PRODUCTS

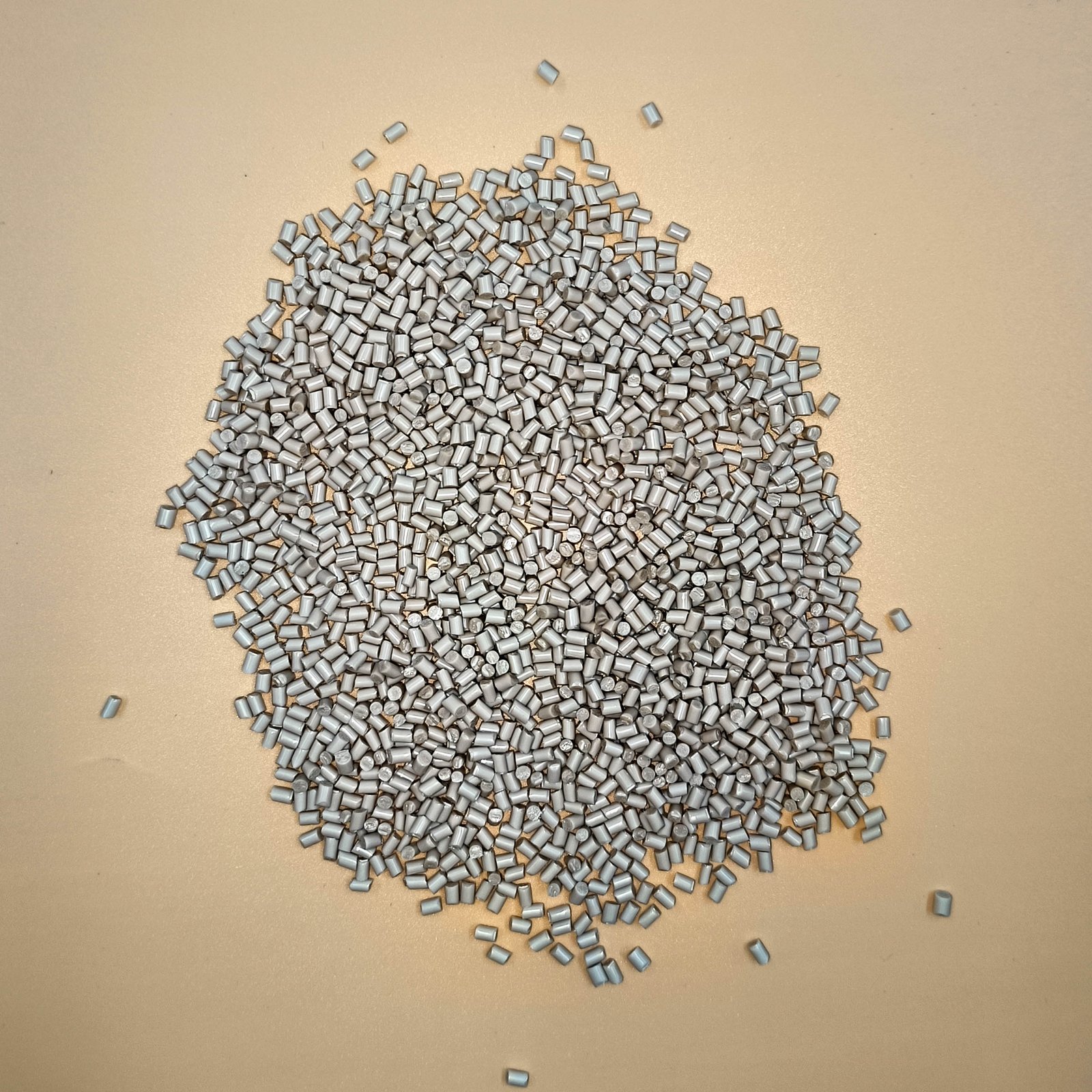

KetaSpire® KT-880 BK 95: Medical Polyether Ether Ketone PEEK

Product Struction

What is KetaSpire® KT-880

KetaSpire® KT-880 BK 95 is a member of Solvay's high-performance Polyether Ether Ketone PEEK family. While maintaining the inherent high-temperature and chemical stability of PEEK resin, this material further enhances flame retardancy, processing flow, and medical-grade biocompatibility.

Its performance covers a wide range of applications, from film and extrusion grades to medical and drinking water contact grades, providing greater design flexibility for precision components in demanding environments.

I. Key Highlights

Excellent flame retardancy: UL94 V-0 (3.0mm) is compliant, making it suitable for electrical and medical devices with stringent safety standards.

