpoint, the performance metrics of MLLDPE LL7835A are impressive. For instance, its 25-micron-thick film exhibits tensile strength and dart drop impact strength that surpass industry averages. Additionally, its optical properties, such as gloss and low haze, improve the visual appeal of finished products, making it especially suitable for high-transparency packaging materials.

MLLDPE LL7835A is also highly favored for its excellent processability. Its melt flow rate and recommended processing temperature range ensure stable performance in processes like blow molding and extrusion, enhancing production efficiency and product quality. Importantly, this material maintains excellent mechanical properties even when film thickness is reduced, supporting cost control and environmental sustainability goals for businesses.

Currently, MLLDPE LL7835A has been widely adopted in applications such as food packaging, industrial packaging, and construction materials. Whether used in single-layer films or multilayer composite films, its performance meets the demands of various high-end packaging applications. Its gas barrier and corrosion resistance properties also hold significant promise in pharmaceutical and agricultural film sectors.

As a high-performance metallocene polyethylene with broad applications, MLLDPE LL7835A is driving the packaging industry toward greater efficiency and environmental sustainability.

Metallocene Linear Low-Density Polyethylene Datasheet

| Blow Molding | Condition | Standard | Value | Unit | ||

| Die | Temperature | 170~190 | °C | |||

| Melt | Temperature | 160~180 | °C | |||

