PRODUCTS

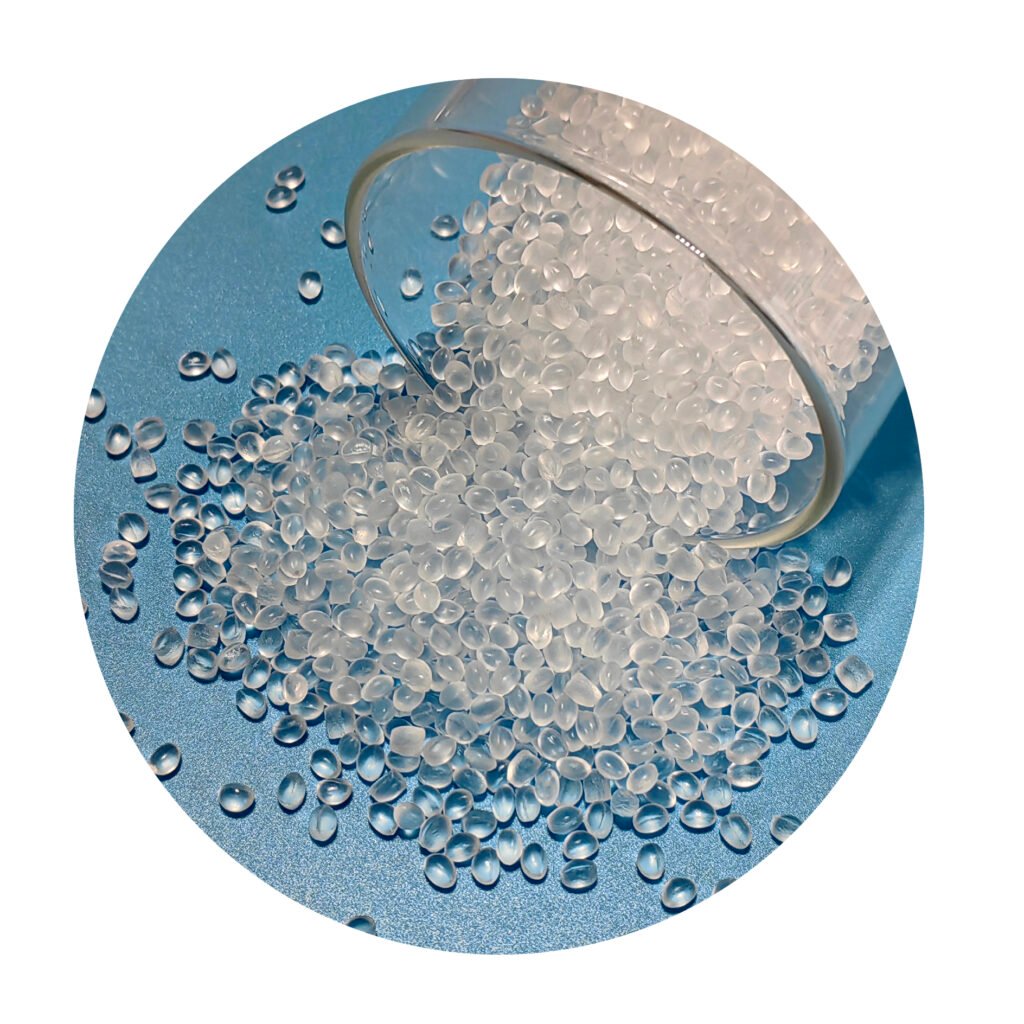

Dow POE 8400 Overview | POE Material Properties Uses and TDS

Product Struction

POE 8400: From Material Bottlenecks to Green Market Breakthroughs

In fields such as automobiles, home appliances, and consumer goods, lightweight, flexibility, durability, and environmental friendliness have become irreversible industry trends. However, traditional elastomer materials such as TPV and SEBS, although widely used, still face many technical bottlenecks in terms of processing performance, environmental protection attributes and comprehensive cost:

・TPV: Although it has good weather resistance, it is costly, has a high density, and the weight of the product is difficult to reduce.

・SEBS: It has good flexibility, but there are problems with insufficient heat resistance and long-term mechanical stability.

Therefore, seeking alternative materials with higher performance and greater economic efficiency and environmental friendliness has become a common demand for many enterprises.

