PRODUCTS

Overview of High Strength mLLDPE 8784MK for Blow Molding Films

Product Struction

MLLDPE 8784MK Introduction

mLLDPE 8784MK plastic pellets are a high-performance, metallocene low-density polyethylene (mLLDPE) copolymer with a natural-colored appearance, designed for the blow molding process. Its material properties include film grade and blow molding grade, and it contains an opening agent and a six-carbon copolymer, giving it excellent processing adaptability and outstanding mechanical properties.

1、MLLDPE Material Property

The material adopts ethylene -1- hexene copolymerization technology, which has high toughness, good processing stability and excellent film forming characteristics.Its low specific gravity characteristics help to reduce the amount of material used while maintaining high strength and puncture resistance.In addition, mLLDPE 8784MK provides good heat sealing performance to ensure the sealing and reliability of the package.

2、MLLDPE Pellets Use

In practical applications, the material is widely used in the production of high-quality barrier films, frozen films, laminated bags, liquid packaging and perfume bags, etc., to meet the strict requirements of food, daily chemical, medical and industrial packaging. Opening agent, heat stabilizer, forming agent and slip enhancer are added to the formula to make it have better film processing performance, improve the product's adhesion resistance, heat stability and surface smoothness, and provide an efficient and durable solution for the packaging industry.

