PRODUCTS

LX04420C (PDX-L-04420 CCS) - Conductive Filled PEEK Material

Product Struction

What is PEEK Material

LNP™ STAT-KON™ LX04420C (PDX-L-04420 CCS) is a conductive peek material (polyetheretherketone) composite material developed by SABIC. This material is modified through proprietary conductive fillers and is specifically designed for high-precision injection molding processes. It combines the heat resistance, mechanical strength and chemical stability of PEEK, and also features stable electrostatic discharge (ESD) performance. It is highly suitable for the manufacturing of electronic, electrical and high-end industrial components.

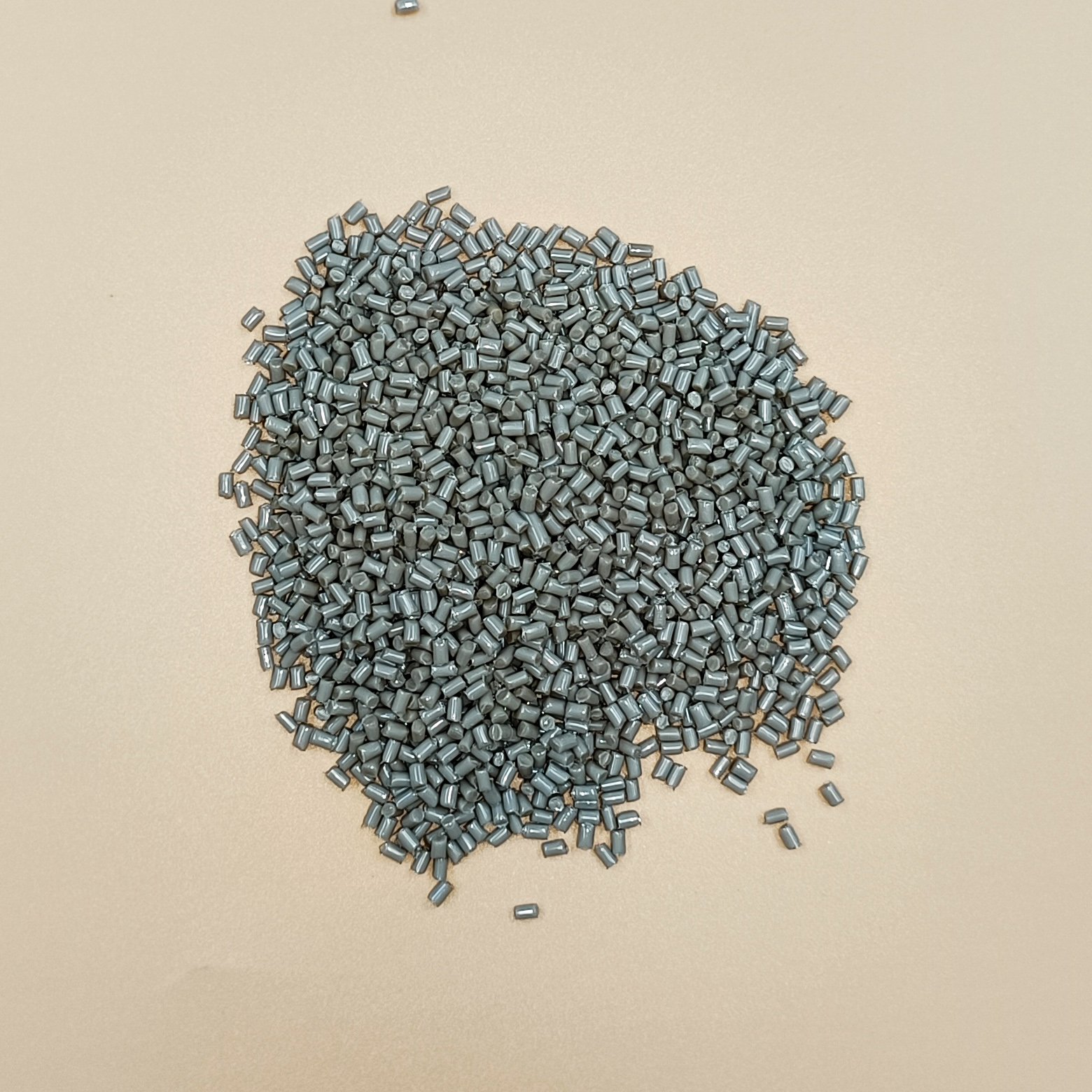

・Product form: Granular

・Colour: Black

・Processing method: Injection molding

・Material properties: Conductive, filling, high cleanliness modified series

01 | Product highlights

Stable electrical conductivity

The surface resistivity is between 10⁶ and 10⁸ Ω, which can achieve stable electrostatic dissipation and prevent damage to electronic components.

