PRODUCTS

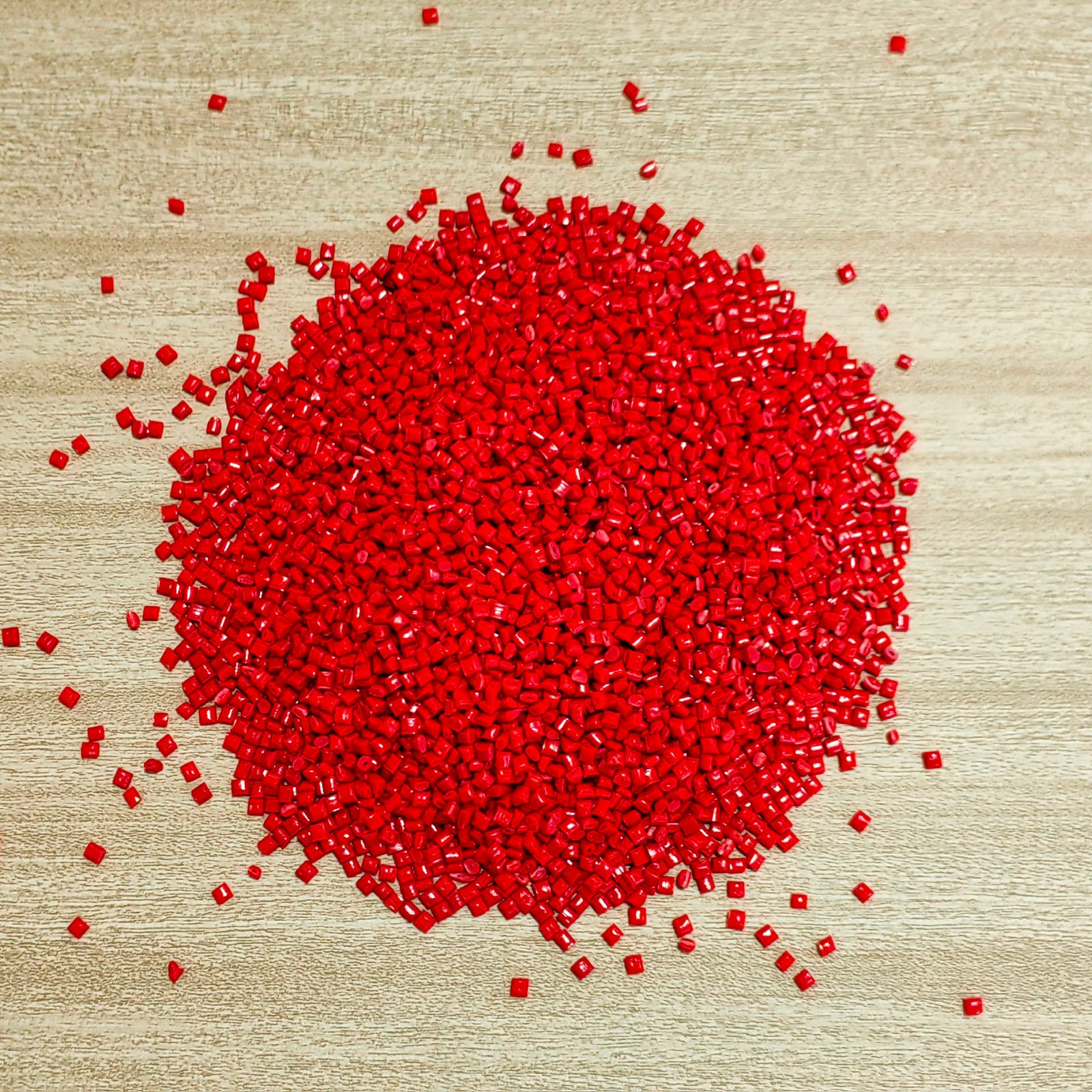

LNP™ THERMOCOMP™ 9X10401H Filled PPSU for Medical

Product Struction

What is LNP™ THERMOCOMP™

LNP™ THERMOCOMP™ 9X10401H is a filled PPSU (polyphenylsulfone) material, specifically designed to provide long-term mechanical stability and chemical resistance in demanding environments. This material features excellent heat resistance and dimensional stability, making it suitable for outdoor applications, electronic and electrical appliances, automotive parts, construction, and medical care fields. With its unique filling and modification formula, 9X10401H achieves a balanced performance in impact toughness and structural strength, meeting the demanding requirements of a wide range of industrial and consumer products.

