PRODUCTS

LANXESS Material PA6 B30S 000000 Full Guide | Uses & TDS

Product Struction

What is Material PA6

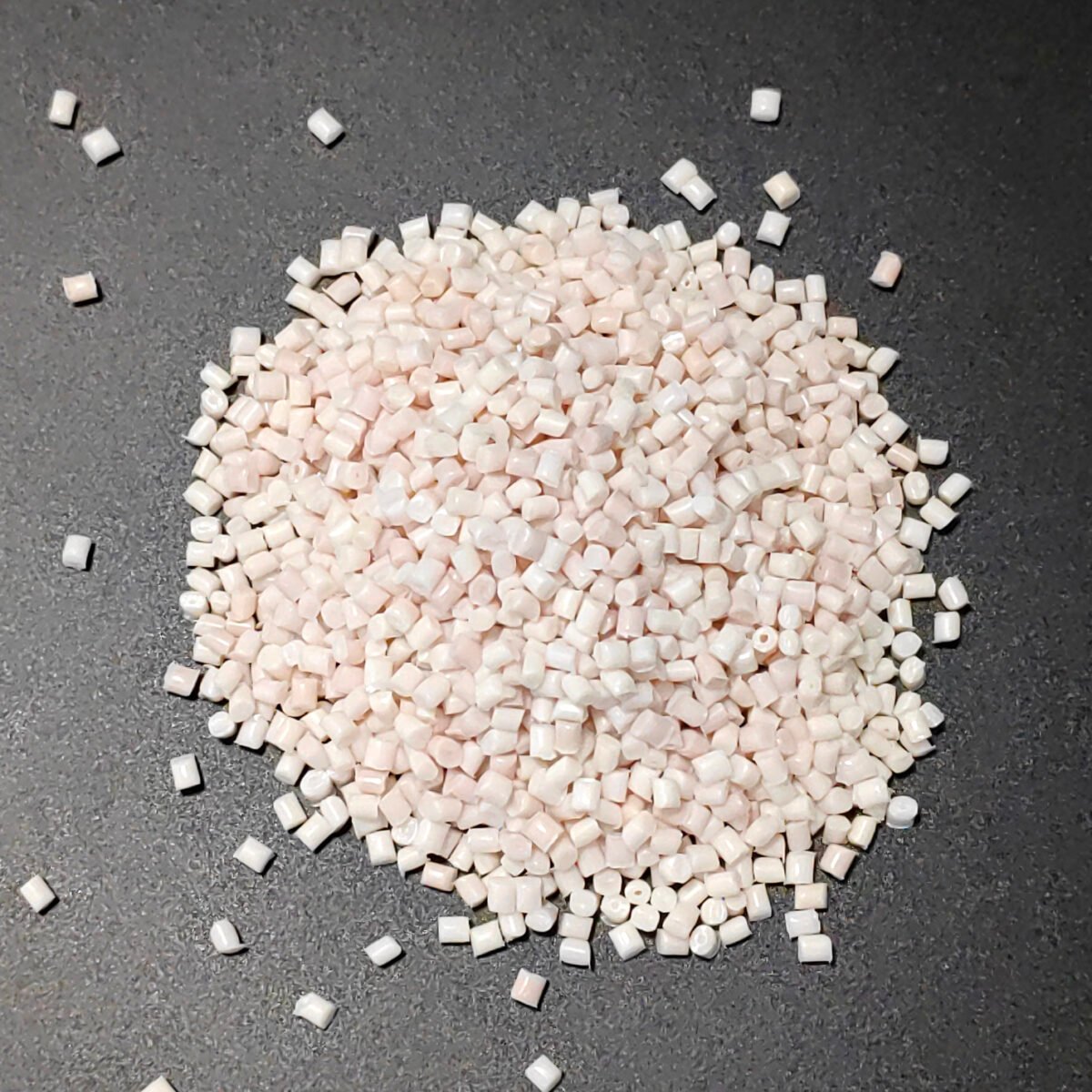

PA6 B30S 000000 is a non-reinforced material PA6 from LANXESS in a granular form suitable for a wide range of injection moulding applications. With the advantages of external lubrication, self-releasing and short cycle time, the material is widely used in automotive, electrical and electronic appliances, household products, sports equipment and other fields. Its flame retardant rating reaches UL94 V-2, which provides a basic guarantee for product safety.

01 | Material PA6 characteristics and processing advantages

Easy mould release treatment: add high efficient release agent, effectively shorten the moulding cycle, improve production efficiency

External lubrication design: enhance the mould filling fluidity, improve the surface quality of the parts

Non-reinforced system: suitable for toughness, lightweight requirements of the injection moulded parts

Good dimensional stability: in the premise of no fibre reinforcing, but still maintains a stable dimensional performance

These characteristics make PA6 B30S 000000 is the ideal material PA6 for applications requiring medium strength and good processability, especially for injection moulded parts with complex structures or high surface quality requirements.

02 | Diversified application coverage

The material is widely used in:

Automotive and transport: interior trim, handles, fixing clips

Electrical and electronics: plastic housings, socket brackets, small electrical components

Consumer goods: toy parts, pram components, stationery, clothing accessories

Sports equipment and outdoor applications: sports protective gear, home fitness equipment

Home appliances and office: printer housings, panel brackets, switches and buttons

With its excellent processing ease and basic physical properties, PA6 B30S 000000 is the material PA6 favoured by many manufacturers.

03 | Suggested parameters for injection moulding

The following parameters are recommended to ensure that the parts are moulded in accordance with the material properties:

Drying conditions: 80°C for 4 hours to prevent the material from absorbing humidity

Melt temperature: 230-260°C, fine adjustment recommended depending on the thickness of the product

Mould temperature: 60-90°C, to help the finished product to be superficially stable

Injection speeds: Medium to high injection speeds are more suitable for thin-walled parts or complex structures.

