PRODUCTS

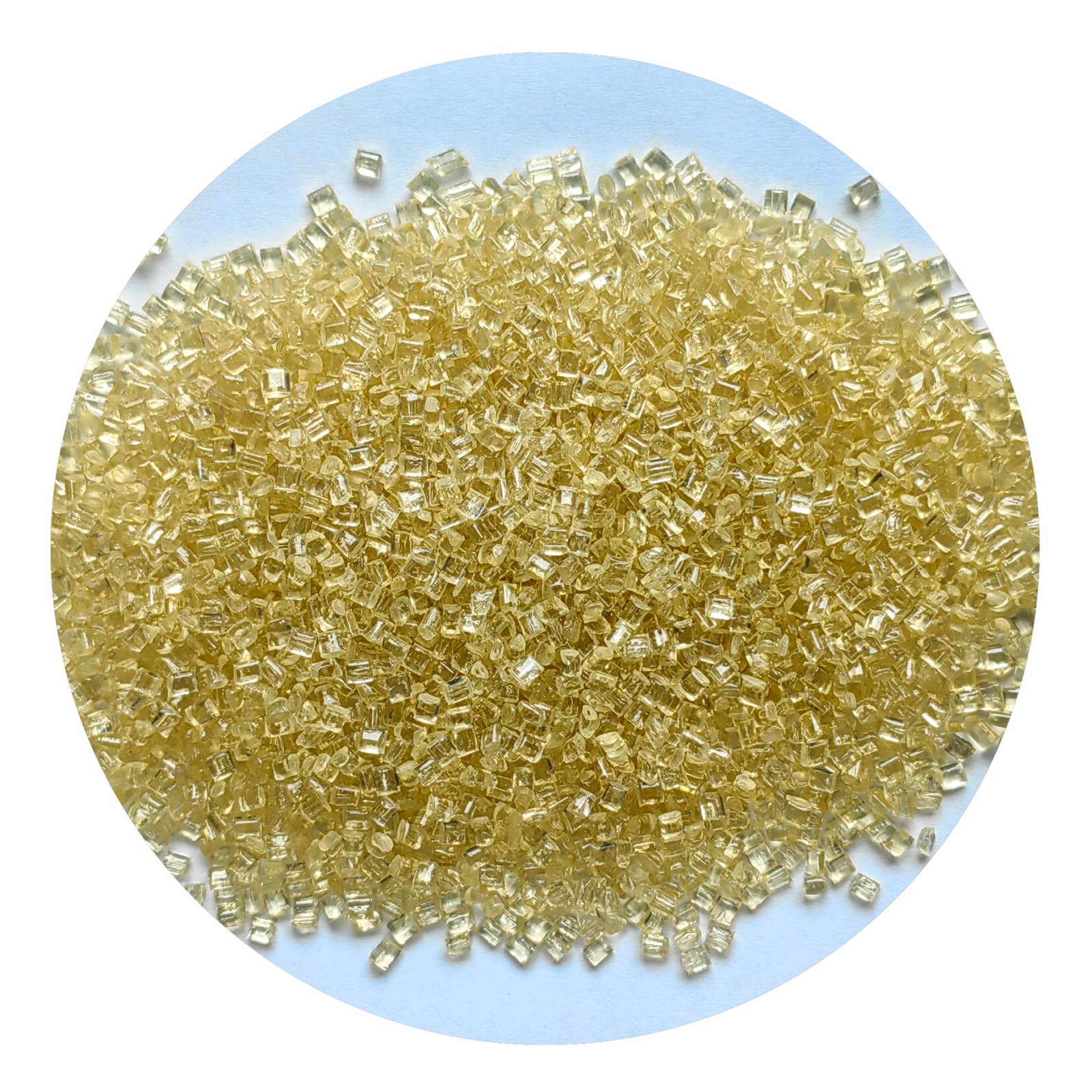

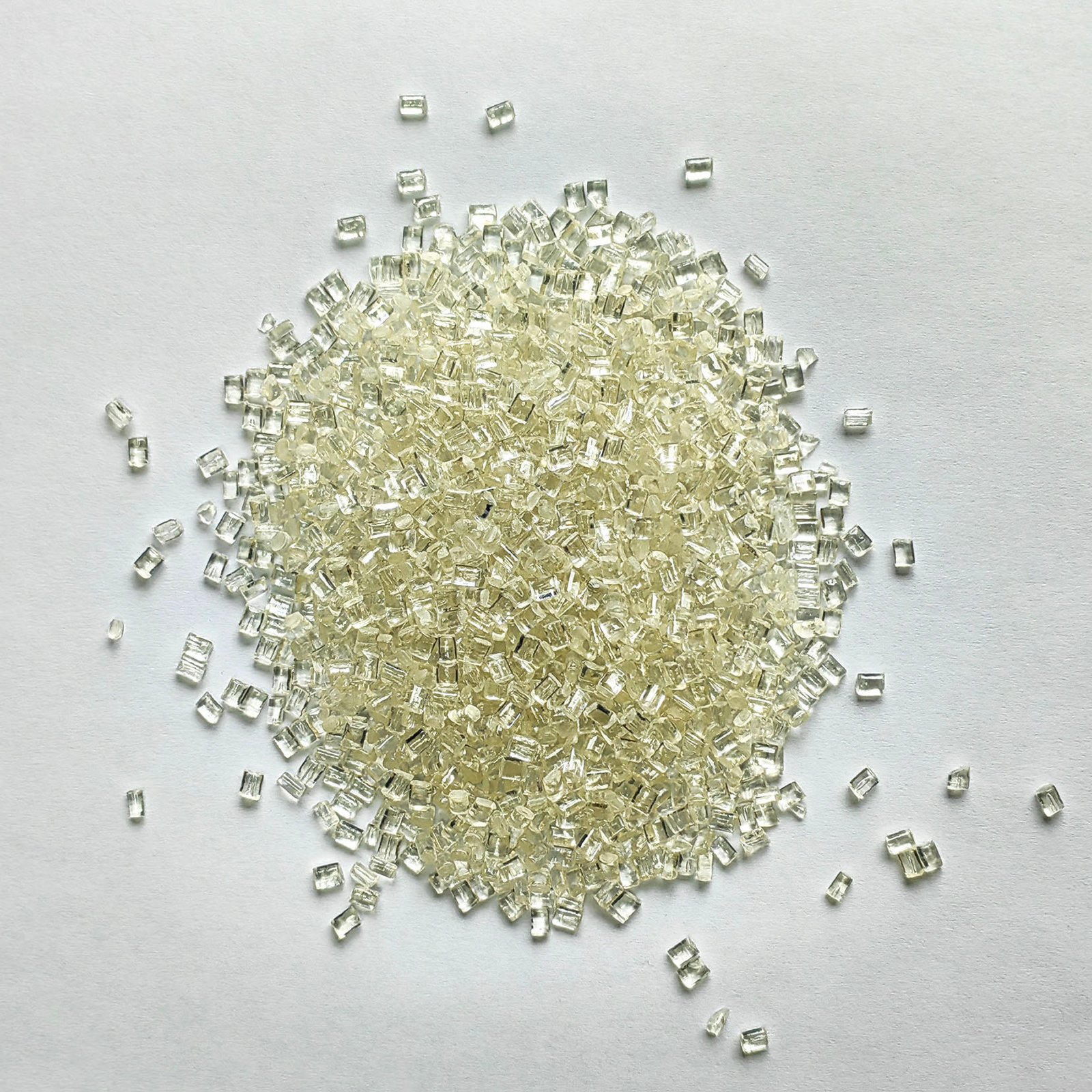

Enviroplas ENV48-NC570 | Oil Resistance PSU Plastic for Medical

Product Struction

What is PSU Plastic

In the global application of engineering plastics, PSU plastic has gradually expanded from the traditional fields of electronics and medical care to household appliances, automobiles, energy and drinking water systems. Its unique advantage lies in the fact that it can withstand high temperatures while maintaining long-term stable physical properties. Enviroplas PSU ENV48-NC570 belongs to high heat resistance grade and hydrolysis resistance grade materials, and enhances the characteristics of detergent resistance, oxidation resistance, chemical resistance, hydrocarbon resistance and oil resistance, providing purchasers with a choice that combines reliability and design flexibility.

01 | Analysis of material properties and characteristics

High heat resistance grade: Heat distortion temperature is approximately 171℃ (340℉), maintaining dimensional and performance stability in high-temperature environments, suitable for long-term use.

Hydrolysis resistance grade: It can maintain stable performance even in hot water or steam environments, and is particularly suitable for hot water components of medical devices and household appliances.