01 | Material highlights and characteristics

Heat resistance and dimensional stability: The high heat distortion temperature ensures that the material is not prone to deformation in high-temperature environments, making it suitable for complex structural components.

Enhance mechanical properties: Through filling modification, the flexural modulus and tensile strength are optimized, ensuring the product remains stable under long-term stress scenarios.

Low water absorption rate: Excellent moisture-proof properties ensure the reliability of electronic and electrical appliances as well as liquid handling applications.

Multi-scenario adaptability: It caters to outdoor, industrial and home applications, offering diverse possibilities for material usage.

Processability: Suitable for injection molding and precision forming processes, it can achieve high-precision parts with complex geometric structures.

02 | Main application fields

Outdoor applications: Lawn equipment, garden tools, lighting enclosures and other components that are exposed to the environment for a long time.

Electronic and electrical appliances: display housings, electrical connectors and liquid handling components.

Automotive industry: Engine hoods, interior structural components, functional accessories.

Building and household goods: Door and window accessories, bathroom fixtures and durable household parts.

Medical and nursing: It can be used for non-implantable medical devices and nursing products resistant to chemical cleaning.

Oil and gas: Industrial components resistant to high temperatures and high stress environments.

03 | LNP™ THERMOCOMP™ 9X10401H Data Sheet

| Mechanical behavior | Condition | Standard | Value | Unit | |||

| Instrument shock | 23℃ Total energy | ASTM D3763 | 34 | J | |||

| Elongation | Yield 5mm/min | ASTM D638 | 7 | % | |||

| Elongation | Break 5mm/min | ASTM D638 | 12 | % | |||

| Elongation | Yield 5mm/min | ISO 527 | 7 | % | |||

| Elongation | Break 5mm/min | ISO 527 | 12 | % | |||

| Multi-axial impact | ISO 6603 | 29 | J | ||||

| Flexural Strength | ISO 178 | 0.0 | MPa | ||||

| Flexural Modulus | 1.3mm/min | ASTM D790 | 2720 | MPa | |||

| Flexural Modulus | 2.0mm/min | ISO 178 | 2570 | MPa | |||

| Izod Un-notch Impact | 23℃ | ASTM D4812 | 1640 | J/m | |||

| Izod Un-notch Impact | 23℃ 4.00mm | ISO 180 | 175 | kJ/m² | |||

| Izod Notch Impact | 23℃ | ASTM D256 | 86 | J/m | |||

| Izod Notch Impact | 23℃ 4.00mm | ISO 180 | 8 | kJ/m² | |||

| Tensile Strength | Yield 5mm/min | ASTM D638 | 72 | MPa | |||

| Tensile Strength | Break 5mm/min | ASTM D638 | 57 | MPa | |||

| Tensile Strength | Yield 5mm/min | ISO 527 | 71 | MPa | |||

| Tensile Strength | Break 5mm/min | ISO 527 | 57 | MPa | |||

| Tensile Modulus | 5mm/min | ASTM D638 | 2660 | MPa | |||

| Tensile Modulus | 1.0mm/min | ISO 527 | 2550 | MPa | |||

| Thermal | Condition | Standard | Value | Unit | |||

| HDT | Unannealed 0.45MPa 3.20mm | ASTM D648 | 214 | ℃ | |||

| HDT | Unannealed 1.80MPa 3.20mm | ASTM D648 | 203 | ℃ | |||

| HDT | 0.45MPa 4.00mm | ISO 75 | 213 | ℃ | |||

| HDT | 1.80MPa 4.00mm | ISO 75 | 200 | ℃ | |||

