PRODUCTS

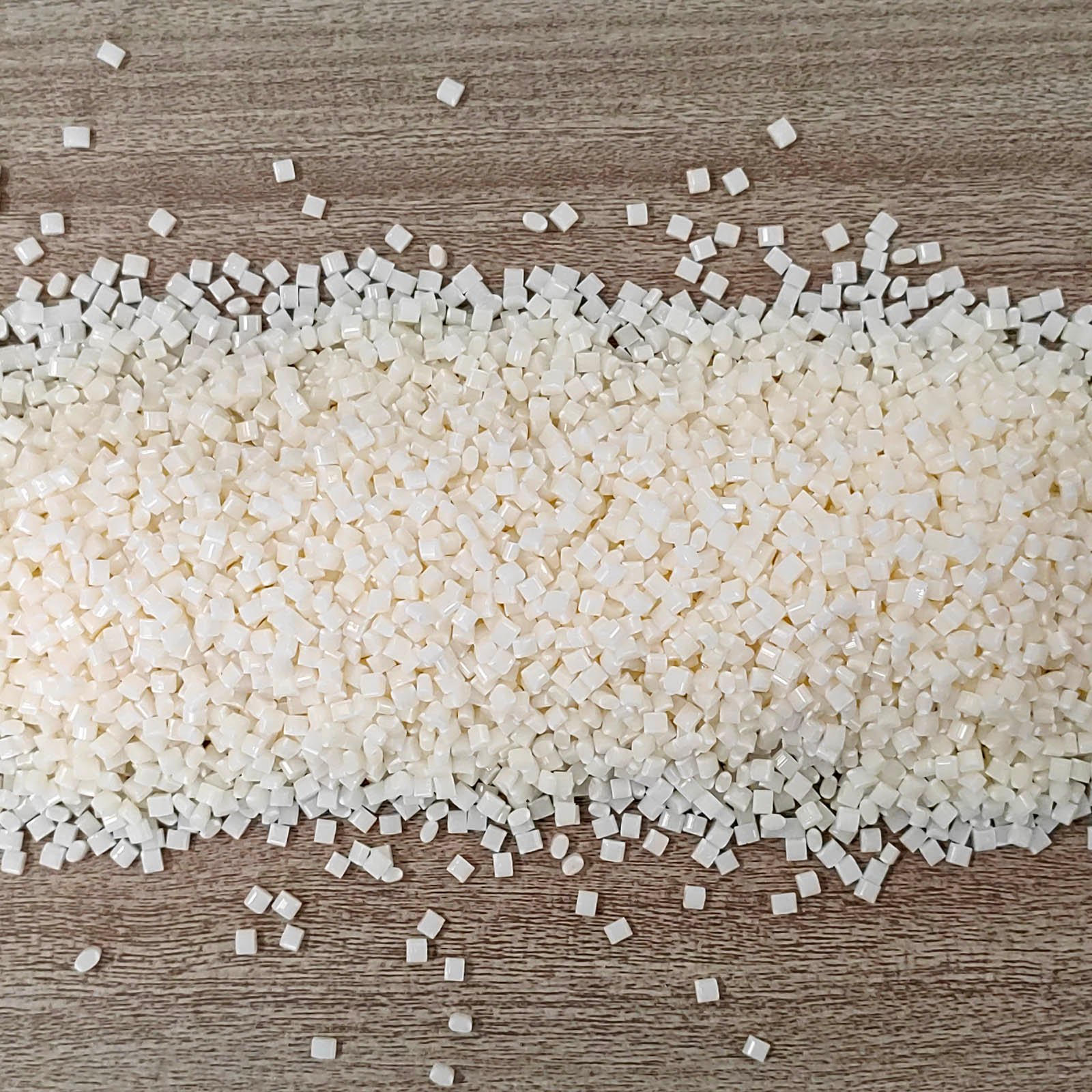

Covestro FR3000 PC ABS Plastic Material with Light Stability

Product Struction

01 | New generation PC+ABS FR3000, enabling high-standard product design

As the automotive, electrical and electronic, home appliance and other industries put forward more stringent requirements on material performance, PC ABS plastic material with excellent flame retardancy, processability and appearance performance has become the focus of the market. PC+ABS FR3000 launched by Covestro is a halogen-free flame retardant solution developed for high-performance fields, which combines high fluidity, light stability and good structural strength to meet the molding and durability requirements of complex products.

