PRODUCTS

ABS Material Overview | High-Flow ABS PA-737 for Automotive

Product Struction

What is ABS Material?

ABS PA-737 is a high-quality ABS material developed specifically for injection molding and performs well in a variety of industrial scenarios.

1、ABS Material Properties

Appearance: ABS PA-737 material has smooth surface and beautiful appearance, which meets the appearance requirements of high-end products.

Fluidity: Good fluidity, can be quickly and evenly filled in complex molds, improve molding efficiency and accuracy.

Processing performance: high processing stability, good thermal stability, easy to achieve high precision molding.

Processing speed: With fast processing characteristics, suitable melt viscosity and crystallization characteristics, can shorten the production cycle.

Flame retardant: up to HB flame retardant standard, under specific test conditions, the burning speed can be controlled, and the fire source will self-extinguish after withdrawal to ensure safety.

2、ABS Material Application

Automotive industry: ABS material Used for automotive interior and exterior decoration and some functional parts, taking into account beauty, durability and safety.

Office equipment manufacturing: Suitable for office equipment shell, improve appearance and reliability.

Home appliance industry: Manufacture home appliance housings to enhance aesthetics, safety and service life.

Thin-walled products production: Due to good fluidity and fast processing characteristics, to meet the packaging, electronics and other industries of thin-walled products demand.

3、The effect of additives

Add lubricant and release agent to enhance processing performance. Lubricants reduce friction between molecular chains, improving fluidity and minimizing equipment wear. Meanwhile, the release agent forms an isolation film between the product and the mold, facilitating smooth release, increasing production efficiency, and ensuring better product quality.

