PRODUCTS

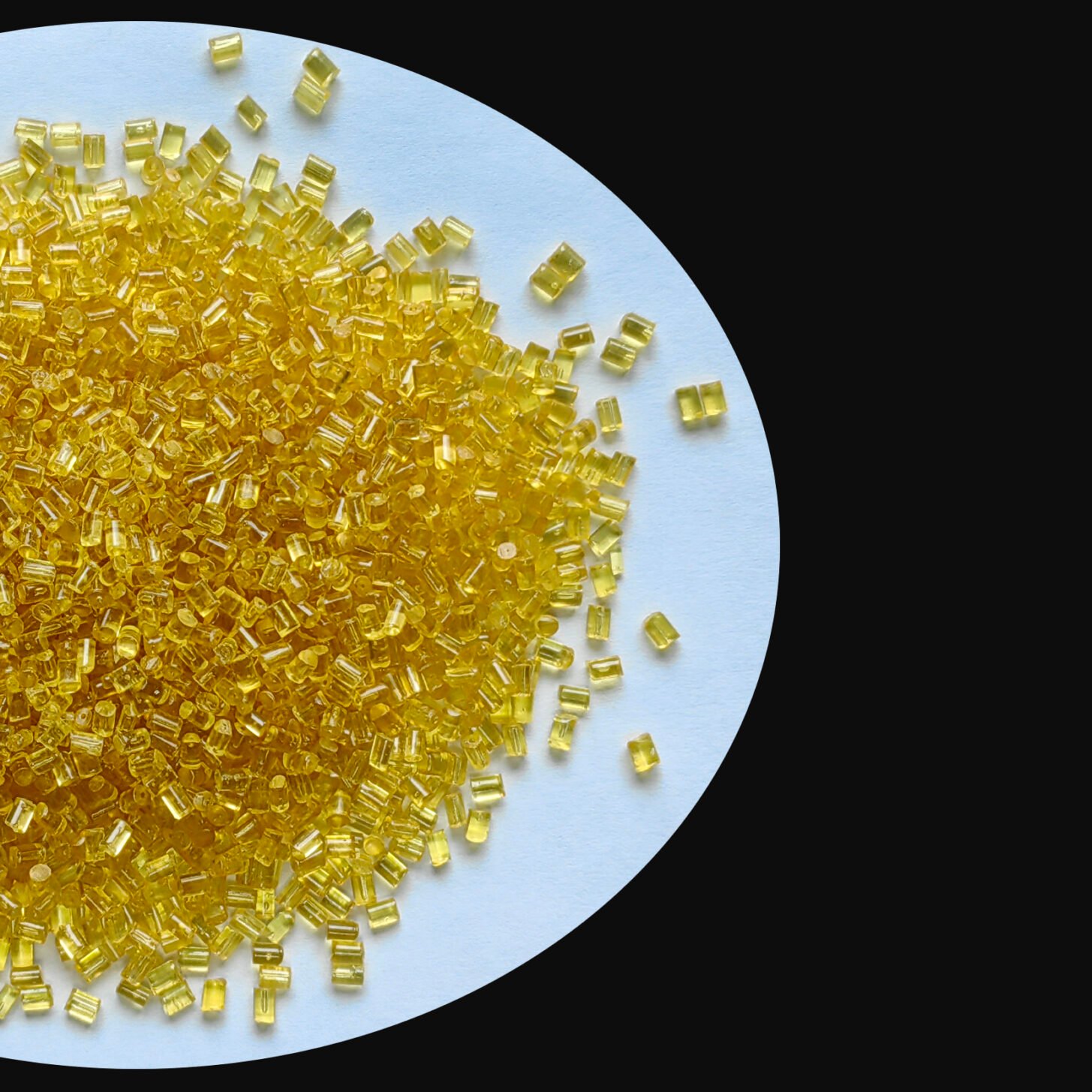

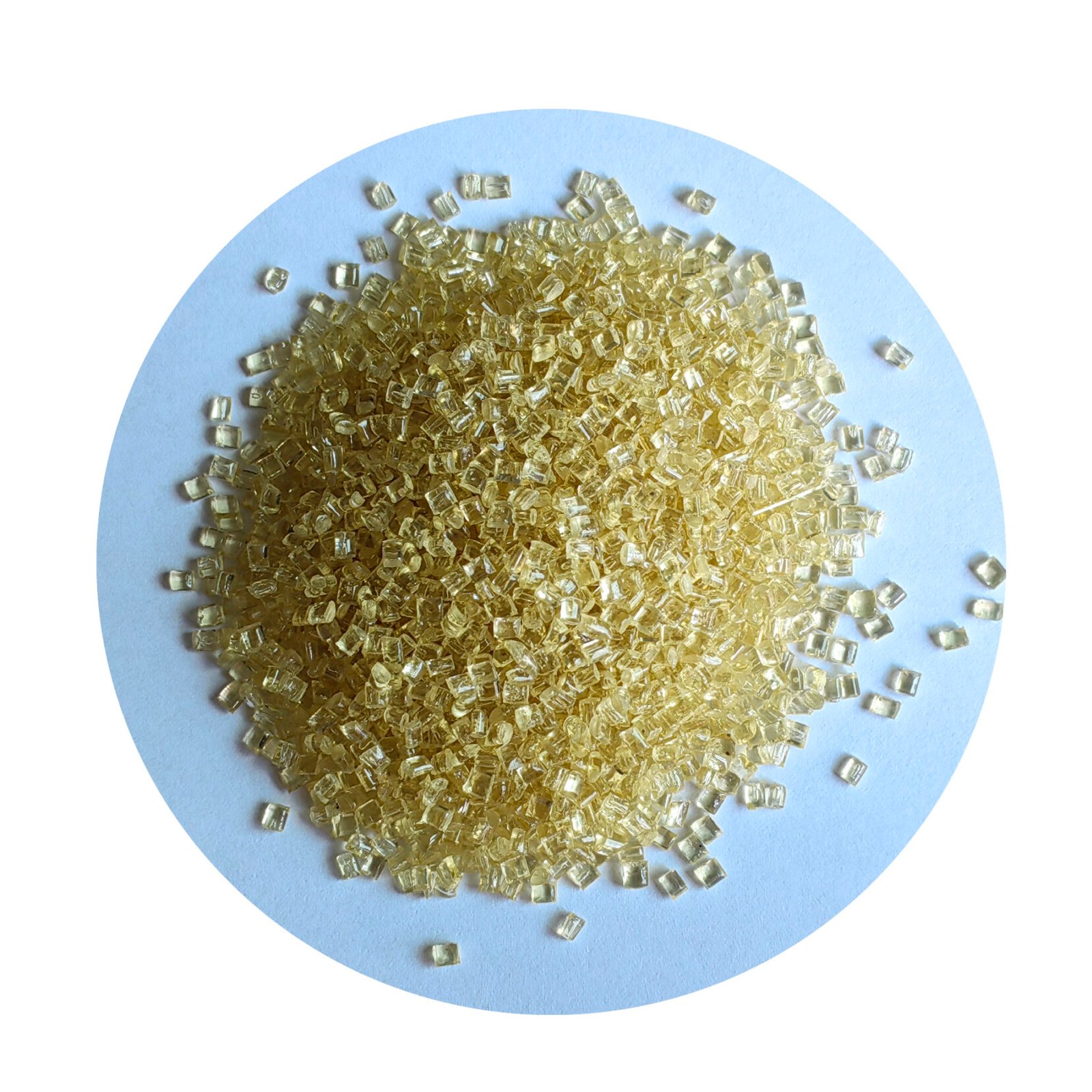

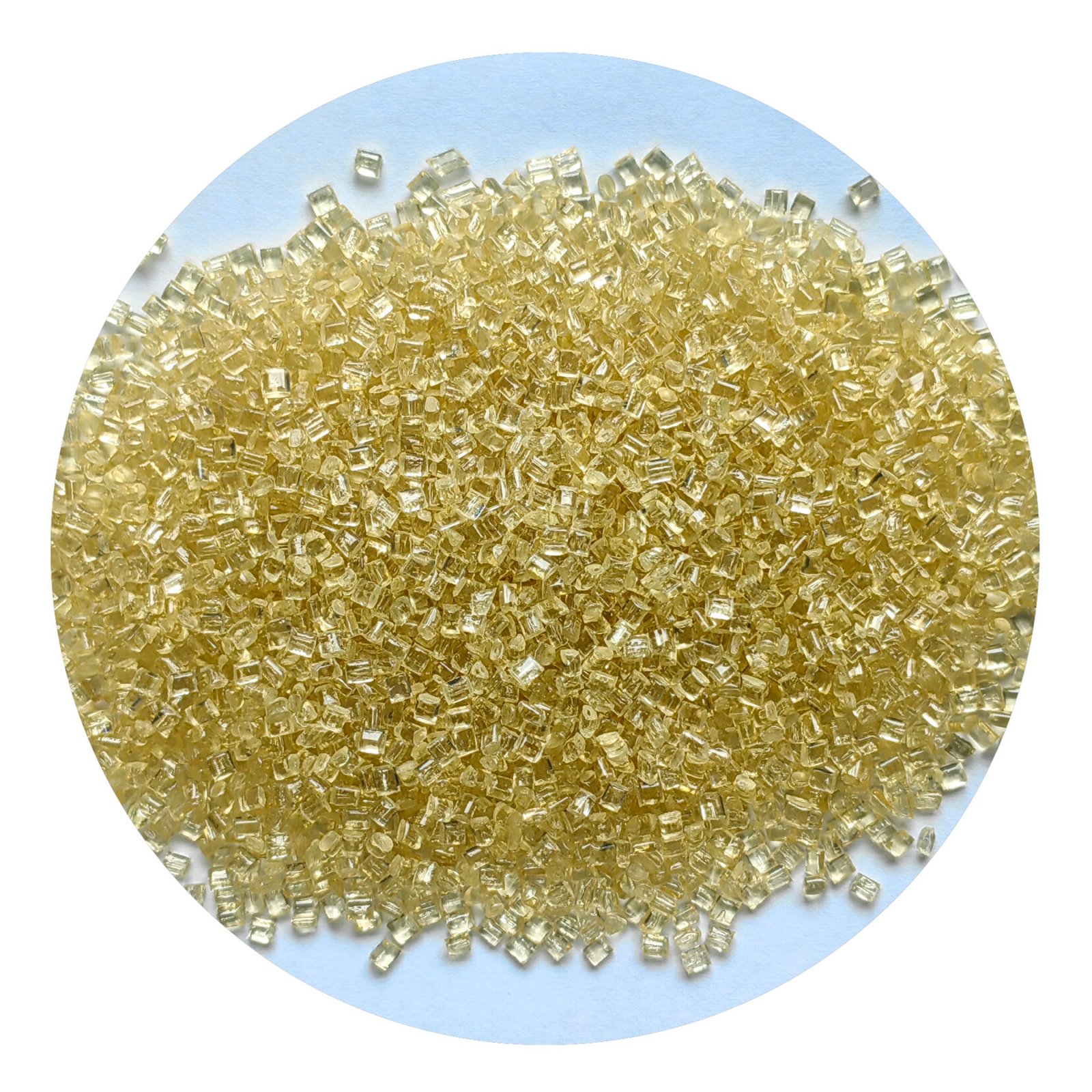

LASULF G/20 | Stable & Low Smoke Polysulfone Plastic

Product Struction

What is LASULF G/20

LASULF G/20 is a glass fiber reinforced polysulfone plastic filled with 20% glass fiber, and its flame retardant grade can reach V-0. Compared with ordinary polysulfone, it maintains excellent heat resistance and electrical insulation performance while significantly enhancing mechanical strength and dimensional stability, making it highly suitable for applications with high temperatures, high loads, and strict safety requirements.

01 | Core Features

High strength and flame retardancy: The glass fiber filling enhances the material's rigidity and impact resistance, while meeting both V-1 and V-0 flame retardant standards.

Heat resistance and dimensional stability: The heat distortion temperature can reach 185℃, and the long-term service temperature can reach 160℃. The products are not prone to warping or deformation.

Reliable electrical performance: The insulation strength can reach 19 KV/mm, with excellent surface resistance and volume resistance, making it suitable for electronic and electrical applications.

Low smoke and low toxicity: The smoke and toxicity produced during the flame retardant process are relatively low, which better meets safety and environmental protection requirements.

Chemical resistance: It can resist common acids, alkalis and some organic media, ensuring long-term stability.

Disinfection resistance: It can withstand high-pressure sterilization and repeated thermal disinfection, making it suitable for medical and laboratory use.

02 | Typical Applications

Electrical and electronic components: switches, coil bobbings and electronic parts, which need to take into account both flame retardancy and insulation performance.

Automotive electronics: Precision components used in high-temperature environments such as sensor housings and electronic control parts.

Industrial equipment: Valves, pump bodies, pipeline fittings, stable for a long time in chemical and high-temperature environments.

Household appliances: microwave oven accessories, heater casings and other high-temperature working parts.

Medical and laboratory equipment: Medical device parts that can be repeatedly sterilized by steam or heat.