02 | PC ABS Plastic Material highlights: Performance balance beyond traditional PC ABS

PC+ABS FR3000 is based on polymer blending technology, combining the strength and heat resistance of polycarbonate (PC) with the toughness and processability of ABS resin. At the same time, by scientifically adding flame retardants and release agents, it brings the following core advantages:

✅ Halogen-free flame retardant, in line with V-0, 5VB, 5VA multi-level fire protection standards

✅ High fluidity, helping complex thin-walled structures to be efficiently injection molded

✅ Light-stable formula, improving the outdoor durability and appearance of products

✅ Excellent electrical performance, volume resistance 1E+16 Ω.cm, insulation strength up to 35 KV/mm

✅ Good impact resistance and dimensional stability, taking into account mechanical strength and reliability

Different from conventional plastics, FR3000 is positioned in high-end application fields that have synchronous requirements for flame retardancy, processing efficiency and product aesthetics, and is a typical technical pc abs plastic material representative.

03 | Application fields: Leading the material upgrade of the automotive and electronics industries

Facing the trend of intelligence and lightweight, PC+ABS FR3000 has been widely used in:

・Automotive interior and exterior trims, functional structural parts, meeting high standards of flame retardancy and strength requirements

・Electronic and electrical housings, switch panels, connectors, taking into account both safety and aesthetic design

・Smart device housings, home appliance parts, providing excellent appearance and processing efficiency

・Industrial equipment accessories, improving durability and stability

Especially in cutting-edge fields such as new energy vehicles, 5G terminals, and smart homes, PC abs plastic materials with flame retardancy, light stability, and high fluidity have become the preferred materials for design engineers.

04 | Technical Data That Reflects Real Performance

| UL | Condition | Standard | Value | Unit | |||

| CTI | IEC 60112 | 2 | PLC | ||||

| GWFI | 0.75mm | IEC 60695-2-12 | 900 | °C | |||

| GWIT | 3.0mm | IEC 60695-2-13 | 800 | °C | |||

| HAI | All Color 0.75mm | UL 746A | 0 | PLC | |||

| HAI | All Color 3.0mm | UL 746A | 0 | PLC | |||

| HVTR | UL 746A | 1 | PLC | ||||

| HWI | All Color 0.75mm | UL 746A | 3 | PLC | |||

| HWI | All Color 3.0mm | UL 746A | 1 | PLC | |||

| RTI | Elec All Color 1.0mm | UL 746B | 90 | °C | |||

| RTI | Str All Color 1.5mm | UL 746B | 85 | °C | |||

| RTI | Str All Color 2.0mm | UL 746B | 85 | °C | |||

| RTI | Str All Color 3.0mm | UL 746B | 90 | °C | |||

| Volume Resistivity | ASTM D257 | 1E+16 | Ω.cm | ||||

| Ball pressure | IEC 60695-10-2 | 88 | °C | ||||

| Dielectric Strength | ASTM D149 | 33 | KV/mm | ||||

| Arc Resistance | ASTM D495 | 5 | PLC | ||||

| Flame Rating | All Color 2.0mm | UL94 | V-0 5VB | ||||

| Flame Rating | All Color 3.0mm | UL94 | V-0 5VA | ||||

| Mechanical behavior | Condition | Standard | Value | Unit | |||

| Elongation | Yield 50mm/min | ISO 527 | 3.5 | % | |||

| Elongation | Break 50mm/min | ISO 527 | 40 | % | |||

| Izod Un-notch Impact | 23°C | ISO 180 | NB | kJ/m² | |||

| Izod Notch Impact | 23°C | ISO 180 | 35 | kJ/m² | |||

| Izod Notch Impact | -30°C | ISO 180 | 10 | kJ/m² | |||

| Tensile Strength | Break 50mm/min | ISO 527 | 45 | MPa | |||

| Tensile Strength | Yield 50mm/min | ISO 527 | 60 | MPa | |||

| Tensile Modulus | 1.0mm/min | ISO 527 | 2700 | MPa | |||

| Thermal | Condition | Standard | Value | Unit | |||

| HDT | 0.45MPa | ISO 75 | 92 | °C | |||

| HDT | 1.8MPa | ISO 75 | 82 | °C | |||

| CLE | Flow 23~55°C | ISO 11359 | 7.6E-5 | cm/cm/°C | |||

| CLE | xFlow 23~55°C | ISO 11359 | 8E-5 | cm/cm/°C | |||

| Vicat Softening Temperature | 50°C/hr 50N | ISO 306 | 95 | °C | |||

| Vicat Softening Temperature | 120°C/hr 50N | ISO 306 | 97 | °C | |||

| Physical property | Condition | Standard | Value | Unit | |||

| Water Absorption | 23°C | ISO 62 | 0.5 | % | |||

| Water Absorption | 23°C 50RH balance | ISO 62 | 0.2 | % | |||

| Shrinkage | Flow 150x105x3mm 240°C Mold temperature:80°C | ISO 2577 | 0.5~0.7 | % | |||

| Shrinkage | xFlow 150x105x3mm 240°C Mold temperature:80°C | ISO 2577 | 0.5~0.7 | % | |||

