PRODUCTS

ExxonMobil POE Polymers 8203 Properties Uses and TDS

Product Struction

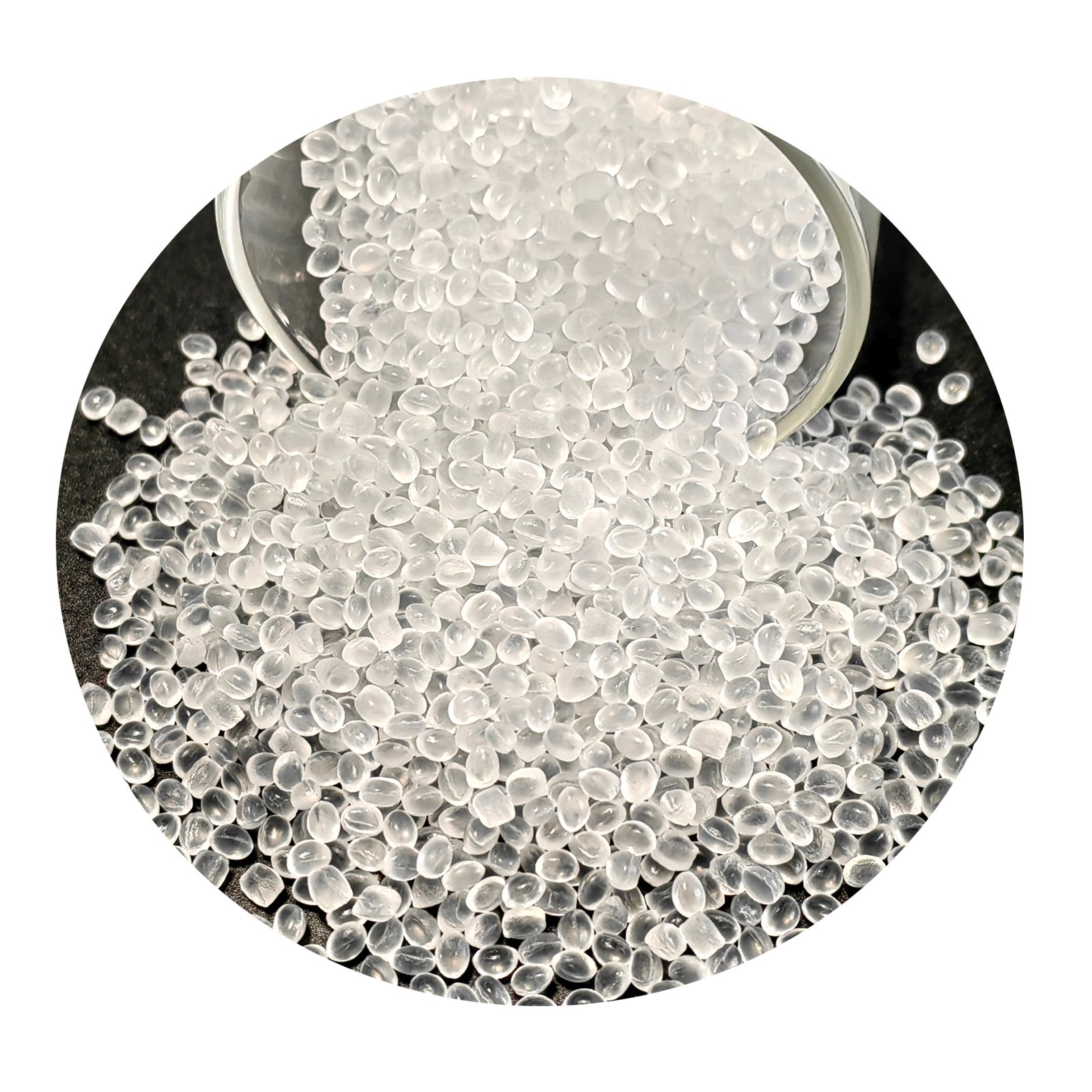

POE Polymers Overview - ExxonMobil POE 8203

Today, with the rapid development of polyolefin elastomers (POE polymers), ExxonMobil POE 8203, as an eight-carbon POE material with multiple performance advantages, has demonstrated extremely strong adaptability in multiple industries with its flexibility, transparency and low-temperature toughness. From high-strength flexible films to cable insulation, from automotive interiors to functional foam materials, POE 8203 is no longer a "traditional modified additive", but one of the core materials driving innovation.

01 | POE polymers properties: The "Way of balance" where softness and toughness coexist

POE 8203 is an octa-carbon olefin copolymer produced by solution polymerization technology. It has a uniform structure and orderly arrangement of molecular chains, which makes it show significant advantages in the following aspects:

・Extremely high elongation (2000%) : It demonstrates super strong ductility, especially suitable for sealing films and elastic layers that require high deformation.

・Outstanding softness: With A Shore A hardness of 85, it has a rubber-like feel but also possesses excellent tensile strength (22 MPa).

