PRODUCTS

Overview of MLLDPE HP1018BM for Food Packaging

Product Struction

MLLDPE HP1018BM Introduce

mLLDPE HP1018BM is a high performance metallocene linear low density polyethylene (mLLDPE) copolymer, using a blow molding process, with excellent processing and mechanical properties. The material uses hexene copolymer and metallocene catalysis technology to improve the strength, toughness and impact resistance of the film, while having good heat sealing performance and puncture resistance, making it excellent in packaging applications.

1、The Properties of MLLDPE HP1018BM

mLLDPE HP1018BM has excellent impact resistance to falling darts and exhibits excellent durability in thin film products. The formulation contains opening agents, antioxidants, forming additives and slip enhancers, which not only improve the stability of the material, but also optimize the processing flow and surface properties, helping to increase production efficiency and improve the opening and smoothness of the film.

2、Metallocene Linear Low Density Polyethylene Applications

Metallocene LLDPE HP1018BM is widely used in industrial film, composite film, food packaging, laminated film and agricultural film and other fields, especially suitable for high strength and high toughness packaging needs. Its excellent mechanical properties and processing adaptability make it an ideal choice for packaging solutions requiring high impact resistance, high transparency and excellent heat sealing performance.

3、Metallocene LLDPE HP1018BM Parameters

| Blow Molding | Condition | Standard | Value | Unit | |||

| Blow | up Ratio | 1.5~3.0 | |||||

| Melt | Temperature | 150~180 | °C | ||||

| Mechanical behavior | Condition | Standard | Value | Unit | |||

| Elmendorf | Tear Strength Flow 25μm Film 500mm/min | ASTM D1922 | 280 | g/µm | |||

| Elmendorf | Tear Strength xFlow 25μm Film 500mm/min | ASTM D1922 | 370 | g/µm | |||

| Elongation | Flow Break 500mm/min 25μm Film | ASTM D882 | 550 | % | |||

| Elongation | xFlow Break 500mm/min 25μm Film | ASTM D882 | 640 | % | |||

| Falling | Weight Impact Strength Method A 25μm Film | ASTM D1709 | 700 | g | |||

| Secant | Modulus 1% Flow 25μm Film 500mm/min | ASTM D882 | 2800 | kg/cm² | |||

| Secant | Modulus 1% xFlow 25μm Film 500mm/min | ASTM D882 | 3100 | kg/cm² | |||

| Tensile | Strength Flow Break 500mm/min 25μm Film | ASTM D882 | 520 | kg/cm² | |||

| Tensile | Strength xFlow Break 500mm/min 25μm Film | ASTM D882 | 450 | kg/cm² | |||