High-temperature long-term stability: RTI (Electrical/Structural) ratings are both 260°C, enabling long-term operation under high thermal and electrical stresses.

Multiple sterilization compatibility: Supports steam, autoclave, gamma irradiation, ethylene oxide, and electron beam sterilization.

Excellent dimensional stability and fatigue resistance: Ensures controlled deformation under long-term loads in medical devices and aerospace connectors. High Flow: MFR (400°C, 2.16kg) is 36 g/10min, significantly improving the efficiency of injection molding and thin-walled product processing.

II. Performance Analysis

| UL | Condition | Standard | Value | Unit | |||

| CTI | IEC 60112 | 4 | PLC | ||||

| GWFI | 0.85mm | IEC 60695-2-12 | 960 | °C | |||

| GWFI | 1.5mm | IEC 60695-2-12 | 960 | °C | |||

| GWIT | 3.0mm | IEC 60695-2-13 | 850 | °C | |||

| HAI | NC BK 0.2mm | UL 746A | 1 | PLC | |||

| HAI | NC BK 1.5mm | UL 746A | 1 | PLC | |||

| HAI | NC BK 3.0mm | UL 746A | 1 | PLC | |||

| HVTR | UL 746A | 3 | PLC | ||||

| HWI | NC BK 0.2mm | UL 746A | 3 | PLC | |||

| HWI | NC BK 1.5mm | UL 746A | 1 | PLC | |||

| HWI | NC BK 3.0mm | UL 746A | 1 | PLC | |||

| RTI | Elec NC BK 0.2mm | UL 746B | 260 | °C | |||

| RTI | Elec NC BK 0.75mm | UL 746B | 260 | °C | |||

| RTI | Imp NC BK 0.85mm | UL 746B | 180 | °C | |||

| RTI | Imp NC BK 1.5mm | UL 746B | 180 | °C | |||

| RTI | Str NC BK 1.5mm | UL 746B | 260 | °C | |||

| RTI | Str NC BK 3.0mm | UL 746B | 260 | °C | |||

| Arc Resistance | ASTM D495 | 6 | PLC | ||||

| Flame Rating | NC BK 0.2mm | UL94 | HB | ||||

| Flame Rating | NC BK 1.5mm | UL94 | HB | ||||

| Flame Rating | NC BK 3.0mm | UL94 | V-0 | ||||

| Mechanical behavior | Condition | Standard | Value | Unit | |||

| Elongation | Yield | ISO 527 | 5.0 | % | |||

| Elongation | Yield 50mm/min | ASTM D638 | 5.2 | % | |||

| Elongation | Break | ISO 527 | 10~20 | % | |||

| Elongation | Break 50mm/min | ASTM D638 | 10~20 | % | |||

| Shearing Strength | ASTM D732 | 95.1 | MPa | ||||

| Compressive Strength | ASTM D695 | 123 | MPa | ||||

| Flexural Strength | ASTM D790 | 153 | MPa | ||||

| Flexural Modulus | ISO 178 | 3900 | MPa | ||||

| Izod Un-notch Impact | ASTM D4812 | NB | |||||

| Izod Un-notch Impact | ISO 180 | NB | |||||

| Tensile Strength | 50mm/min | ASTM D638 | 100 | MPa | |||

| Tensile Strength | Yield | ISO 527 | 102 | MPa | |||

| Tensile Modulus | 1.0mm/min | ASTM D638 | 3700 | MPa | |||

| Poisson's Ratio | ASTM E132 | 0.37 | |||||

| Thermal | Condition | Standard | Value | Unit | |||

| Heat Conductivity Coefficient | ASTM E1530 | 0.25 | W/(m·K) | ||||

| Specific Heat | 50°C | ASTM C351 | 1330 | J/(kg·°C) | |||

| Specific Heat | 200°C | ASTM C351 | 1930 | J/(kg·°C) | |||

| HDT | Annealed 1.8MPa | ASTM D648 | 160 | °C | |||

| Melting Temperature | ASTM D3418 | 343 | °C | ||||

| Glass Transition Temperature | ASTM D3418 | 147 | °C | ||||

| CLE | Flow -50.0~50°C | ASTM E831 | 5E-5 | cm/cm/°C | |||

| Physical property | Condition | Standard | Value | Unit | |||

| Water Absorption | 24hr | ASTM D570 | 0.10 | % | |||

| Shrinkage | Flow | ASTM D955 | 1.4~1.6 | % | |||

| Shrinkage | xFlow | ASTM D955 | 1.5~1.7 | % | |||

| Density | ASTM D792 | 1.30 | g/cm³ | ||||

| Melt Viscosity | 400°C 1000sˉ1 | ASTM D3835 | 150 | Pa·s | |||

| Melt Index | 400°C 2.16kg | ASTM D1238 | 36 | g/10min | |||

| Electrical properties | Condition | Standard | Value | Unit | |||

| Dielectric Constant | 1KHz | ASTM D150 | 3.01 | ||||

| Volume Resistivity | ASTM D257 | 3.8E+17 | Ω.cm | ||||

| Dielectric Strength | 3.0mm | ASTM D149 | 15 | KV/mm | |||

| Dissipation Factor | 1KHz | ASTM D150 | 0.001 | ||||

| Surface Resistivity | ASTM D257 | 1.9E+17 | Ω | ||||

