PRODUCTS

High-Clarity mLLDPE XP9100 Properties Uses and Technical Data

Product Struction

What is MLLDPE XP9100?

MLLDPE XP9100 plastic pellets are a metallocene linear low density polyethylene (mLLDPE) copolymer that is ideal for blow molding processes. The mlldpe plastic granules meets food contact grade standards to ensure safe and hygienic packaging. The material contains an opening agent that can effectively improve the processability of the film to meet the needs of different packaging applications. The high clarity and gloss of the material give it a good appearance in the packaging.

1、The Properties of MLLDPE XP9100

High shrinkage ensures a tight fit of packaging in shrink film applications, while high toughness and stiffness provide excellent mechanical properties. Low temperature heat sealing performance reduces sealing energy consumption, and low extractability improves the food safety of the material. The use of metallocene catalytic systems provides more stable processability and uniform molecular structure.

2、Metallocene Linear Low Density Polyethylene Applications

The mLLDPE XP9100 is mainly used for heavy duty bags and shrink film to provide effective protection during transportation and storage. Heavy-duty bags are used for high-volume packaging of food and industrial products, while shrink films are widely used for packaging of electronics and consumer goods. Its excellent physical properties and food safety make it an ideal choice for high-performance packaging materials.

3、Product Parameters

| Mechanical behavior | Condition | Standard | Value | Unit | |||

| Elongation | Flow Break | ASTM D882 | 630 | % | |||

| Elongation | xFlow Break | ASTM D882 | 650 | % | |||

| Falling | Weight Impact Strength Method A | ASTM D1709 | 300 | g | |||

| Tearing | Strength Flow | ASTM D1004 | 140 | kg/cm | |||

| Tearing | Strength xFlow | ASTM D1004 | 145 | kg/cm | |||

| Tensile | Strength Flow Break | ASTM D882 | 580 | kg/cm² | |||

| Tensile | Strength xFlow Break | ASTM D882 | 530 | kg/cm² | |||

| Optical performance | Condition | Standard | Value | Unit | |||

| Gloss | 45° | ASTM D2457 | 85 | ||||

| Haze | ASTM D1003 | 10 | % | ||||

| Physical property | Condition | Standard | Value | Unit | |||

| Density | ASTM D1505 | 0.925 | g/cm³ | ||||

| Melt | Index 190°C 2.16kg | ASTM D1238 | 0.8 | g/10min | |||

| Thermal | Condition | Standard | Value | Unit | |||

| Heat | Seal Temperature 2.8kg 0.5s | INTERNAL METHOD | 118 | °C | |||

| Melting | Temperature | ASTM D3418 | 119 | °C | |||

| Vicat | Softening Temperature | ASTM D1525 | 117 | °C | |||

Click here to download TDS for mLLDPE XP9100

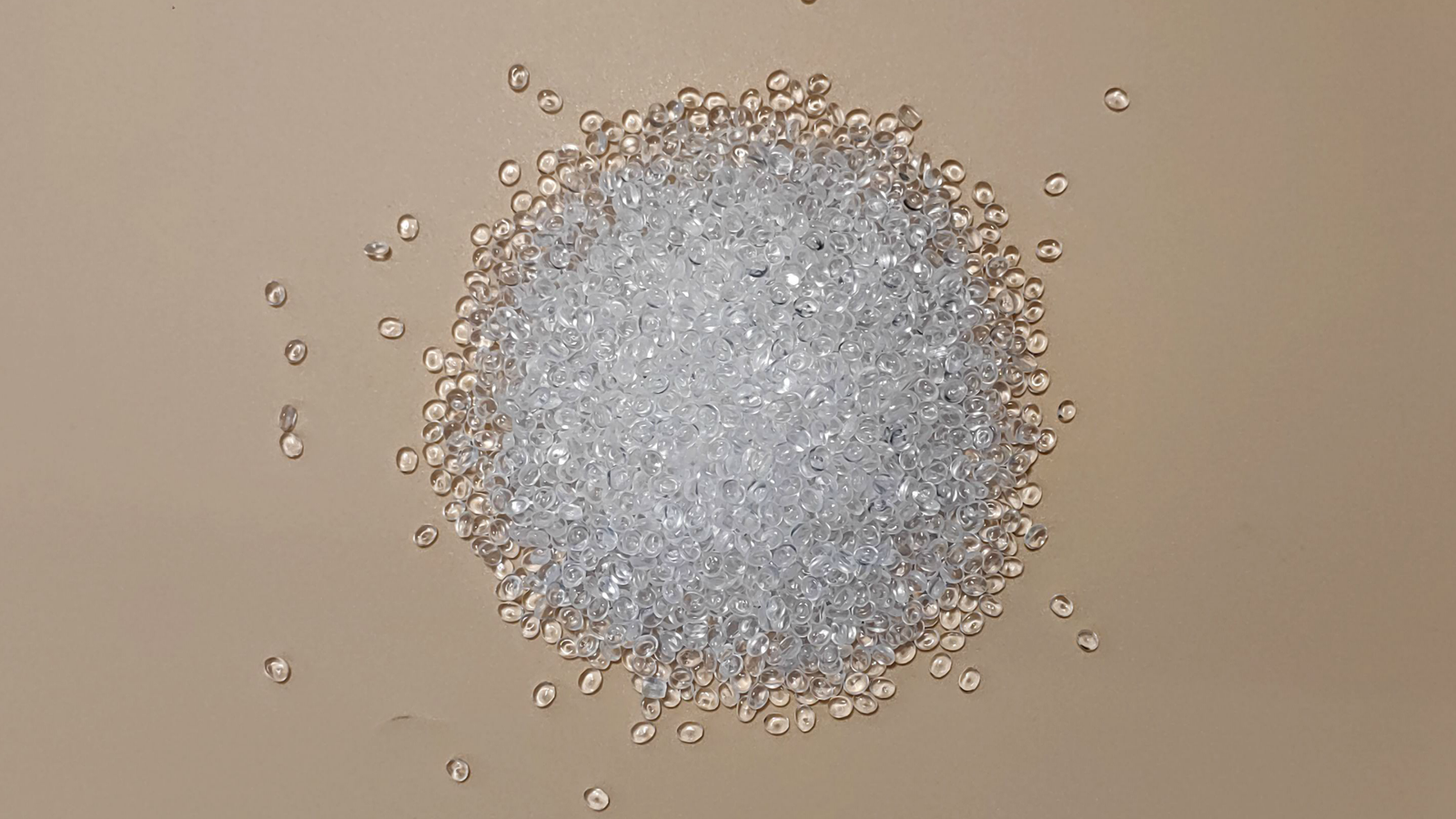

4、Prouduct Display

For more details on material and how it can benefit your business, reach out to us!

【Related Recommendations】

mLLDPE 1018MF: High-Performance mlldpe Resin for Agricultural Packaging Learn more>

mLLDPE SP0540: High-Performance metallocene LLDPE for Film Extrusion Learn more>

mLLDPE SP1520: High-Performance mlldpe granule for Agricultural Films Learn more>