Standardised processing not only ensures product consistency, but also helps to reduce defect rates and improve overall production efficiency.

04 | Material PA6 B30S 000000 Datasheet

| Mechanical behavior | Condition | Standard | Value | Unit | |||

| Elongation | Yield 50mm/min | ISO 527 | 4.0/20 | % | |||

| Elongation | Break 50mm/min | ISO 527 | 20/50 | % | |||

| Flexural Strength | 2.0mm/min | ISO 178 | 110/35 | MPa | |||

| Flexural Modulus | 2.0mm/min | ISO 178 | 2900/850 | MPa | |||

| Izod Un-notch Impact | 23°C | ISO 180 | NB/NB | kJ/m² | |||

| Izod Un-notch Impact | -30°C | ISO 180 | NB/NB | kJ/m² | |||

| Izod Notch Impact | 23°C | ISO 180 | 10/30 | kJ/m² | |||

| Tensile Strength | Yield 50mm/min | ISO 527 | 80/40 | MPa | |||

| Tensile Modulus | 1.0mm/min | ISO 527 | 3200/1000 | MPa | |||

| Tensile Creep Modulus | 1hr | ISO 899 | /800 | MPa | |||

| Tensile Creep Modulus | 1000hr | ISO 899 | /600 | MPa | |||

| Charpy Un-notch Impact | 23°C | ISO 179 | NB/NB | kJ/m² | |||

| Charpy Un-notch Impact | -30°C | ISO 179 | NB/NB | kJ/m² | |||

| Charpy Notch Impact | 23°C | ISO 179 | 10/20 | kJ/m² | |||

| Charpy Notch Impact | -30°C | ISO 179 | 10/10 | kJ/m² | |||

| Thermal | Condition | Standard | Value | Unit | |||

| HDT | 0.45MPa | ISO 75 | 160 | °C | |||

| HDT | 1.8MPa | ISO 75 | 55 | °C | |||

| HDT | 8.0MPa | ISO 75 | 45 | °C | |||

| Melting Temperature | 10°C/min | ISO 11357 | 222 | °C | |||

| Vicat Softening Temperature | 50°C/hr 50N | ISO 306 | 200 | °C | |||

| Vicat Softening Temperature | 120°C/hr 50N | ISO 306 | 200 | °C | |||

| Physical property | Condition | Standard | Value | Unit | |||

| Water Absorption | 23°C | ISO 62 | 10 | % | |||

| Density | ISO 1183 | 1.14 | g/cm³ | ||||

| Electrical properties | Condition | Standard | Value | Unit | |||

| Dielectric Constant | 1MHz | IEC 60250 | 3.5/4.0 | ||||

| Dielectric Constant | 100Hz | IEC 60250 | 4.0/15 | ||||

| Volume Resistivity | IEC 60093 | 1E+15/1E+12 | Ω.cm | ||||

| Dielectric Strength | 1.0mm | IEC 60243 | 30/30 | KV/mm | |||

| Dissipation Factor | 1MHz | IEC 60250 | 0.02/0.12 | ||||

| Dissipation Factor | 100Hz | IEC 60250 | 0.017/0.2 | ||||

| Surface Resistivity | IEC 60093 | 1E14/1E13 | Ω | ||||

| Hardness | Condition | Standard | Value | Unit | |||

| Ball Indentation Hardness | ISO 2039 | 140/50 | N/mm² | ||||

| Flammability | Condition | Standard | Value | Unit | |||

| GWFI | 2.0mm | IEC 60695 | 750 | °C | |||

| Flame Rating | All Color 1.5mm | UL94 | V-2 | ||||

| Flame Rating | All Color 3.0mm | UL94 | V-2 | ||||

| Flame Rating | All Color 6.0mm | UL94 | V-2 | ||||

05 | The processor's choice

Material PA6 offers the following advantages for injection moulding plants that focus on moulding efficiency, mould protection and quick changeovers:

Glass fibre-free for less wear and tear, helping to extend the life of the moulds

Addition of release agents and lubricants improves the stability of the equipment and makes it suitable for a wide range of injection moulding machines

Ideally suited to small batch, multi-category production tasks, increasing flexibility in order intake

06 | Selecting material PA6 for eco-friendly manufacturing

With sustainable manufacturing increasingly in the global spotlight, non-reinforced material PA6 is even more recycling-friendly. PA6 B30S 000000's lack of glass fibre fillers and restrained use of heat stabilizers make it more reusable and recyclable, making it especially suitable for companies that focus on green manufacturing.

At the same time, the addition of lubricants and release agents not only optimises the moulding process, but also reduces energy consumption and mould wear, further helping companies to improve their energy efficiency and carbon management performance.

07 | Stable Supply and Service Assurance

As a professional plastic raw material trader, we have been providing LANXESS PA6 B30S 000000 virgin material PA6 pellets for a long time, and we can support the whole package shipment or according to the needs of sub-packaging. Whether you need it for new product development or high volume production, we can provide technical parameters, sample support and efficient logistics services to help you get into use quickly.

For pricing, inventory, or to obtain TDS documentation, please contact us for more information.

【Related Recommendations】

BASF PA6 B3EG6: 30% Glass Fiber Reinforced Nylon 6 for High-Flow Injection Molding Learn more>

BASF PA6 B3K: Glass-Filled Nylon for Durable Electrical Components Learn more>

Toray PA6 CM1017: Stable, Impact-Resistant Nylon 6 for Precision Parts Learn more>