03 | Polysulfone Plastic LASULF G/20 Data Sheet

| Mechanical behavior | Condition | Standard | Value | Unit | |||

| Elongation | Break 23℃ 5mm/min | ISO 527 | 2.2 | % | |||

| Tensile Strength | Break 150℃ 5mm/min | ISO 527 | 55 | MPa | |||

| Tensile Modulus | 23℃ 1.0mm/min | ISO 527 | 6500 | MPa | |||

| Tensile Modulus | 150℃ 1.0mm/min | ISO 527 | 5200 | MPa | |||

| Charpy Un-notch Impact | 23℃ | ISO 179 | 30.0 | kJ/m² | |||

| Charpy Notch Impact | 23℃ | ISO 179 | 8.0 | kJ/m² | |||

| Thermal | Condition | Standard | Value | Unit | |||

| HDT | 0.45MPa | ISO 75 | 185 | ℃ | |||

| HDT | 1.80MPa | ISO 75 | 180 | ℃ | |||

| CLE | Flow 30~100℃ | ISO 11359 | 2.5E1 | μm/m/℃ | |||

| Vicat Softening Temperature | 50℃/hr 50N | ISO 306 | 185 | ℃ | |||

| Physical property | Condition | Standard | Value | Unit | |||

| Water Absorption | 24hr | ISO 62 | 0.07 | % | |||

| Shrinkage | Flow 2.00mm 60MPa | ISO 294 | 0.15~0.35 | % | |||

| Shrinkage | xFlow 2.00mm 60MPa | ISO 294 | 0.60~0.80 | % | |||

| Density | ISO 1183 | 1.38 | g/cm³ | ||||

| Electrical properties | Condition | Standard | Value | Unit | |||

| CTI | Solution A | IEC 60112 | 125 | V | |||

| Dielectric Strength | 2.00mm | ASTM D149 | 19 | KV/mm | |||

| Surface Resistivity | ASTM D257 | 1E12 | Ω | ||||

| Flammability | Condition | Standard | Value | Unit | |||

| Limiting Oxygen Index | ASTM D2863 | 38 | % | ||||

| GWFI | 1mm | IEC 60695 | 960 | ℃ | |||

| GWFI | 2mm | IEC 60695 | 960 | ℃ | |||

| Flame Rating | UL94 | V-0 | |||||

| Flame Rating | UL94 | V-1 | |||||

04 | Advantages in Processing and Design

Processing method: Injection molding performs well and can be used to produce components with complex structures.

High structural accuracy: Glass fiber reinforcement reduces warpage and deformation, making it suitable for precision parts.

Flame retardant and controllable: V-1 or V-0 can be achieved at different thicknesses, flexibly meeting various safety requirements.

05 | Industry Trends

Replace traditional materials: Lighter and easier to process than metals and thermosetting plastics.

Regulatory compliance drive: The demand for high-performance flame-retardant materials is on the rise in electronic, automotive and industrial applications.

Sustainable development: High-temperature resistance and chemical resistance extend the service life of products and reduce the frequency of maintenance and replacement.

06 | Similar recommendations

| Manufacturer | Product Model | Specific Gravity | Tensile Strength | Elongation | Shrinkage | Tensile Modulus | Heat Distortion Temp | Vicat Softening Temp |

| Latic | G/15 (LASULF) | 1.34 g/cm³ | 90 MPa | 2.30% | 0.20% | 5500 MPa | 185 ℃ | 185 ℃ |

| Latic | LASULF | 1.23 g/cm³ | 70 MPa | 6% | 0.75% | 2500 MPa | 180 ℃ | 175 ℃ |

| Latic | G/30 (LASULF) | 1.47 g/cm³ | 135 MPa | 2.70% | 0.10% | 8000 MPa | 190 ℃ | 185 ℃ |

07 | FAQ

Q1: Can LASULF G/20 withstand high temperatures for a long time?

A1: It can be used for a long time at 160℃, and the heat distortion temperature is 185℃.

Q2: What are the differences from a regular PSU?

A2:20% glass fiber reinforcement offers higher rigidity, dimensional stability and flame retardancy.

Q3: Is it suitable for repeated disinfection?

A3: The material is resistant to steam sterilization and thermal disinfection, making it highly suitable for medical and laboratory environments.

Q4: Can it be used for drinking water or food contact?

A4: LASULF G/20 is mainly used for industrial, electronic and medical components. For food or drinking water contact, the corresponding certification standards should be referred to.

08 | Why Choose Juyuan?

Juyuan has 24 years of international experience in plastic raw material trade and can provide customers with:

・Stable supply of engineering plastics such as LASULF G/20

・Professional material selection suggestions and application solutions

・Global delivery and flexible response

・Industry trend analysis and case sharing

Choosing Juyuan means not only getting high-quality materials, but also receiving professional services covering material selection, procurement and application.

【Related Recommendations】

QUADRANT® PSU unfilled | Heat Resistant PSU Polysulfone Learn more>

Udel® GF-120 NT Glass-Fiber Reinforced Polysulfone for Medical Learn more>

5G Telecommunication Plastics Selection and Procurement Guide | Juyuan Learn more>