Excellent mechanical rigidity

The tensile strength reaches 149 MPa, and the flexural modulus exceeds 10,000 MPa, maintaining structural stability and precision.

Outstanding High-Temperature Performance

The heat distortion temperature can reach up to 300°C (ASTM D648, 1.8 MPa), and it is suitable for high-temperature continuous operating environments.

Excellent dimensional stability

It has a low shrinkage rate (0.3-0.6%) and a linear expansion coefficient of only 3.9×10⁻⁵ cm/cm/°C, making it suitable for high-precision parts.

Clean electrical performance

It meets the safety production requirements of cleanrooms and ESD, and is suitable for the manufacturing of electronic display and semiconductor equipment.

02 | Performance Analysis

LNP™ STAT-KON™ LX04420C adopts a ratio of high-purity peek material substrate and proprietary conductive fillers to ensure the combination of electrical conductivity, heat resistance and structural integrity.

Compared with common conductive engineering plastics, this product has obvious advantages in the following aspects:

・The heat distortion temperature is raised by approximately 50°C, which is superior to that of carbon fiber or carbon black-filled PA, PPS and other materials.

・Low gas emission, more suitable for clean application environments such as semiconductors and displays;

・The electrical conductivity remains stable in thermal cycling and high-humidity environments.

03 | Processing suggestions

・Recommended process: Injection molding

・Drying conditions: 150°C, 3 to 4 hours

・Melting temperature: 360-400°C

・Mold temperature: 170-200°C

Appropriate drying and mold temperature control can ensure the consistency of conductivity and the appearance quality of the product, especially suitable for thin-walled, complex-structured or high-precision ESD components.

For manufacturers using peek material, controlling process parameters is the key to ensuring the stability of product performance.

04 | Typical applications

LNP™ STAT-KON™ LX04420C is widely used in:

・Electronic and semiconductor equipment: wafer trays, conductive fixtures, housing assemblies

・Display and optical equipment: Support structural components with low particle release

・Industrial sensors and connectors: Components that attach equal importance to dimensional accuracy and electrical conductivity

・Automotive electronic modules: ESD protection housing and structural components

The demand for peek material in these fields continues to grow, mainly because it has both mechanical stability and electrical controllability.

05 | PEEK material properties data sheet - PEEK LX04420C (PDX-L-04420 CCS)