| CLE | Flow -30.0~30℃ | ASTM D696 | 5.3E-5 | cm/cm/℃ | |||

| CLE | xFlow -30.0~30℃ | ASTM D696 | 5.3E-5 | cm/cm/℃ | |||

| Physical property | Condition | Standard | Value | Unit | |||

| Water Absorption | 50RH 24hr | ASTM D570 | 0.26 | % | |||

| Water Absorption | 23℃ 50RH | ISO 62 | 0.47 | % | |||

| Shrinkage | Flow 24hr | ASTM D955 | 0.8~1 | % | |||

| Shrinkage | xFlow 24hr | ASTM D955 | 1~3 | % | |||

| Density | ASTM D792 | 1.46 | g/cm³ | ||||

| Density | ASTM D792 | 1.45 | g/cm³ | ||||

04 | Technology and processing techniques

The LNP™ THERMOCOMP™ 9X10401H can be processed by conventional injection molding techniques and is also suitable for manufacturing complex components in multi-axial stress scenarios. Its filled and modified structure can maintain fluidity and dimensional accuracy during the injection molding process, providing a reliable guarantee for large-sized and highly complex parts. For customers, rationally optimizing the mold design and cooling system can further enhance the performance of parts and production efficiency.

05 | Innovation and industry competitive advantage

Filling modification technology: Achieving a balance between high strength and rigidity through directional filling while maintaining the material's processability.

Comprehensive performance optimization: Taking into account thermal performance, mechanical performance and chemical resistance, the material demonstrates stability and reliability in multiple application scenarios.

Wide application: From automotive engine hoods to electronic display casings, it can replace various engineering plastics in multiple scenarios, reducing the complexity of material procurement.

Environmental protection and Sustainability: Complies with international plastic industry standards and meets the requirements of future industrial and construction environmental protection regulations.

06 | Customer feedback

Feedback from multiple overseas customers in the fields of automobiles, electronics and industrial equipment:

・Automobile parts manufacturer: The engine hood made of 9X10401H shows no obvious deformation in a long-term high-temperature environment.

・Electronic housing supplier: The housing components perform stably in outdoor exposure tests, have a low water absorption rate and no surface warping.

・Industrial equipment company: In liquid handling and petroleum environments, the material has outstanding chemical resistance and an extended maintenance cycle.

07 | FAQ

Q1: Is the 9X10401H suitable for outdoor high-temperature environments?

A: Yes, its high heat distortion temperature and low water absorption rate enable it to maintain dimensional stability even in high-temperature and humid environments.

Q2: Which processing techniques are suitable?

A: It is mainly injection molding process, and complex parts can also be manufactured through precision compression molding.

Q3: What are the advantages over unfilled PPSU?

A: Filled materials have higher flexural modulus and tensile strength, while maintaining good impact toughness and dimensional stability, making them suitable for load-bearing structural components.