・Excellent low-temperature performance: Even at -40°C, the notched impact test shows no cracking (NB), and the embrittlement temperature is as low as -75°C, making it suitable for applications in extremely cold environments.

・Mild thermal performance: With a melting point of 72°C, it is suitable for medium and low-temperature processing systems, and the average melting heat reaches 100 J/g, providing better energy consumption control.

・Stable dielectric properties: The extremely low dielectric constant and loss factor make it an ideal low-voltage insulating material.

02 | Key advantage: Evolution from "modifiers" to "functional materials"

POE 8203 is not merely a formula ingredient used to "enhance flexibility". It has been regarded by an increasing number of enterprises as part of the functional structure:

・High transparency and low haze (2.4%) make it suitable for film packaging with high visual aesthetics requirements.

・High processing adaptability: Whether it is extrusion, blow molding or extrusion coating, a uniform surface and ideal thickness control can be achieved.

・Strong puncture resistance: Especially suitable for applications such as stretch films and transport protective films that have high tolerance requirements for mechanical damage.

・Good thermal stability and environmental stress cracking life (1000 hours) : Suitable for long-term outdoor usage scenarios, such as roof waterproof membranes, tunnel linings, etc.

03 | Innovative application scenarios: The diversified future of POE 8203

Thanks to its balanced mechanical properties and excellent low-temperature elasticity, POE polymers 8203 is being widely applied in the following innovative scenarios:

・PP modification and toughening: Endows rigid materials with flexible buffering performance and is an ideal flexibility regulator for halogen-free flame retardant systems.

・Eco-friendly foam and cork stopper alternative materials: Sustainable foam solutions for replacing PVC or TPR.

・Extruded coating materials: Provide a soft yet tear-resistant protective layer on textile film layers and construction fabrics.

・Synthetic cork stoppers and functional insole materials: Combining excellent resilience and processing molding properties, expanding the boundaries of consumer products.

04 | Key Performance Data of POE 8203

| Optical performance | Condition | Standard | Value | Unit | |||

| Gloss | ASTM D2457 | 83 | |||||

| Haze | ASTM D1003 | 2.4 | % | ||||

| Mechanical behavior | Condition | Standard | Value | Unit | |||

| Elongation | 23°C | ISO 527 | 2000 | % | |||

| Flexural Modulus | 23°C | ISO 178 | 28 | MPa | |||

| Izod Notch Impact | 23°C | ASTM D256 | NB | kJ/m² | |||

| Izod Notch Impact | -40°C | ASTM D256 | NB | kJ/m² | |||

| Tensile Strength | 23°C | ISO 527 | 22 | MPa | |||

| Tensile Modulus | Flow 23°C 1% Secant | ASTM D882 | 24 | MPa | |||

| Tensile Modulus | xFlow 23°C 1% Secant | ASTM D882 | 24 | MPa | |||

| Falling Weight Impact Strength | 16 | ||||||

| Thermal | Condition | Standard | Value | Unit | |||

| Average Heat of Fusion | ASTM D3418 | 100 | J/g | ||||

| Melting Temperature | ASTM D3418 | 72 | °C | ||||

| Vicat Softening Temperature | 50°C/hr 10N | ISO 306 | 51 | °C | |||

| Low temperature Brittleness | ASTM D746 | -75.0 | °C | ||||

| Physical property | Condition | Standard | Value | Unit | |||

| Density | ISO 1183 | 0.882 | g/cm³ | ||||

| Melt Index | 190°C 2.16kg | ISO 1133 | 3 | g/10min | |||

| Environmental Stress Crack Resistance | ASTM D1693 | 1000 | hr | ||||

| Hardness | Condition | Standard | Value | Unit | |||

| Shore Hardness A | 15s | ISO 868 | 85 | ||||

| Shore Hardness D | 15s | ISO 868 | 28 | ||||

05 | Application suggestions and processing key points

・Suggested processing temperature: It is recommended that the melting temperature be controlled within the range of 150 to 180°C to ensure that the flexible structure is not damaged.

・The recommended addition amount when blending with PP or EVA: According to the target flexibility and impact requirements, it can be controlled between 15% and 40%.

・Molding precautions: It is recommended to use processing stabilizers and antioxidants in combination to extend the processing window and avoid yellowing.

06 | Why choose POE 8203?

・Want to enhance flexibility without sacrificing transparency and appearance?

・Hope the product won't crack at extremely low temperatures?

・Is it necessary for the material to have good dielectric properties and tear resistance?

・Looking for a modified material with strong processability and easy compatibility with multiple polymer systems?

POE 8203 is the answer.

Obtain samples and technical information immediately

We provide technical Data Sheets (TDS), typical processing guidelines and application cases. Welcome to contact us for free samples and customized modification suggestions. Let's work together to create more flexible and competitive solutions.

【Related Recommendations】

POE 8003: Crosslinkable Polyolefin Elastomer for Lightweight Design Learn more>

POE 8150: Functional Polyolefin Elastomer for Structural Toughening Learn more>

POE 8100: Crosslinkable Polyolefin Elastomer for High-Fill and Flexible Cable Applications Learn more>