| Optical performance | Condition | Standard | Value | Unit | |||

| Haze | 25μm Film | ASTM D1003 | 18 | % | |||

| Physical property | Condition | Standard | Value | Unit | |||

| Density | ASTM D1505 | 0.918 | g/cm³ | ||||

| Melt | Index 190°C 2.16kg | ASTM D1238 | 1 | g/10min | |||

| Thermal | Condition | Standard | Value | Unit | |||

| Melting | Temperature DSC | INTERNAL METHOD | 118 | °C | |||

Click here to download TDS for mLLDPE HP1018BM

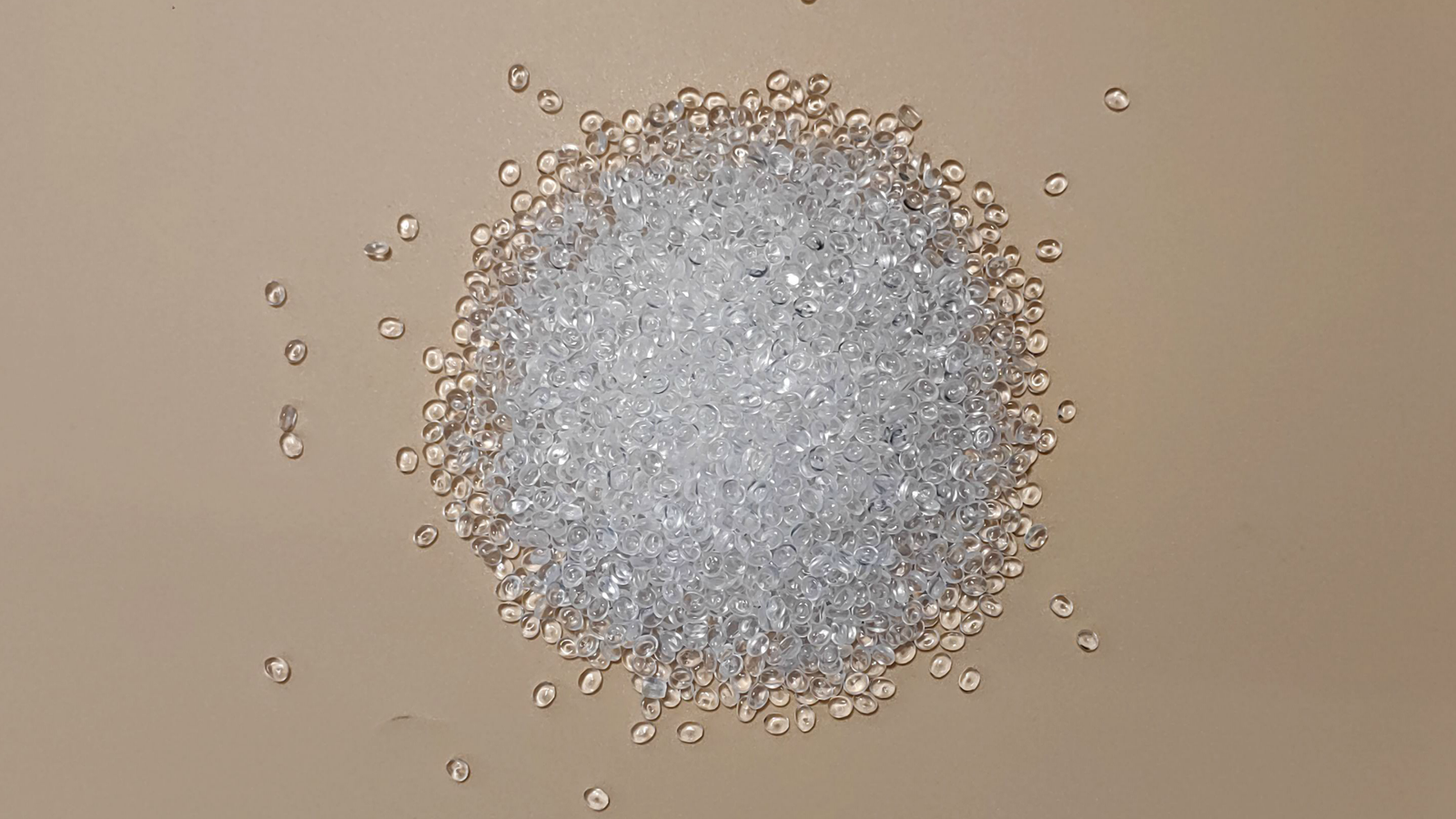