| Hardness | Condition | Standard | Value | Unit | |||

| Rockwell Hardness | M(Scale) | ASTM D785 | 102 | ||||

| Flammability | Condition | Standard | Value | Unit | |||

| Flame Rating | NC BK 0.2mm | UL94 | HB | ||||

| Flame Rating | NC BK 0.75mm | UL94 | HB | ||||

| Flame Rating | NC BK 3.0mm | UL94 | V-0 | ||||

Robust Mechanical Properties

Tensile strength of approximately 100 MPa and flexural strength of approximately 150 MPa, demonstrating a combination of rigidity and toughness. The material exhibits stable performance in impact and fatigue tests, making it suitable for components subjected to long-term mechanical loads.

Excellent Thermal Stability

With a high melting point of 343°C and a heat deflection temperature of approximately 160°C, it maintains structural integrity under high temperatures and repeated thermal cycling.

Excellent Electrical Insulation

Volume resistivity of approximately 3.8 × 10¹⁷ Ω·cm and dielectric strength of 15 kV/mm, it is suitable for high-voltage insulation and electronic connection systems.

Flame retardancy and strong safety

UL94 V-0 rating (3 mm), GWFI and GWIT ratings of 960°C and 850°C, respectively, demonstrate excellent flame retardancy and arc protection.

Chemical resistance and wide compatibility with sterilization

It offers stable resistance to acids, alkalis, oils, and a variety of chemical media. It is compatible with various sterilization methods, including steam, high pressure, ethylene oxide, and radiation, making it suitable for the repeated use of medical devices and industrial parts.

Iii. Process Compatibility

KetaSpire® KT-880 BK 95 has excellent processing flexibility and can be applied to various forming methods:

・Injection molding: Its melt has a relatively high fluidity (about 150 Pa·s), which can shorten the molding cycle while maintaining the precision of the product.

・Extrusion and blow molding: Suitable for the production of films, profiles and hollow products, ensuring uniform product structure.

・Thermoforming and CNC machining: It features excellent dimensional stability and can meet the secondary processing requirements of high-precision components.

In the manufacturing of medical equipment and aviation structural components, this material has good interface compatibility with metal substrates such as stainless steel and titanium alloy, supporting the integrated forming and assembly of composite parts.

Iv. Typical Application Fields

| Industry | Representative Applications | Material Advantages |

| Aerospace | Cable connectors, fuel system components | Flame retardant, lightweight, high temperature resistance |

| Medical Devices | Surgical instruments, dental components, sterilizable housings | Repeated sterilization capability, biocompatibility |

| Electrical & Electronics | Insulating brackets, sensor housings | High dielectric strength, thermal stability |

| Oil & Gas | Pump seals, valve assemblies | Chemical resistance, fatigue resistance |

| Industrial Equipment | Precision films, bearing housings | Wear resistance, low water absorption |

V. Industry Trends and Competitive Advantages

In medical and aerospace manufacturing, polyetheretherketone (PEEK) is replacing traditional metals and engineering plastics such as PPS and PEI, becoming the mainstream choice for high-end parts.

The high flowability and multi-standard certifications of KetaSpire® KT-880 BK 95 make it suitable not only for mass injection molding but also for the production of precision films and high-purity components.

It reduces molding costs without sacrificing strength, helping manufacturers achieve a balance between high performance and manufacturability.