| Mechanical behavior | Condition | Standard | Value | Unit | ||

| Elongation | Flow Break 25μm Blown Film | ASTM D882 | 850 | % | ||

| Elongation | xFlow Break 25μm Blown Film | ASTM D882 | 900 | % | ||

| Falling | Weight Impact Strength 25μm Blown Film | ASTM D1709 | 140 | g | ||

| Tearing | Strength Flow 25μm Blown Film | ASTM D1922 | 140 | g | ||

| Tearing | Strength xFlow 25μm Blown Film | ASTM D1922 | 180 | g | ||

| Tensile | Modulus Flow 25μm 1% Secant Blown Film | ASTM D882 | 230 | MPa | ||

| Tensile | Modulus xFlow 25μm 1% Secant Blown Film | ASTM D882 | 250 | MPa | ||

| Tensile | Strength Flow Break 25μm Blown Film | ASTM D882 | 45 | MPa | ||

| Tensile | Strength xFlow Break 25μm Blown Film | ASTM D882 | 40 | MPa | ||

| Optical performance | Condition | Standard | Value | Unit | ||

| Gloss | 45° 25μm Blown Film | ASTM D2457 | 27 | |||

| Haze | 25μm Blown Film | ASTM D1003 | 19 | % | ||

| Physical property | Condition | Standard | Value | Unit | ||

| Density | ASTM D792 | 0.920 | g/cm³ | |||

| Melt | Index 190°C 2.16kg | ASTM D1238 | 3.5 | g/10min | ||

| Thermal | Condition | Standard | Value | Unit | ||

| Melting | Temperature | ASTM D3418 | 118 | °C | ||

| Vicat | Softening Temperature | ASTM D1525 | 107 | °C | ||

Click here to download TDS for mLLDPE LL7835A

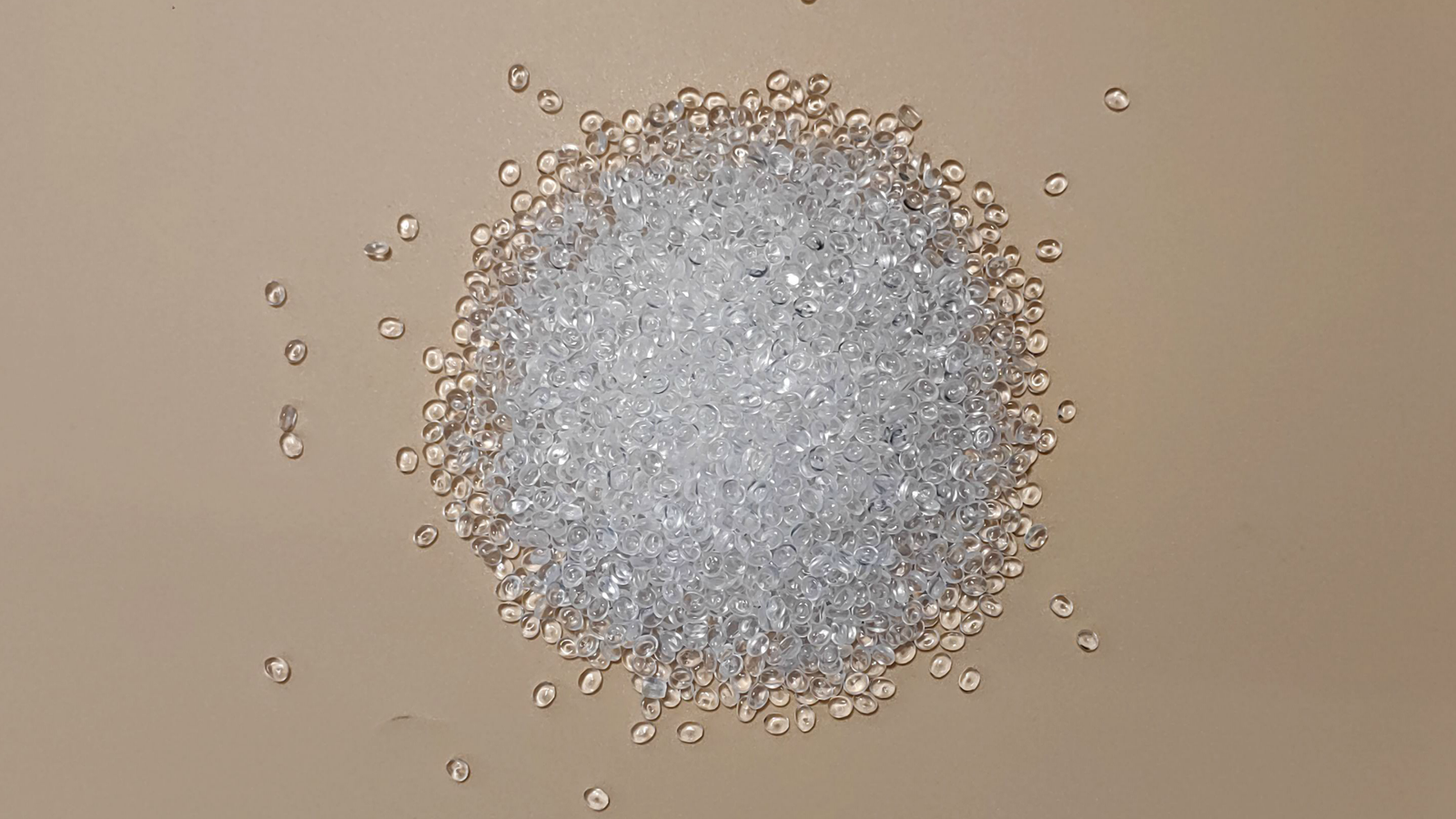

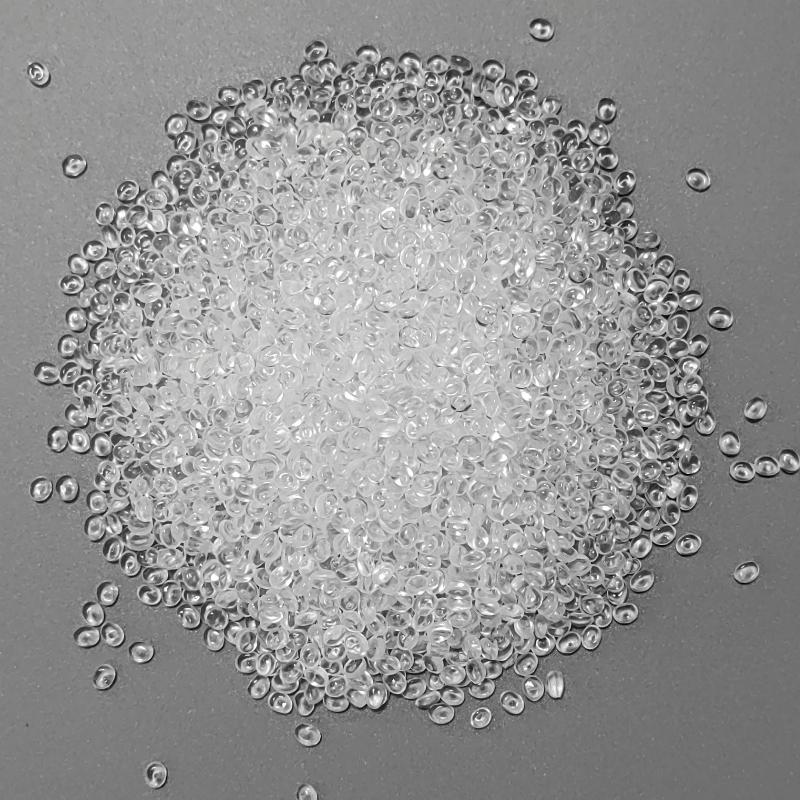

Metallocene Linear Low-Density Polyethylene Display

【Related Recommendations】

mLLDPE D173: High-Clarity, Tough Film-Grade Mlldpe Resin for Packaging Learn more>

Metallocene mLLDPE LL7810A injection molding grade plastic raw material Learn more>

What material is ABS? Learn more>