01 | In line with the global trend, the technical advantages of POE material have become prominent

Dow POE 8400 material, as a new generation of ethylene-octene copolymer elastomer, fully responds to the demands of the plastic industry for "lightweight, flexible, durable and environmentally friendly" with the following characteristics:

Ultra-high fluidity: The melt index is as high as 30 g/10min, suitable for complex structure injection molding and calendering processes, improving production efficiency;

Outstanding flexibility and transparency: 1000% ultra-high elongation, excellent high definition, meeting the requirements of soft films and transparent products;

Lightweight assistance: Low specific gravity 0.870, significantly reducing the overall weight of the product;

Low-temperature impact resistance: The glass transition temperature is as low as -54°C, ensuring reliable performance in harsh environments.

Excellent environmental protection compatibility: Halogen-free, supporting green, low-carbon and sustainable material solutions.

02 | Typical downstream applications focus on sustainable development

POE material 8400 has been widely applied in:

Automotive field: Lightweight interior parts, sealing strips, and soft covering parts, contributing to the lightweighting of the entire vehicle;

Home appliance industry: Flexible sealing and impact-resistant components enhance the durability and aesthetics of products;

High-end consumer goods: Soft-touch shells and transparent functional parts, meeting the dual demands of appearance and user experience;

Environmental protection direction: Toughening agents and modified materials, promoting the green upgrade of plastic products and reducing carbon footprints.

03 | POE 8400 Material Technical Specification Sheet

| Mechanical behavior | Condition | Standard | Value | Unit | |||

| Elongation | Break 510mm/min Compression Molded | ASTM D638 | 1000 | % | |||

| Flexural Modulus | 2% Secant Compression Molded | ASTM D790 | 12.1 | MPa | |||

| Tensile Strength | Break 510mm/min Compression Molded | ASTM D638 | 3.30 | MPa | |||

| Thermal | Condition | Standard | Value | Unit | |||

| Melting Temperature | DSC 10℃/min | INTERNAL METHOD | 60.0 | ℃ | |||

| Glass Transition Temperature | INTERNAL METHOD | -54.0 | ℃ | ||||

| Vicat Softening Temperature | ASTM D1525 | 41.0 | ℃ | ||||

| Physical property | Condition | Standard | Value | Unit | |||

| Density | ASTM D792 | 0.870 | g/cm³ | ||||

| Melt Index | 190℃ 2.16kg | ASTM D1238 | 30 | g/10min | |||

| Mooney Viscosity | ML1+4 121℃ | ASTM D1646 | 2 | MU | |||

| Hardness | Condition | Standard | Value | Unit | |||

| Shore Hardness A | 1s Compression Molded | ASTM D2240 | 72 | ||||

| Shore Hardness D | 1s Compression Molded | ASTM D2240 | 20 | ||||

04 | Supply chain advantages help customers quickly capture the market

As a stable supplier of Dow POE 8400, our company provides:

✅ Spot inventory in many places, shorten delivery cycle;

✅ Full channel authorization, guarantee authenticity traceability;

✅ Batch stability, high data consistency, reduced processing fluctuation;

✅ Technical data and selection advice support to reduce customer development risk.

05 | Make a comprehensive comparison and optimize costs and efficiency

Compared with traditional TPV and SEBS, POE 8400 performs better in the following aspects:

・The POE material density is lower, and the weight reduction of the product is obvious.

・Better processing fluidity, reduced energy consumption and improved production efficiency;

・With excellent flexibility and transparency, it expands more design possibilities.

・The cost is more competitive and meets the demands of large-scale mass production.

06 | One-stop procurement service to ensure supply security

The procurement process is simple and efficient.

・Technical selection consultation to ensure the matching application of materials;

・Small-batch samples to verify processing and performance;

・Stable supply in bulk, constant inventory, and flexible delivery;

・The after-sales technical team followed up and assisted in optimizing the production process.

07 | Conclusion: POE material opens up a new situation in the green high-end market

Facing increasingly strict environmental protection regulations and market competition, choosing Dow POE 8400 material means that enterprises have stronger advantages in cost control, performance optimization and sustainable development.

Contact us immediately to obtain samples and technical materials and explore the infinite possibilities brought by material innovation together.

【Related Recommendations】

POE 5061: Versatile Polyolefin Elastomer for Flexible Films, Footwear and Plastic Modification Learn more>

POE 2300: Food-Grade POE Plastic Resin with High Elasticity for Toughening Applications Learn more>

POE 3401: High Compatibility Polyolefin Elastomer for Flexible Films and PP Modification Learn more>