VI. Recommended Materials Similar to KetaSpire® KT-880

| Product Model | Density | Tensile Strength | Elongation | Shrinkage | Tensile Modulus | Heat Deflection Temp. | Izod Impact (Notched) | Flexural Modulus | Izod Impact (Unnotched) | Flexural Strength | Flexural Strength |

| KT-880 BK 95 | 1.30 g/cm³ | 100 MPa | 5.00% | 1.4~1.6 % | 4000 MPa | 160 °C | 5.40 kJ/m² | 3800 MPa | — | 153 MPa | 153 MPa |

| KT-880 BK | 1.3 g/cm³ | 102 MPa | 5.20% | 1.50% | 3700 MPa | 160 °C | 53 J/m | 3800 MPa | — | 153 MPa | 153 MPa |

| KT-880 CF30 | 1.41 g/cm³ | 218 MPa | 1.70% | 0.0~0.20 % | 20900 MPa | 315 °C | 64 J/m | 17900 MPa | 640 J/m | 321 MPa | 321 MPa |

| KT-880 GF30 BG 20 | 1.53 g/cm³ | 162 MPa | 3.10% | 0.1~0.3 % | 11200 MPa | 315 °C | 7.04 kJ/m² | 10500 MPa | 86.73 kJ/m² | 260 MPa | 260 MPa |

| KT-880 FW30 | 1.45 g/cm³ | 180 MPa | 1.80% | 0.55% | 13500 MPa | — | 68 J/m | 13500 MPa | 530 J/m | 280 MPa | 280 MPa |

| KT-880 NT | 1.3 g/cm³ | 100 MPa | 5.20% | 1.40~1.60 % | 3700 MPa | 160 °C | 53 J/m | 3800 MPa | — | 153 MPa | 153 MPa |

| KT-880 GF20 | 1.46 g/cm³ | 152 MPa | 3.70% | — | 8200 MPa | — | 60 J/m | 7860 MPa | 770 J/m | 254 MPa | 254 MPa |

| KT-880 GF30 BK 95 | 1.53 g/cm³ | 162 MPa | 3.10% | 0.1~0.3 % | 11200 MPa | 315 °C | 7.04 kJ/m² | 10500 MPa | 86.73 kJ/m² | 260 MPa | 260 MPa |

| KT-880 SL30 | 1.48 g/cm³ | 162 MPa | 1.90% | 0.65~0.85 % | 14500 MPa | 293 °C | 5.83 kJ/m² | 11700 MPa | 32.1 kJ/m² | 225 MPa | 225 MPa |

| KT-880 CF40 | 1.46 g/cm³ | 258 MPa | 1.60% | — | 33000 MPa | 332 °C | 80 J/m | 30000 MPa | 750 J/m | 386 MPa | 386 MPa |

| KT-880 NL | 1.30 g/cm³ | 100 MPa | 5.20% | 1.70% | 3700 MPa | 160 °C | 53 J/m | 3800 MPa | — | 153 MPa | 153 MPa |

| KT-880 GF15 NT | 1.42 g/cm³ | 138 MPa | 5.00% | — | 6610 MPa | 278 °C | 4.79 kJ/m² | — | 67.34 kJ/m² | 231 MPa | 231 MPa |

| KT-880 CF 30 MR | 1.41 g/cm³ | 218 MPa | 1.70% | 0.10% | 20900 MPa | 315 °C | 64 J/m | 17900 MPa | 640 J/m | 321 MPa | 321 MPa |

VII. FAQ: Frequently Asked Questions Before Purchasing

Q1: What is the difference between KetaSpire® KT-880 BK 95 and standard PEEK?

A: This model is flame-retardant and medical-grade, offering enhanced sterilization compatibility and electrical safety, making it suitable for demanding industries.

Q2: Can this material be used for food contact?

A: It is certified for drinking water contact, and some batches meet food-grade requirements. We recommend verifying the compliance certificate when purchasing.

Q3: Does Juyuan offer modification solutions?

A: Juyuan can provide glass fiber reinforced, lubricated, or conductive modified versions based on customer needs to suit different operating conditions.

VIII. Juyuan - Your PEEK Supply and Technology Partner

As a supplier specializing in the international trade of plastic raw materials for 24 years, Juyuan not only provides PEEK materials from original sources but also offers modification recommendations, molding guidance, and alternative options tailored to industry needs.

Whether you're in the medical device, aviation manufacturing, or petrochemical industries, Juyuan can match you with the most suitable polyether ether ketone PEEK solution.

【Related Recommendations】

InLube™ PEEKBGHF: Lubricated PEEK Polyether Ether Ketone Learn more>

LUVOCOM® 3F PEEK CF 9676 BK: Chemical-Resistant PEEK Polymers Learn more>

Glove Materials: PVC, NBR, and TPE Cost Comparison Learn more>