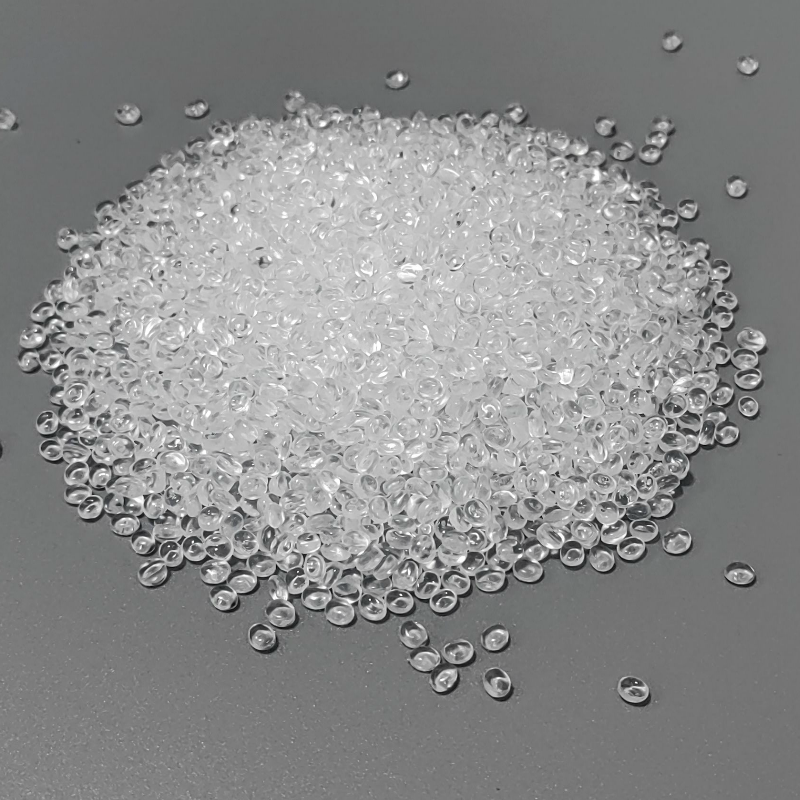

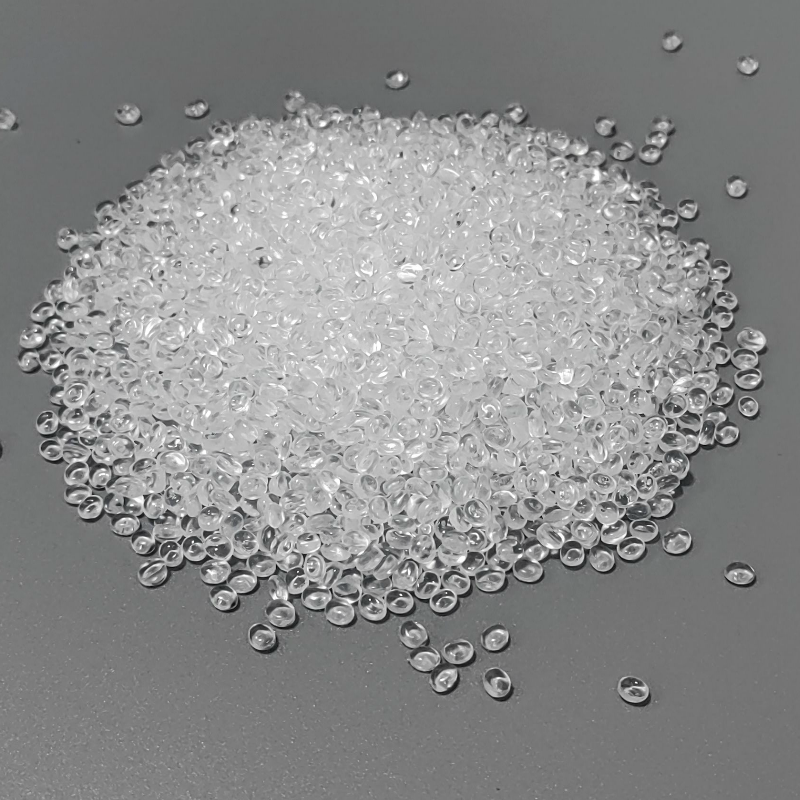

4、MLLDPE HP1018BM Granule Display

Have questions or need custom solutions? Get in touch with us for personalized advice!

【Related Recommendations】

mLLDPE D173: High-Clarity, Tough Film-Grade Mlldpe Resin for Packaging Learn more>

mLLDPE PF1315AZ: High-Performance Base Resin for Flexible Packaging & Coating Learn more>

mLLDPE D174: High-Toughness Film-Grade Copolymer for Extrusion Applications Learn more>