PRODUCTS

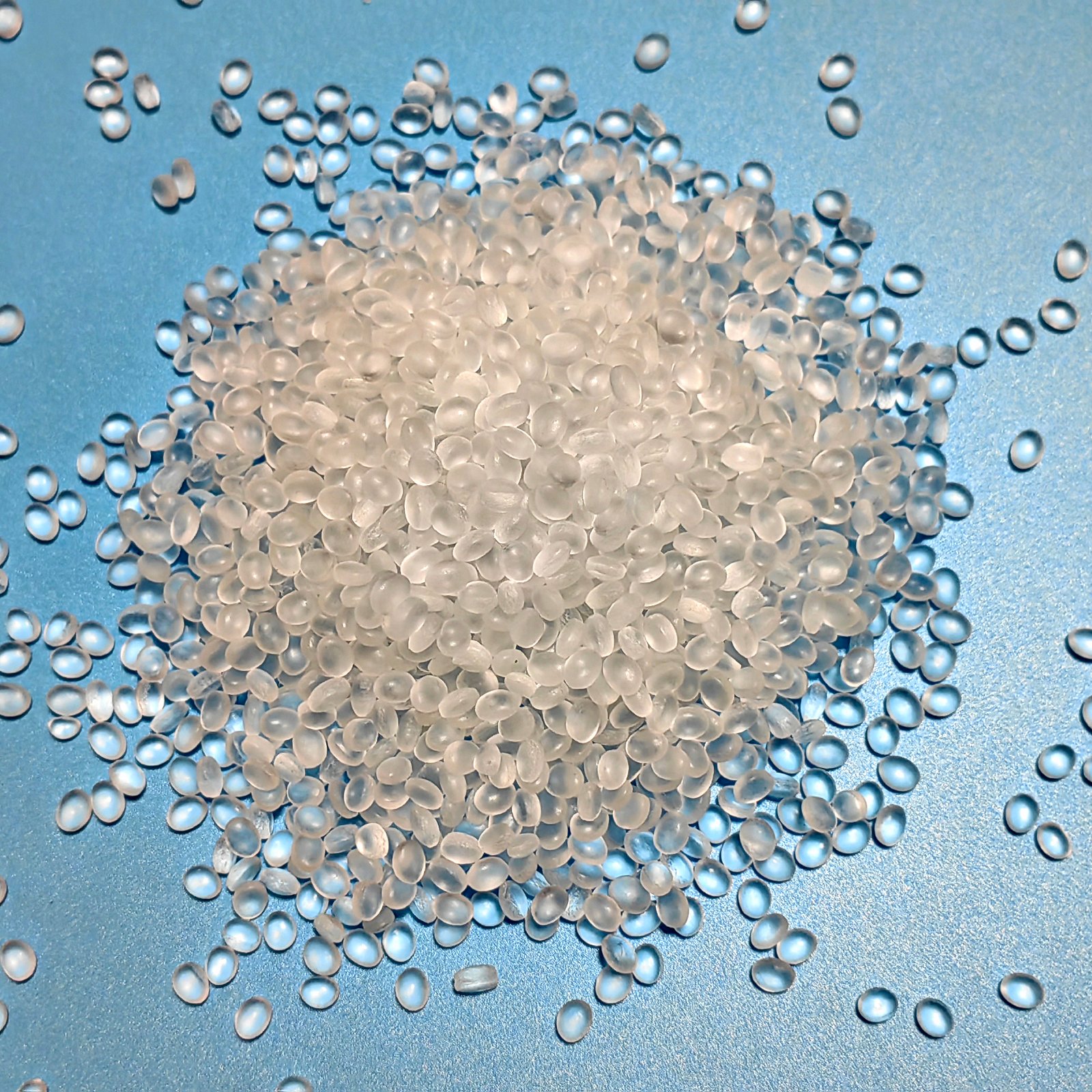

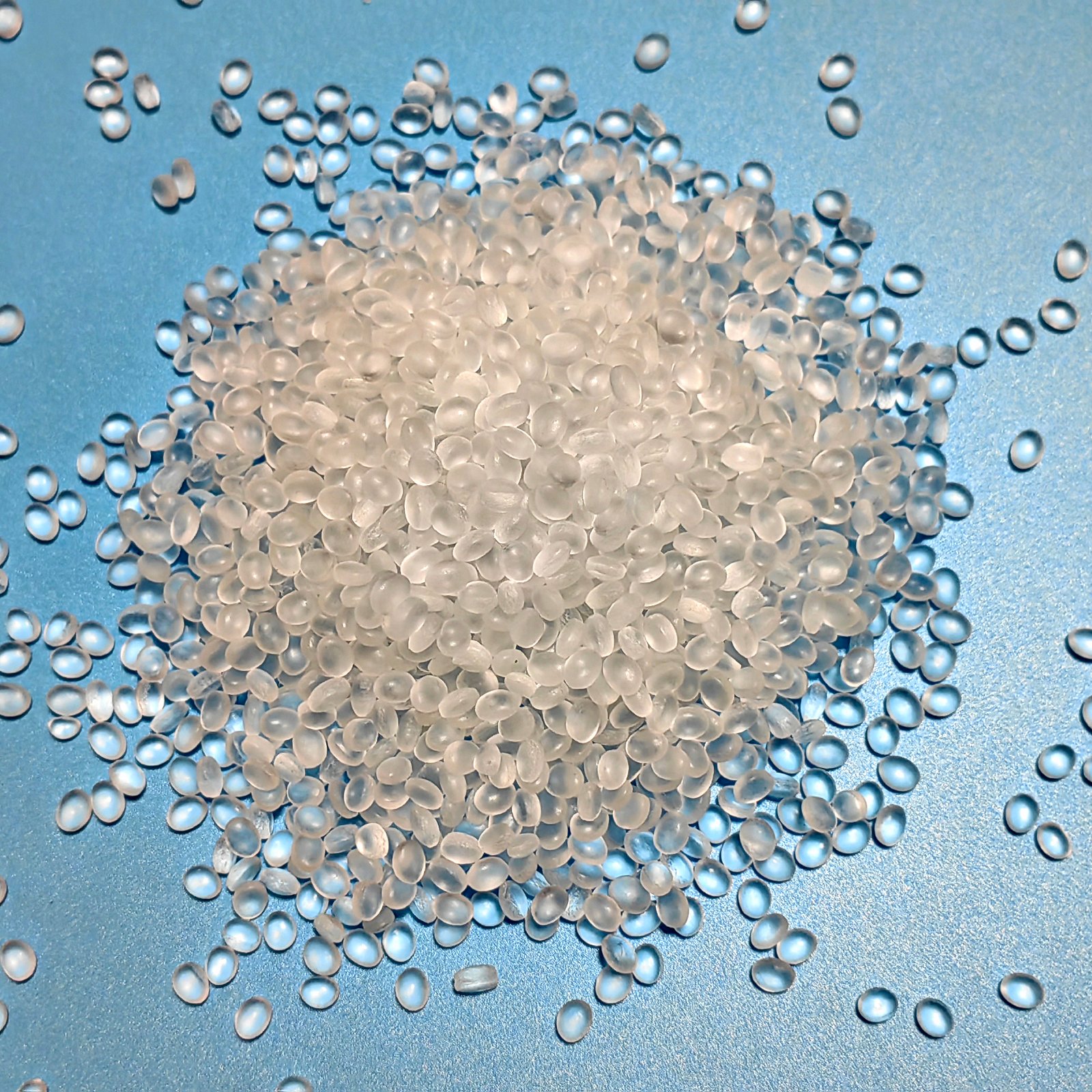

Introduction to Dow Polyolefin Elastomer POE 3401 with TDS

Product Struction

What is Polyolefin Elastomer

In the flexible packaging, film products and high-performance modification industries, how to balance softness and optical quality without sacrificing mechanical toughness has always been a difficult point in material selection. The POE 3401 Polyolefin Elastomer launched by Dow was precisely developed to address this challenge. With its excellent compatibility, resilience and flowability, it is widely used in the fields of film manufacturing and PP modification.

01 | Technical Genes:The Performance Sources of POE 3401 from the Perspective of Molecular Structure

POE 3401 adopts Dow's mature ethylene-octene copolymerization technology and combines strict control of molecular chain distribution to achieve:

✔ Medium fluidity (MFI 8 g/10min), ensuring uniform material distribution under complex structure forming processes;

✔ Uniform molecular chain structure, enhanced polymer cohesion and toughness, to avoid film breakage and fatigue in high tensile or repeated use;

✔ Excellent interfacial compatibility, so that when it is blended with PP, PE and other basic resins, the interface of material phase separation is smooth, eliminating micro-cracks and loss of performance.

The technical logic behind this is precisely the basis on which POE 3401 can gain a firm foothold in the film, flexible packaging and modification markets.

02 | Through the data, see the "hidden strength" of this material

Many enterprises' understanding of POE materials still remains at the concepts of "toughness" or "plasticizer". However, the true value of POE 3401 is far more than this:

Fatigue-resistant, soft but not soft

The elongation at break reaches 600%, and the material can maintain structural stability after multiple deformations, making it ideal for high-strength stretch films and soft covering layers.

Outstanding surface visual performance

With a gloss of 112 at 60° and a haze of only 3.2%, it far exceeds the industry's conventional level, presenting a clearer and brighter texture for the terminal products.