4、ABS Material Datasheet

| Flammability | Condition | Standard | Value | Unit | |||

| Flame | Rating All Color 1.5mm | UL94 | HB | ||||

| Flame | Rating All Color 3.0mm | UL94 | HB | ||||

| Hardness | Condition | Standard | Value | Unit | |||

| Rockwell | Hardness R(Scale) | ASTM D785 | 103 | ||||

| Mechanical behavior | Condition | Standard | Value | Unit | |||

| Charpy | Notch Impact 23°C | ISO 179 | 25 | kJ/m² | |||

| Charpy | Notch Impact -30°C | ISO 179 | 11 | kJ/m² | |||

| Elongation | 6mm/min | ASTM D638 | 22 | % | |||

| Elongation | 50mm/min | ISO 527 | 20 | % | |||

| Flexural | Strength 2.8mm/min | ASTM D790 | 590 | kg/cm² | |||

| Flexural | Strength 2.0mm/min | ISO 178 | 60 | MPa | |||

| Flexural | Modulus 2.8mm/min | ASTM D790 | 20000 | kg/cm² | |||

| Flexural | Modulus 2.0mm/min | ISO 178 | 1.9 | GPa | |||

| Izod | Notch Impact 23°C 6.4mm | ASTM D256 | 18 | kg-cm/cm | |||

| Izod | Notch Impact 23°C 3.2mm | ASTM D256 | 25 | kg-cm/cm | |||

| Izod | Notch Impact 23°C | ISO 180 | 24 | kJ/m² | |||

| Izod | Notch Impact -30°C | ISO 180 | 10 | kJ/m² | |||

| Tensile | Strength Yield 6mm/min | ASTM D638 | 360 | kg/cm² | |||

| Tensile | Strength Yield 50mm/min | ISO 527 | 38 | MPa | |||

| Tensile | Strength Break 50mm/min | ISO 527 | 32 | MPa | |||

| Physical property | Condition | Standard | Value | Unit | |||

| Density | 23°C | ASTM D792 | 1.04 | g/cm³ | |||

| Density | 23°C | ISO 1183 | 1.04 | g/cm³ | |||

| Melt | Index 200°C 5kg | ASTM D1238 | 2.6 | g/10min | |||

| Melt | Index 220°C 10kg | ISO 1133 | 31 | cm³/10min | |||

| Shrinkage | ISO 294 | 0.4~0.7 | % | ||||

| Thermal | Condition | Standard | Value | Unit | |||

| CLE | ISO 11359 | 9E-5 | cm/cm/°C | ||||

| HDT | Annealed 1.8MPa | ASTM D648 | 93 | °C | |||

| HDT | Unannealed 1.8MPa | ASTM D648 | 83 | °C | |||

| HDT | Unannealed 1.8MPa | ISO 75 | 81 | °C | |||

| HDT | Annealed 1.8MPa | ISO 75 | 96 | °C | |||

| Vicat | Softening Temperature 50°C/hr 10N | ASTM D1525 | 101 | °C | |||

| Vicat | Softening Temperature 50°C/hr 10N | ISO 306 | 103 | °C | |||

| Vicat | Softening Temperature 50°C/hr 50N | ISO 306 | 96 | °C | |||

| UL | Condition | Standard | Value | Unit | |||

| Arc | Resistance | ASTM D495 | 7 | PLC | |||

| Comparative | Tracking Index | IEC 60112 | 1 | PLC | |||

| HAI | ALL 1.5mm | UL 746A | 0 | PLC | |||

| HAI | ALL 3.0mm | UL 746A | 0 | PLC | |||

| HVTR | UL 746A | 0 | PLC | ||||

| HWI | ALL 1.5mm | UL 746A | 4 | PLC | |||

| HWI | ALL 3.0mm | UL 746A | 4 | PLC | |||

| RTI | Elec ALL 1.5mm | UL 746B | 60 | °C | |||

| RTI | Elec ALL 3.0mm | UL 746B | 60 | °C | |||

| RTI | Imp ALL 1.5mm | UL 746B | 60 | °C | |||

| RTI | Imp ALL 3.0mm | UL 746B | 60 | °C | |||

| RTI | Str ALL 1.5mm | UL 746B | 60 | °C | |||

| RTI | Str ALL 3.0mm | UL 746B | 60 | °C | |||

| UL | FlameRating ALL 1.5mm | UL94 | HB | ||||

| UL | FlameRating ALL 3.0mm | UL94 | HB | ||||

Click here to download TDS for ABS PA-737

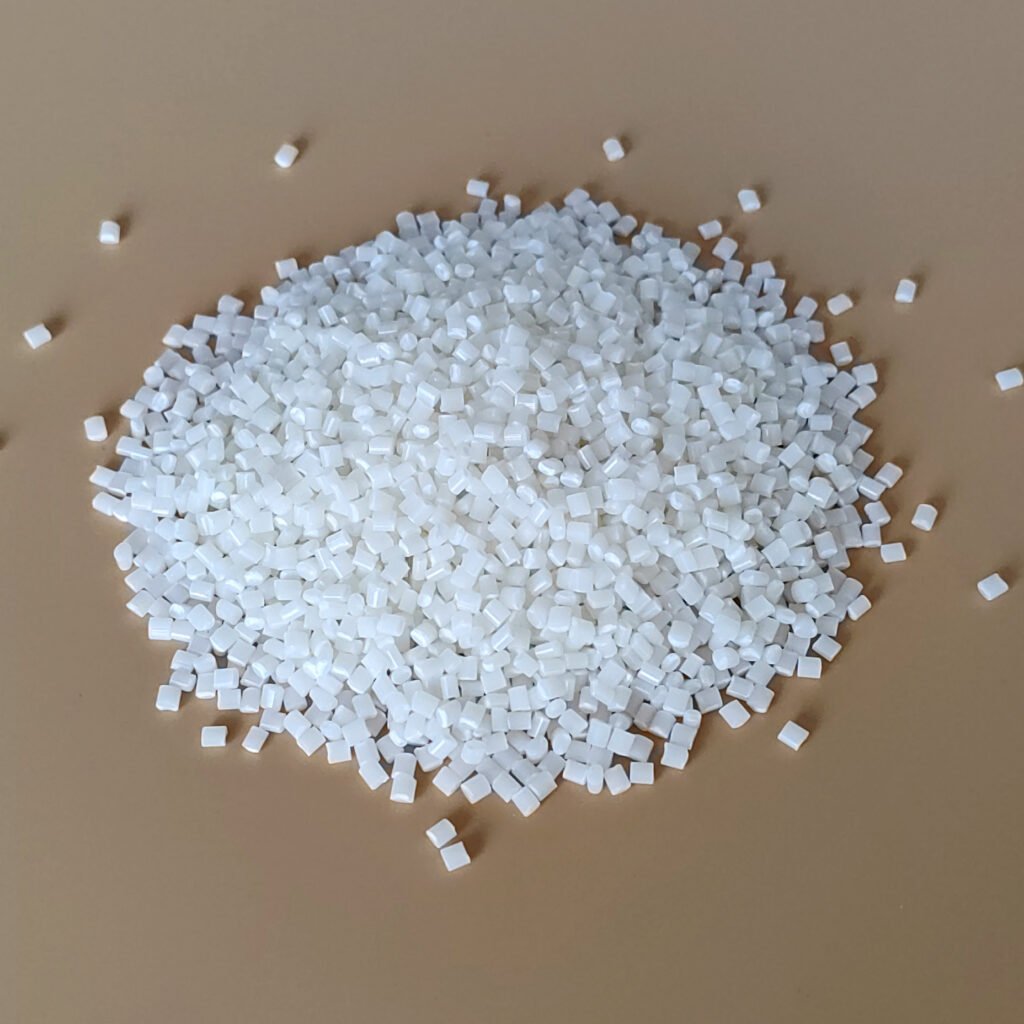

5、ABS Material Display

6、Conclusion

ABS PA-737 material has excellent performance and is widely used in automotive, office equipment, home appliances and other fields, making it an ideal material for injection molding. With the development of technology, it is expected to expand more application scenarios.

【Related Recommendations】

What material is ABS? Learn more>

ABS D-90 Pellets:High Gloss, Rigid Injection Molding ABS for Electronics Learn more>

ABS PA-747H:Durable, Chemically Resistant ABS Plastic for Home Appliances Learn more>