08 | Similar recommendations

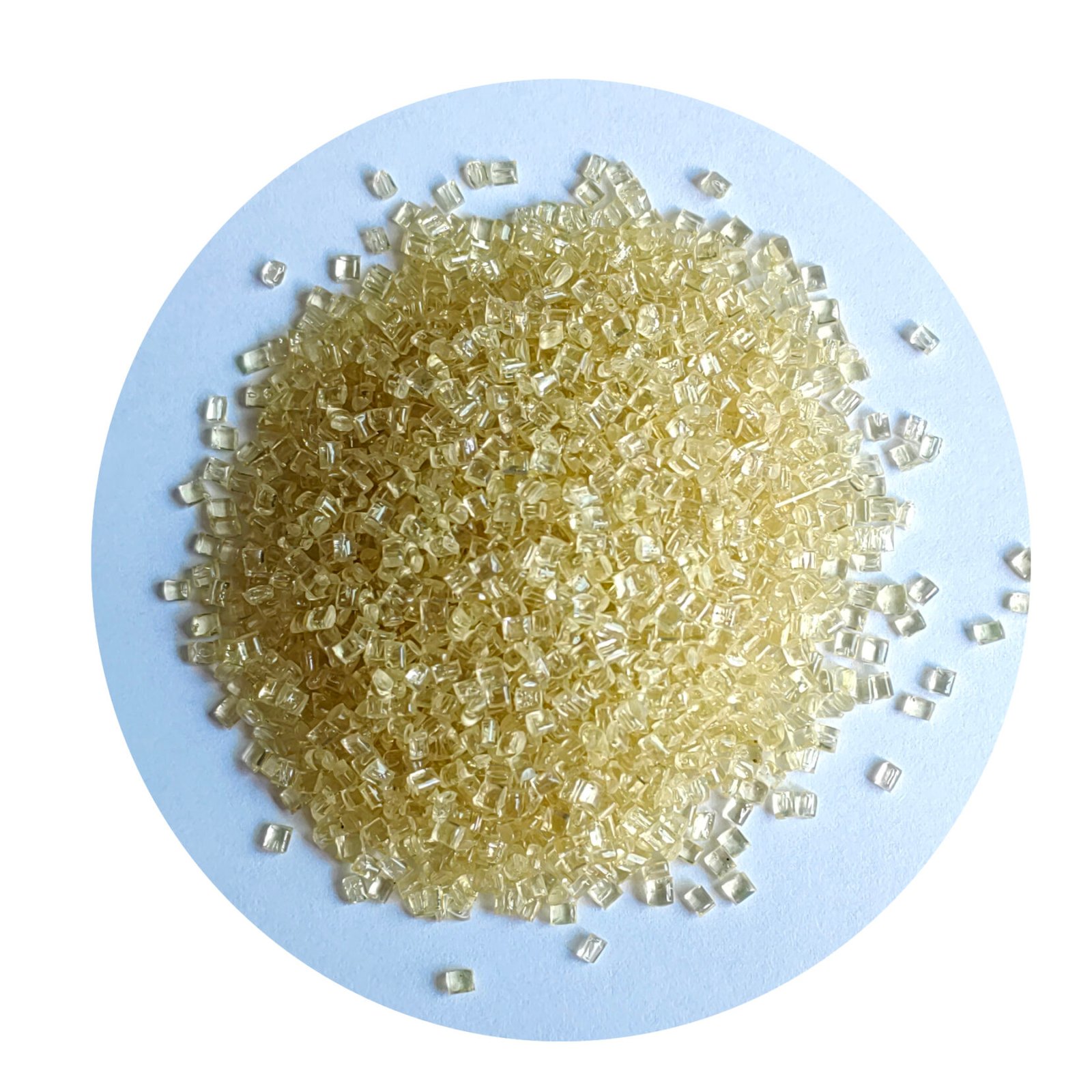

・LNP™ THERMOCOMP™ 9X04488 (PDX-04488) : Suitable for processing parts with high toughness requirements, it performs particularly well in the fields of durable parts for electronics, electrical appliances and home appliances.

09 | Juyuan foreign trade supply advantages

As an international plastic raw material trader, Juyuan can provide customers with:

・A stable global supply chain ensures the timely delivery of materials.

・Comprehensive technical support to assist customers in material selection and process optimization.

・Multi-batch testing and quality assurance reduce production risks.

・Customized logistics solutions, covering major markets in Asia, Europe, America, etc.

【Related Recommendations】

Mitsubishi Sultron™ PPSU LSG: High-Heat, Flame-Retardant Medical R5500/XL Learn more>

HiFill® PPSU Series: Tailored Plastics for Demanding Applications Learn more>

RADEL R5500 vs R4400: PPSU Selection & Comparison Guide Learn more>