PRODUCTS

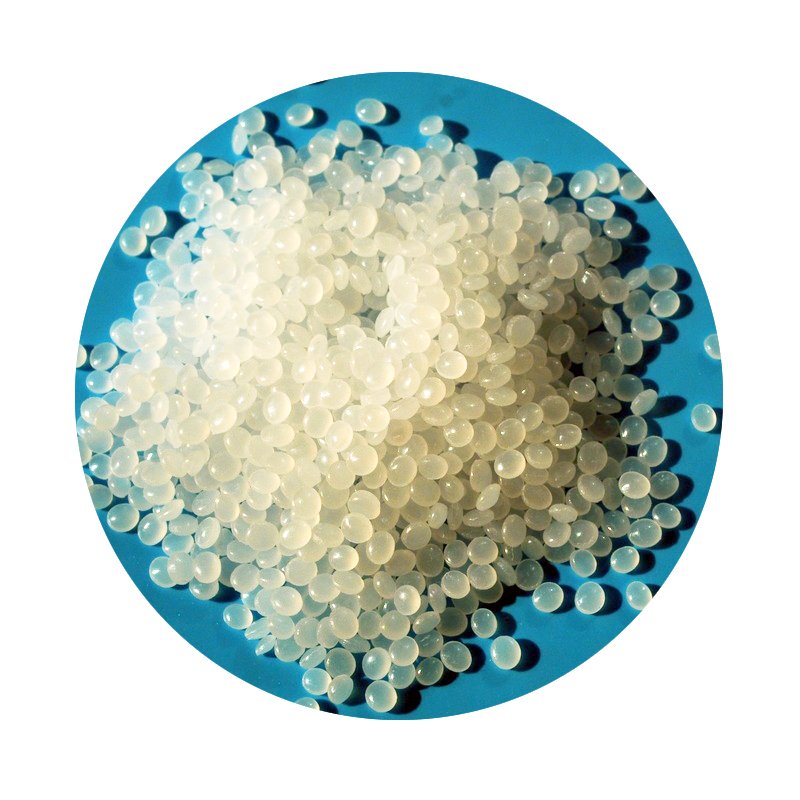

LLDPE LL0209AA Overview | LLDPE Resin Properties and TDS

Product Struction

What is LLDPE Resin - LL0209AA

At a time when the packaging industry is constantly pursuing lightweight and high strength, LLDPE LL0209AA has become an ideal choice for many blown film and composite film manufacturers with its excellent mechanical properties and good processability. This linear low-density polyethylene (LLDPE resin) developed by AKPC uses a butene comonomer design to enhance tear and impact resistance while maintaining the flexibility of the material. It is especially suitable for heavy packaging films, agricultural films, and wrapping films that have strict requirements on mechanical strength.

01 | Highlights of LLDPE resin: Stronger ductility and higher damage resistance

Ultra-high elongation at break: Up to 840% in the vertical direction, ensuring that the film is not easy to break during stretching and has excellent flexibility.

Good tear resistance: The tear strength in the flow direction is 145 g/25μm, and the vertical direction is as high as 370 g/25μm, which is suitable for applications that require high wear resistance.

Drop hammer impact strength reaches 130g: Resist puncture impact during transportation and stacking, and extend the service life of packaging.

Melt index is only 0.9 g/10min: moderate fluidity, easy to accurately control film thickness, and improve the operating stability of film blowing equipment.

Add antioxidants and calcium soap stabilizers: enhance thermal stability and durability during processing.

02 | Application areas: from agricultural films to heavy bags, adapting to a variety of needs

Heavy packaging bags & lining films: tear and puncture resistance are suitable for loading high-weight items such as building materials and fertilizers.

Wrap film & shrink film: good ductility, can adapt to the packaging needs of goods of different shapes, and improve transportation safety.

Agricultural film products: still maintain toughness under ultraviolet rays and wind and sand, reducing the frequency of replacement.

Composite film substrate: can be compounded with a variety of materials (such as PA, EVOH, etc.) to manufacture functional packaging films with barrier properties and mechanical strength.

03 | Technical Data Overview of LLDPE LL0209AA Resin

| Mechanical behavior | Condition | Standard | Value | Unit | |||

| Elongation | Flow Break | ISO 527 | 620 | % | |||

| Elongation | xFlow Break | ISO 527 | 840 | % | |||

| Tensile Strength | Flow Break | ISO 527 | 41 | MPa | |||

| Tensile Strength | Flow Yield | ISO 527 | 10 | MPa | |||

| Tensile Strength | xFlow Break | ISO 527 | 32 | MPa | |||

| Tensile Strength | xFlow Yield | ISO 527 | 11 | MPa | |||

| Tearing Strength | Flow | ASTM D1922 | 145 | g/25μm | |||

| Tearing Strength | xFlow | ASTM D1922 | 370 | g/25μm | |||

| Falling Weight Impact Strength | ASTM D1709 | 130 | g | ||||

| Physical property | Condition | Standard | Value | Unit | |||

| Density | ISO 1183 | 0.920 | g/cm³ | ||||

| Melt Index | 190°C 2.16kg | ISO 1133 | 0.9 | g/10min | |||

04 | Why Choose AKPC LLDPE LL0209AA?

| Advantage | Description |

|---|---|

| Material Design | Butene copolymer structure ensures a balance of flexibility and strength |

| Food-Related Use | Suitable for non-specific food contact applications |

| Sustainability | Contains heat stabilizers to extend product life and reduce material waste |

| Versatile Compatibility | Applicable to both monolayer and multilayer co-extrusion film structures |

05 | Consult now to obtain samples and technical information!

As a professional plastic raw material supplier, we not only provide a stable supply of LLDPE LL0209AA, but also provide a full set of technical support and flexible ordering solutions. Whether you are developing new functional films or looking for more cost-effective alternatives, we can tailor solutions for you.

Contact us now to get free samples, TDS technical data sheets and application suggestions to upgrade your packaging solutions!

【Related Recommendations】

LLDPE 3470: Reliable Food-Grade Linear Low Density Polyethylene for Injection Molding Learn more>

LLDPE LL 6201XR Resin :Toughness & Processability for Composite Applications Learn more>

Formosa Plastics LLDPE 3224:High-Strength Food Contact Grade Film Plastic Learn more>