Detergent resistance and oxidation resistance: Cope with frequent cleaning and disinfection, reducing the risk of aging and cracking.

Chemical resistance: Resistant to erosion by acids, alkalis and various types of chemicals, it is applied in laboratory and industrial scenarios.

Hydrocarbon resistance and oil resistance: Suitable for automotive fuel parts, lubricating oil systems and energy equipment.

Design freedom: Black, transparent and clear colors are available, taking into account both functional and aesthetic requirements.

High process compatibility: Injection molding is suitable for the production of precision components, with a low shrinkage rate, reducing the risk of mold modification and scrapping.

Data support:

| Mechanical behavior | Condition | Standard | Value | Unit | |||

| Gardner Impact | 23℃ | ASTM D5420 | 440 | in·lb | |||

| Flexural Strength | ASTM D790 | 14500 | psi | ||||

| Flexural Modulus | ASTM D790 | 350000 | psi | ||||

| Izod Notch Impact | 23℃ | ASTM D256 | 1.1 | ft-lb/in | |||

| Tensile Strength | Break | ASTM D638 | 11000 | psi | |||

| Thermal | Condition | Standard | Value | Unit | |||

| HDT | Unannealed 1.80MPa | ASTM D648 | 340 | ℉ | |||

| Physical property | Condition | Standard | Value | Unit | |||

| Water Absorption | Balance | ASTM D570 | 0.30 | % | |||

| Shrinkage | Flow | ASTM D955 | 0.006~0.009 | in/in | |||

| Density | ASTM D792 | 1.23 | g/cm³ | ||||

| Melt Index | 337℃ 6.6kg | ASTM D1238 | 25 | g/10min | |||

02 | Common pain Points and Solutions for Purchasers

Pain point: Plastics are prone to deformation at high temperatures

・PSU ENV48-NC570 maintains dimensional stability in high-temperature environments.

Pain point: Medical/home appliance components frequently come into contact with hot water and detergents, resulting in a short lifespan

・Hydrolysis resistance and detergent resistance extend the service life.

Pain point: Cracking is caused by the fuel and lubricating oil environment

・Its resistance to hydrocarbons and oil ensures long-term safe operation.

Pain points: Difficulty in material selection and lack of comparison

・Juyuan offers comparisons of multiple materials such as PSU, PPSU, PC, and PBT to facilitate precise selection.

03 | Industry Application Insights

・In the medical field: Suitable for reusable sterilizable medical devices and transparent medical containers, reducing reliance on single-use plastics.

・Drinking water and household appliances: Hot water pipelines, water purification equipment, coffee machines, dishwasher components, all meet the safety requirements of the European and American markets (specific details need to be confirmed by the certified version).

・Electronics and Electrical Engineering: Electrical insulators and connectors are prominently applied in new energy vehicles and energy storage systems.

・Automobiles and Energy: Fuel and lubrication system parts, balancing durability and safety.

04 | Market trends and significance

Compliance: Meets the requirements of regulations such as RoHS and REACH, and is suitable for the medical and drinking water system market.

Sustainability: It can be sterilized and reused multiple times, extending the product's lifespan and reducing the waste of disposable plastics.

Supply chain security: In the face of fluctuations in international trade, stable PSU suppliers have become key to procurement.

05 | The supply advantage of Juyuan

・Stable supply through multiple channels, supporting large quantities and urgent orders.

・Comparison of materials from multiple brands reduces blind spots in procurement.

・Application-oriented support, combining industry trends and case studies to assist in decision-making.

・Flexible logistics solutions to meet the demands of different markets.

06 | Summary

Enviroplas PSU ENV48-NC570, with its comprehensive properties such as high heat resistance, hydrolysis resistance, detergent resistance, oxidation resistance, chemical resistance, hydrocarbon resistance and oil resistance, has become an excellent material choice for the medical, home appliance, electronic and automotive industries. For purchasers who pursue long-term stability, compliance and supply security, it is not only an engineering plastic, but also a strategic solution to reduce risks and enhance product value.

【Related Recommendations】

Anterplas PSU 905 TFE 15 | Lubricated PSU Plastic Material Learn more>

What is Polysulfone (PSU)? Material Analysis and Global Supply TrendsNew Energy Industry Learn more>

Automotive Plastic Raw Materials Procurement Guide Learn more>