It is process-oriented and highly adaptable

Medium flow index (8.0g /10min), meeting the dual demands of complex structural components and high-speed production, reducing process costs and improving the yield rate.

Food contact grade certification expands the boundaries of safe application

From soft film packaging to daily-use materials, it helps enterprises lay out higher-standard consumer goods markets.

| Optical performance | Condition | Standard | Value | Unit | |||

| Gloss | 20° | ASTM D523 | 63 | ||||

| Gloss | 60° | ASTM D523 | 112 | ||||

| Haze | 2000μm Injection Molded | ASTM D1003 | 3.20 | % | |||

| Mechanical behavior | Condition | Standard | Value | Unit | |||

| Elongation | Break 50mm/min Compression Molded | ASTM D638 | 600 | % | |||

| Flexural Modulus | 1% Secabt Compression Molded | ASTM D790 | 22.7 | MPa | |||

| Tensile Strength | Break Compression Molded | ASTM D638 | 6.80 | MPa | |||

| Thermal | Condition | Standard | Value | Unit | |||

| Melting Temperature | DSC | INTERNAL METHOD | 55.0 | ℃ | |||

| Glass Transition Temperature | INTERNAL METHOD | -29.8 | ℃ | ||||

| Vicat Softening Temperature | ASTM D1525 | 20.0 | ℃ | ||||

| Physical property | Condition | Standard | Value | Unit | |||

| Density | ASTM D792 | 0.865 | g/cm³ | ||||

| Melt Index | 230℃ 2.16kg | ASTM D1238 | 8.0 | g/10min | |||

| Hardness | Condition | Standard | Value | Unit | |||

| Shore Hardness A | Compression Molded | ASTM D2240 | 72 | ||||

| Shore Hardness D | Compression Molded | ASTM D2240 | 22 | ||||

03 | Industry trend: The demand for flexible materials continues to grow, and modification innovation becomes the key

With the increasing demands for lightweight, flexibility and environmental protection in fields such as flexible packaging, medical films and functional packaging films, the market demand for polyolefin elastomers is showing a growth trend. Especially with the wide application of PP resin in the automotive, home appliance and consumer goods fields, the demand for modification of toughness and low-temperature performance is constantly increasing, which has promoted the technological innovation of POE materials.

It is precisely based on this background that POE 3401 provides a material solution that takes into account both processability and performance balance.

Typical application fields and suggestions

・Stretch film, cast film

With excellent flexibility and good transparency, it enhances the tear resistance and visual aesthetics of the film, making it suitable for packaging films and protective films.

・Soft film products

Such as soft packaging with a comfortable hand feel, medical films, and other applications that have dual demands for softness and durability.

・Modification of PP resin

It enhances the toughness, impact resistance and low-temperature performance of blended materials, and is widely used in injection molding and extrusion products, especially suitable for automobiles, home appliances and industrial products.

・Cladding molding process

With good fluidity and resilience, it helps in the manufacturing of multi-material composite structures and improves the overall performance of the products.

04 | Processing suggestions and precautions

・It is recommended for use on standard polyolefin processing equipment to adjust the melt temperature to control the thickness and appearance of the product.

・It is recommended to blend it with resins such as PP and PE. The specific proportion should be flexibly adjusted according to the modification target.

・During the processing, pay attention to the balance between the material temperature and the shear rate to avoid affecting the transparency and flexibility of the product.

05 | Why do more and more enterprises choose POE 3401?

Not only because of its performance, but also because it has solved these "pain points" in the industry:

・Does traditional PE film have a high haze and poor visual effect? POE 3401 effectively enhances transparency and glossiness;

・Are PP products prone to cracking in cold environments? Add POE 3401 to enhance toughness and impact resistance.

・Are some soft products lacking elasticity and having a hard feel during processing? The POE 3401 has excellent soft resilience and improves the terminal experience.

At the juncture where technological innovation meets market demand, choosing a suitable POE is not only an upgrade in materials but also an enhancement of an enterprise's competitiveness.

06 | Why choose us?

As a supplier with 24 years of experience in plastic trade and R&D customization, we not only provide POE 3401 raw materials, but also:

✔ We will quickly provide you with free samples for your experiments and verification.

✔ Customize modification solutions and technical support based on your specific product requirements;

✔ By leveraging abundant channel resources, ensure efficient and stable supply;

✔ Committed to innovation, we help you solve complex material challenges.

If you are interested in POE 3401 or other modification requirements, please feel free to contact us to obtain more technical information and quotation plans.

【Related Recommendations】

POE 5061: Versatile Polyolefin Elastomer for Flexible Films, Footwear and Plastic Modification Learn more>

POE 2300: Food-Grade POE Plastic Resin with High Elasticity for Toughening Applications Learn more>

Can’t Buy Labubu? Some Turned to 3D Printing—But They Missed the Most Crucial Part Learn more>