| Mechanical behavior | Condition | Standard | Value | Unit | |||

| Instrument Shock | 23℃ Peak Energy | ASTM D3763 | 2 | J | |||

| Elongation | Yield | ASTM D638 | 2.3 | % | |||

| Elongation | Break | ASTM D638 | 2.3 | % | |||

| Elongation | Yield | ISO 527 | 2.1 | % | |||

| Elongation | Break | ISO 527 | 2.1 | % | |||

| Multi-Axial Impact | ISO 6603 | 2 | J | ||||

| Flexural Strength | ASTM D790 | 241 | MPa | ||||

| Flexural Strength | ISO 178 | 241 | MPa | ||||

| Flexural Modulus | ASTM D790 | 10790 | MPa | ||||

| Flexural Modulus | ISO 178 | 10270 | MPa | ||||

| Izod Un-notch Impact | 23℃ | ASTM D4812 | 576 | J/m | |||

| Izod Un-notch Impact | 23℃ 4.00mm | ISO 180 | 212 | kJ/m² | |||

| Izod Notch Impact | 23℃ | ASTM D256 | 48 | J/m | |||

| Izod Notch Impact | 23℃ 4.00mm | ISO 180 | 13 | kJ/m² | |||

| Tensile Strength | Yield | ASTM D638 | 149 | MPa | |||

| Tensile Strength | Break | ASTM D638 | 149 | MPa | |||

| Tensile Strength | Yield | ISO 527 | 149 | MPa | |||

| Tensile Strength | Break | ISO 527 | 149 | MPa | |||

| Tensile Modulus | 50mm/min | ASTM D638 | 11990 | MPa | |||

| Tensile Modulus | 1.0mm/min | ISO 527 | 11500 | MPa | |||

| Thermal | Condition | Standard | Value | Unit | |||

| HDT | Unannealed 1.80MPa 3.20mm | ASTM D648 | 300 | ℃ | |||

| HDT | 1.80MPa 4.00mm | ISO 75 | 246 | ℃ | |||

| CLE | Flow -40.0~40℃ | ASTM E831 | 3.96E-5 | cm/cm/℃ | |||

| CLE | xFlow -40.0~40℃ | ASTM E831 | 1.62E-5 | cm/cm/℃ | |||

| CLE | Flow -40.0~40℃ | ISO 11359 | 4.12E-5 | cm/cm/℃ | |||

| CLE | xFlow -40.0~40℃ | ISO 11359 | 1.63E-5 | cm/cm/℃ | |||

| Physical property | Condition | Standard | Value | Unit | |||

| Shrinkage | Flow 24hr | ASTM D955 | 0.3 | % | |||

| Shrinkage | xFlow 24hr | ASTM D955 | 0.6 | % | |||

| Shrinkage | Flow 24hr | ISO 294 | 0.34 | % | |||

| Shrinkage | xFlow 24hr | ISO 294 | 0.62 | % | |||

| Density | ASTM D792 | 1.36 | g/cm³ | ||||

| Density | ISO 1183 | 1.36 | g/cm³ | ||||

| Electrical properties | Condition | Standard | Value | Unit | |||

| Volume Resistivity | ASTM D257 | 1E6~1E8 | Ω.cm | ||||

| Surface Resistivity | ASTM D257 | 1E6~1E8 | Ω | ||||

06 | Industry trends

With the continuous improvement of global manufacturing requirements for electrostatic discharge protection (ESD) and clean materials, conductive peek material is gradually becoming an important choice in high-end electronics and industrial fields.

LNP™ STAT-KON™ LX04420C, with its outstanding heat resistance, mechanical strength and stable electrical conductivity, offers an ideal solution for the next generation of high-reliability applications.

07 | Similar recommendations (provided by Juyuan)

| Manufacturer | Product Model | Specific Gravity | Tensile Strength | Elongation | Shrinkage | Tensile Modulus | Heat Deflection Temp | Izod Impact (Notched) | Flexural Modulus | Izod Impact (Unnotched) | Coefficient of Linear Expansion | Flexural Strength |

| SABIC | LL004C (LL-4040 CCS) | 1.37 g/cm³ | 74 MPa | 5.80% | 1.30% | 2890 MPa | — | 96 J/m | 2960 MPa | 1548 J/m | — | 117 MPa |

| SABIC | LX00797C (PDX-L-00797 CCS) | 1.39 g/cm³ | 155 MPa | 2.50% | — | — | 310 ℃ | 53 J/m | 7920 MPa | 270 J/m | — | 195 MPa |

| SABIC | LX00486C (PDX-L-00486 CCS) | 1.4 g/cm³ | 179 MPa | 2% | 0.25% | 17280 MPa | 336 ℃ | 63 J/m | 13600 MPa | 657 J/m | 1.1E-5 cm/cm/℃ | 262 MPa |

Selection suggestions

・If high modulus and high heat deflection temperature are pursued, LX00486C is recommended.

・If a balance between strength and formability is required, LX00797C can be chosen.

・If universality and cost-effectiveness are emphasized, LL004C is an ideal choice.

As a professional supplier of peek material, Juyuan can provide differentiated selection support according to customer requirements.

08 | Why choose Juyuan

As a professional supplier with 24 years of international experience in plastic raw material trade, Juyuan provides global customers with:

・Stable supply of original SABIC PEEK series products

・Full-process selection and technical support

・Complete compliance documents (RoHS, REACH, FDA, UL, etc.)

・Fast international logistics and professional after-sales service

Juyuan is committed to helping customers achieve more reliable material performance in the fields of electronics, electrical engineering, industry and medical care, especially having rich supply experience in the field of peek material.

09 | Frequently Asked Questions

Q1: Is LNP™ STAT-KON™ LX04420C suitable for cleanrooms?

Yes, its low precipitation and stable resistance characteristics are highly suitable for clean processes in the semiconductor and display industries.

Q2: Is it recommended to use recycled materials?

It is not recommended to reuse recycled materials in ESD-critical applications to avoid affecting conductivity and surface quality.

Q3: What advantages does it have compared with PPS conductive materials?

PEEK substrates have higher heat resistance, better dimensional stability and superior mechanical properties, making them stand out in the peek material category.

【Related Recommendations】

Extrusion Molding Defects & Solutions | Plastic Resin Supply Learn more>

Radel® R-5600 NT: Transparent Flame-Retardant PPSU Plastic Learn more>

RADEL® R-5800 PPSU: Transparent Heat-Resistant Materials Learn more>