PRODUCTS

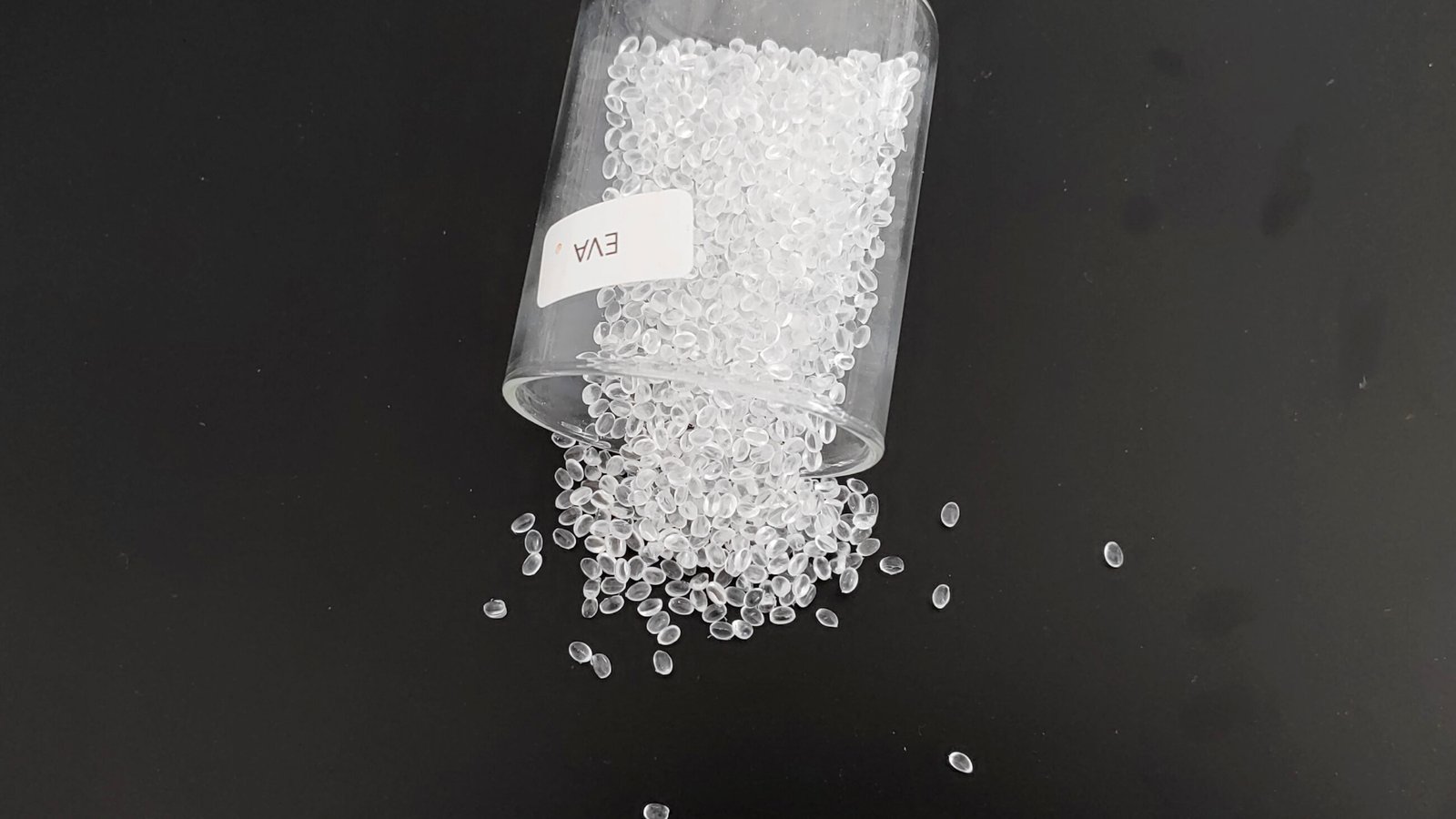

EVA Plastic Introduce | Low-Melt EVA 2518 CO for Foam Shoes

Product Struction

What is EVA Plastic?

EVA 2518 CO is a high-performance EVA plastic containing 18% ethylene vinyl acetate (VA) designed for foam moulding and a variety of processing applications. The material is produced by IPC, a division of Sipchem, Saudi Arabia, using ExxonMobil's high-pressure tubular process to ensure superior product quality and consistency.

What are the Properties of EVA 2518 CO?

Excellent mechanical properties for injection, extrusion and composite moulding, providing good toughness and elasticity.

Low melting point, easy to process, can meet the foam moulding, profile manufacturing and other process needs.

Outstanding fluidity to ensure stable flow during processing and improve the quality of finished products.

What are EVA Plastic used for?

EVA 2518 CO is suitable for a wide range of industrial and consumer applications, especially in foam moulding:

Foam footwear & shoe soles:

suitable for sports shoes, slippers, sandals, etc. It combines the advantages of extrusion and injection moulding to provide lightweight and comfort.

Composite Materials & Composite forming:

EVA plastic performs well in composite molding, significantly improving material adhesion and enhancing the overall performance of the product, while perfectly adapting the composite molding process to ensure efficient production.

Profiles Industrial Applications:

This material is widely used in pipes, seals and other industrial fields, relying on extrusion technology to give products high strength and durability to meet the demanding industrial needs.

Foaming material:

EVA 2518 CO plastic is ideal for the manufacture of cushioning materials, packaging and household items, and supports the foam forming process to easily achieve lightweight, soft and durable foam products.

EVA Plastic Product Parameters

| Hardness | Condition | Standard | Value | Unit | |||

| Shore | Hardness A | ASTM D2240 | 76 | ||||

| Shore | Hardness D | ASTM D2240 | 36 | ||||

| Mechanical behavior | Condition | Standard | Value | Unit | |||

| Elongation | Yield | ASTM D638 | 260 | % | |||

| Elongation | Break | ASTM D638 | 800 | % | |||

| Flexural | Modulus | ASTM D790 | 60 | MPa | |||

| Tensile | Strength Yield | ASTM D638 | 5.2 | MPa | |||

| Tensile | Strength Break | ASTM D638 | 11 | MPa | |||

| Physical property | Condition | Standard | Value | Unit | |||

| Density | ASTM D1505 | 0.935 | g/cm³ | ||||

| Melt | Index 190°C 2.16kg | ASTM D1238 | 2.5 | g/10min | |||

| Vinyl | Acetate Content | 18 | wt% | ||||

| Thermal | Condition | Standard | Value | Unit | |||

| Melting | Temperature | ASTM D3418 | 87 | °C | |||

| Vicat | Softening Temperature | ASTM D1525 | 64 | °C | |||

Click here to download TDS for EVA 2518 CO

Contact Us for EVA Plastic Details!

As a high-performance EVA plastic, EVA 2518 CO has excellent mechanical properties, low melting point and excellent processing adaptability, which is the ideal choice for foam footwear, composite materials, profiles and other fields. If you need EVA 2518 CO plastic for foam forming, please contact us for more technical support and cooperation solutions!

【Related Recommendations】

EVA VS430 Resin: High-Performance EVA copolymer for Foaming Learn more>

EVA EA28400: High-Performance EVA resin for Hot Melt Adhesives Learn more>

Food-Grade EVA 260 Granules: Reliable Performance for Various Processing Needs Learn more>