| Density | ISO 1183 | 1.18 | g/cm³ | ||||

| Melt Viscosity | 260°C 1000sˉ1 | ISO 11443 | 160 | Pa·s | |||

| Melt Index | 240°C 5kg | ISO 1133 | 24 | cm³/10min | |||

| Electrical properties | Condition | Standard | Value | Unit | |||

| CTI | Solution A | IEC 60112 | 350 | V | |||

| Dielectric Constant | 1MHz | IEC 60250 | 3.1 | ||||

| Dielectric Constant | 100Hz | IEC 60250 | 3.2 | ||||

| Volume Resistivity | IEC 60093 | 1E+16 | Ω.cm | ||||

| Dielectric Strength | 1.0mm | IEC 60243 | 35 | KV/mm | |||

| Dissipation Factor | 1MHz | IEC 60250 | 0.006 | ||||

| Dissipation Factor | 100Hz | IEC 60250 | 0.005 | ||||

| Surface Resistivity | IEC 60093 | 1E16 | Ω | ||||

| Flammability | Condition | Standard | Value | Unit | |||

| Flame Rating | All Color 1.5mm | UL94 | V-0 | ||||

| Flame Rating | All Color 2.0mm | UL94 | V-0 5VB | ||||

| Flame Rating | All Color 3.0mm | UL94 | V-0 5VA | ||||

05 | Analysis of technical advantages: How does FR3000 meet stringent standards?

PC+ABS FR3000 has passed a number of international standard tests to fully verify its comprehensive performance:

✔ UL94 fire rating up to 5VA, ensuring flame retardant performance in extreme environments

✔ GWIT up to 800°C, GWFI up to 960°C, improving heat resistance and safety factor

✔ Excellent electrical resistance and dimensional stability, suitable for high-precision structural parts

✔ High-flow formula (melt index 24 cm³/10min), optimizes the injection molding process of complex products

✔ Vicat softening temperature up to 97°C, ensuring the heat resistance and stability of products

These characteristics enable FR3000 to achieve a balance between electrical safety, mechanical properties and processing efficiency, making it an ideal material choice for high-demand products.

06 | Trader Advantages: Providing Standard and Customized PC ABS Solutions

As a professional plastic raw material supplier, we not only provide Covestro PC+ABS FR3000 standard specifications, but also provide personalized modification and supporting services according to different customer needs:

🔧 Customizable high impact resistance, chemical resistance, reinforcement, UV resistance and other multifunctional solutions

📊 Support flexible combinations of different colors, fluidity, and environmental protection levels

⏩ Quick response, technical support and sample development are carried out simultaneously to reduce trial and error costs

🌍 Global supply chain network to ensure stable delivery and product compliance

Compared with single brand channels, we focus on flexible, efficient and practical pc abs plastic material overall solutions to help companies speed up product development, upgrade performance and enhance market competitiveness.

07 | Conclusion: Choose FR3000 to create safer and more efficient innovative products

PC+ABS FR3000 is not only a single plastic particle, but also a comprehensive material platform that integrates flame retardancy, safety, appearance and processing advantages. Whether it is new energy vehicles, smart electronics, industrial equipment, or home appliances, Covestro FR3000 helps engineering design break through traditional limitations with its high fluidity and light stability.

If you need reliable performance, stable supply, and customizable pc abs plastic material, please contact us to obtain professional technical information and personalized modification solutions to jointly create high-performance products that meet future trends.

08 | Related Products: Explore More High-Performance PC+ABS Plastic Material Options

In addition to FR3000, we offer a full range of pc abs plastic material solutions to meet diverse performance and processing needs:

| Brand | Material Name | Product Model | Density | Melt Flow Index | Key Data Summary | Description |

| Covestro | PC+ABS | T85 XF | 1.14 g/cm³ | 19 cm³/10min | Flame Rating: HB Melt Flow Index: 19 cm³/10min Notched Impact: 48 kJ/m² Heat Deflection Temp: 126°C | Compliance: UL Material Features: High Flow • Non-reinforced |

| Covestro | PC+ABS | T65 XF | 1.13 g/cm³ | 18 cm³/10min | Flame Rating: HB Melt Flow Index: 18 cm³/10min Notched Impact: 48 kJ/m² Heat Deflection Temp: 122°C | Compliance: UL Material Features: High Flow • Non-reinforced |

Beyond standard grades, we also provide customized modification services, including enhanced weatherability, chemical resistance, reinforcement, or UV stability, helping you optimize product performance while reducing development risks.

【Related Recommendations】

What is PC ABS? Rethinking the Value of PC ABS Plastic Material Learn more>

LG GN5001RF: High Flow PC ABS Material for Electronics and Automotive Applications Learn more>

PC+ABS FR3010 Material:Halogen-Free Flame Retardant for Automotive & Electronics Learn more>