PRODUCTS

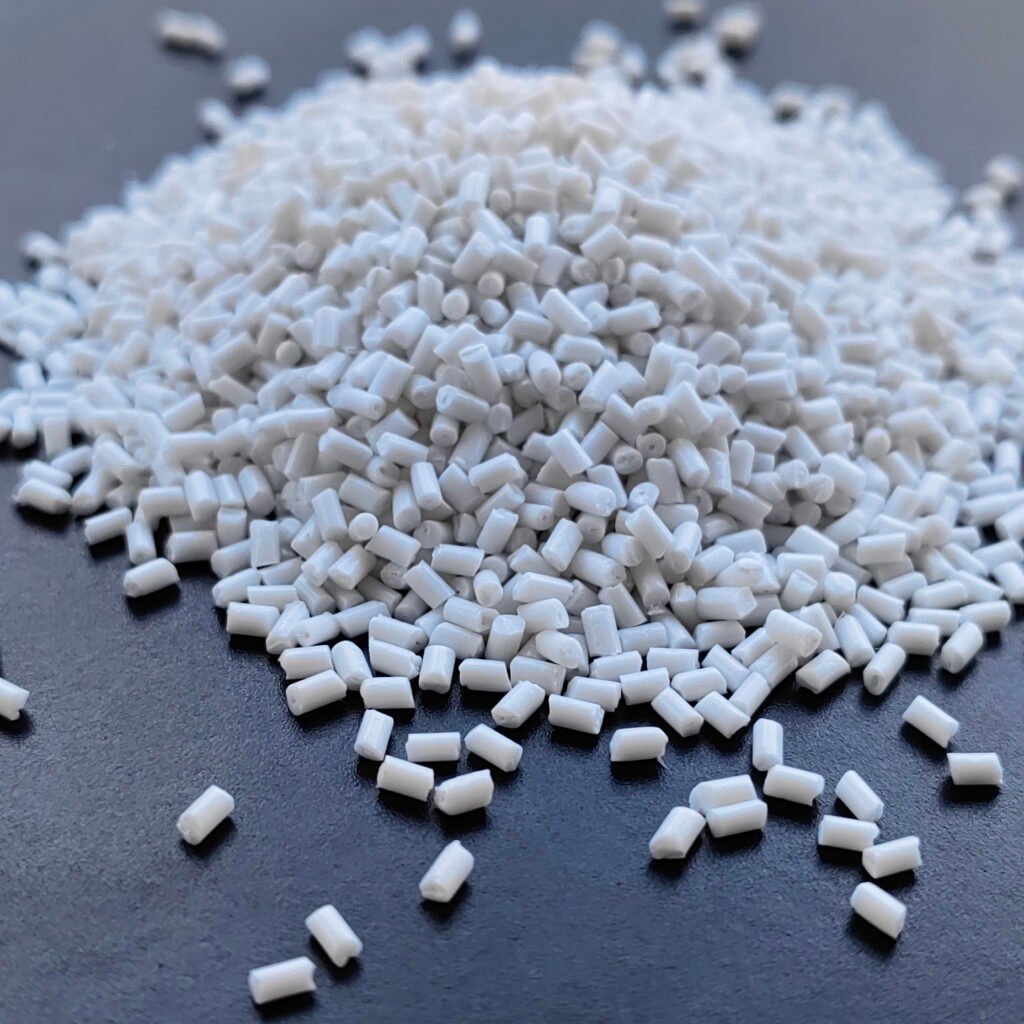

LUCEL POM GB-325 plastic raw material

Product Struction

Polyoxymethylene (POM), also known as acetal or Delrin, is a high-density, high-crystallinity thermoplastic engineering plastic polymerized from formaldehyde and other raw materials. POM materials are divided into homopolymer (POM-H) and copolymer (POM-K), both of which have excellent physical, mechanical, and chemical properties, particularly excelling in friction resistance.

This high-density crystalline polymer, with no side chains, has a smooth and glossy surface, is hard and dense, and typically appears pale yellow or white. POM can be used long-term within the temperature range of -40°C to 100°C, offering superior wear resistance and self-lubrication. Additionally, POM's resistance to oils and peroxides surpasses that of most engineering plastics. By adding ultraviolet stabilizers (UV agents), its UV resistance is significantly enhanced.

Among various grades, POM GB-325 stands out with remarkable performance. At 23°C, its tensile strength is 64 MPa, with static and dynamic friction coefficients of 0.15 and 0.21, respectively, and an elongation rate of 10%. This material performs excellently in the Taber wear test, with a wear rate of only 22 mg per 1000 cycles. At the same temperature, POM GB-325 has a flexural modulus of 3900 MPa, flexural strength of 98 MPa, and a notched Izod impact strength of 35.71 kJ/m². Additionally, its heat deflection temperature, in the non-annealed state, is 165°C under 0.45 MPa and 150°C under 1.8 MPa, with a specific gravity of 1.59 g/cm³. The shrinkage rate in the flow direction and perpendicular direction is 1.6% and 1.9%, respectively, and it has a Rockwell hardness of M scale 80.

These excellent properties make POM GB-325 perform exceptionally well in applications requiring high strength and wear resistance, such as gears, bearings, pulleys, and various mechanical parts. POM's superior characteristics ensure its wide use in the industry and demonstrate its unique advantages in various everyday applications.

| Mechanical behavior | Condition | Standard | Value | Unit | |||

| Tensile Strength | Break 23°C | ASTM D638 | 64 | MPa | |||

| Friction Coefficient | Static | ASTM D3702 | 0.15 | ||||

| Friction Coefficient | Dynamic | ASTM D3702 | 0.21 | ||||

| Elongation | 23°C | ASTM D638 | 10 | % | |||

| Tiber wear and tear | ASTM D1044 | 22 | mg/1000cy | ||||

| Flexural Modulus | 23°C | ASTM D790 | 3900 | MPa | |||

| Flexural Strength | 23°C | ASTM D790 | 98 | MPa | |||

| Izod Notch Impact | ASTM D256 | 35.71 | kJ/m² | ||||

| Izod Notch Impact | 23°C | ASTM D256 | 4.08 | kJ/m² | |||

| Thermal | Condition | Standard | Value | Unit | |||

| HDT | Unannealed 0.45MPa | ASTM D648 | 165 | °C | |||

| HDT | Unannealed 1.8MPa | ASTM D648 | 150 | °C | |||

| Physical property | Condition | Standard | Value | Unit | |||

| Density | ASTM D792 | 1.59 | g/cm³ | ||||

| Shrinkage | Flow | ASTM D995 | 1.6 | % | |||

| Shrinkage | xFlow | ASTM D995 | 1.9 | % | |||

| Hardness | Condition | Standard | Value | Unit | |||

| Rockwell Hardness | M(Scale) | ASTM D785 | 80 | ||||