3、MLLDPE Resin Parameters

| Mechanical behavior | Condition | Standard | Value | Unit | |||

| Elmendorf | Tear Strength Flow | ASTM D1922 | 310 | g | |||

| Elmendorf | Tear Strength xFlow | ASTM D1922 | 460 | g | |||

| Elongation | Flow Break | ASTM D882 | 330 | % | |||

| Elongation | xFlow Break | ASTM D882 | 620 | % | |||

| Falling | Weight Impact Strength | ASTM D1709 | 910 | g | |||

| Puncture | Resistance | INTERNAL METHOD | 55 | N | |||

| Puncture | Resistance | INTERNAL METHOD | 4.2 | J | |||

| Secant | Modulus 1% Flow | ASTM D882 | 170 | MPa | |||

| Secant | Modulus 1% xFlow | ASTM D882 | 210 | MPa | |||

| Tensile | Strength Flow Yield | ASTM D882 | 8.6 | MPa | |||

| Tensile | Strength xFlow Yield | ASTM D882 | 9.4 | MPa | |||

| Tensile | Strength Flow Break | ASTM D882 | 60 | MPa | |||

| Tensile | Strength xFlow Break | ASTM D882 | 50 | MPa | |||

| Optical performance | Condition | Standard | Value | Unit | |||

| Gloss | 45° | ASTM D2457 | 34 | ||||

| Haze | ASTM D1003 | 20 | % | ||||

| Physical property | Condition | Standard | Value | Unit | |||

| Density | ASTM D1505 | 0.914 | g/cm³ | ||||

| Melt | Index 190°C 2.16kg | ASTM D1238 | 0.80 | g/10min | |||

| Thermal | Condition | Standard | Value | Unit | |||

| Melting | Temperature Peak | INTERNAL METHOD | 121 | °C | |||

Click here to download TDS for mLLDPE 8784MK

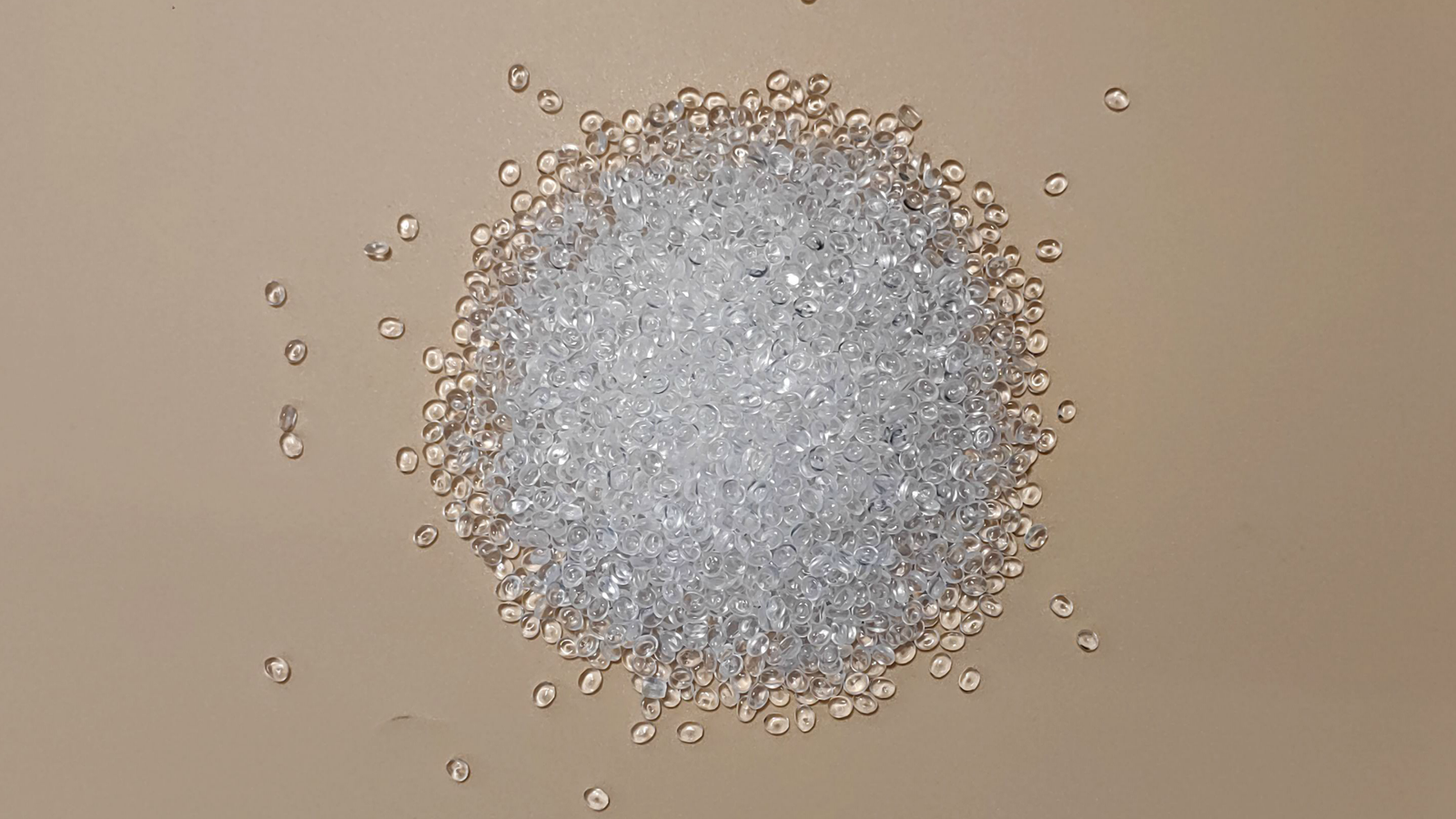

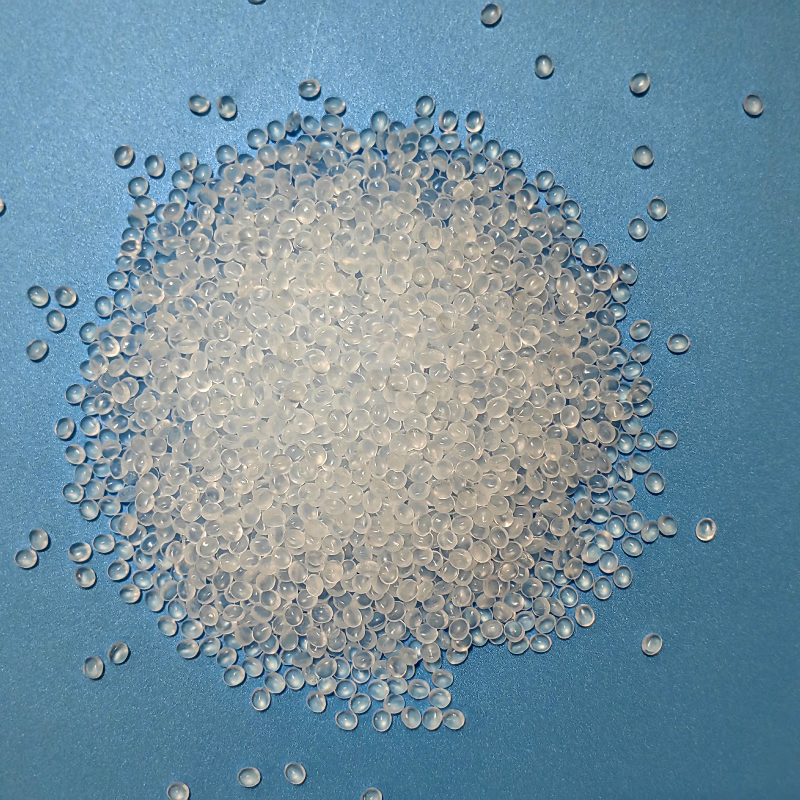

4、Metallocene LLDPE Granule Display

Get started with a free consultation—contact us to find out how we can help you!

【Related Recommendations】

mLLDPE HP1018BM: High-Impact Resistant mLLDPE for Durable Packaging & Film Applications Learn more>

MLLDPE 3518CB: High-Performance mLLDPE for Extrusion & Blow Molding Learn more>

mLLDPE 1327MD: High-Performance Film-Grade mLLDPE for Food Packaging Learn more>