PRODUCTS

BASF Ultrason® S 3010 | Heat-Resistant Polysulfone for Labware

Product Struction

What is Ultrason® S 3010

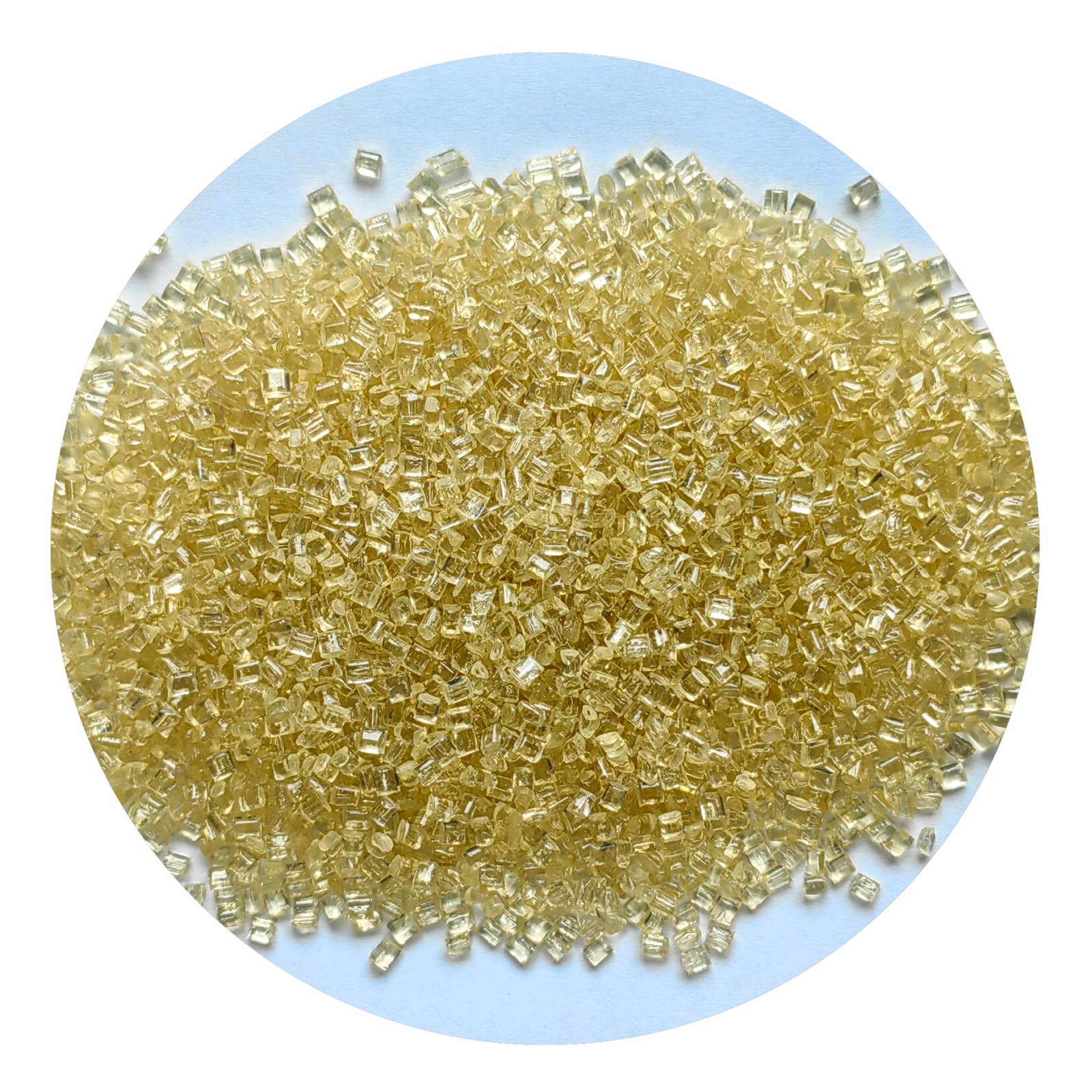

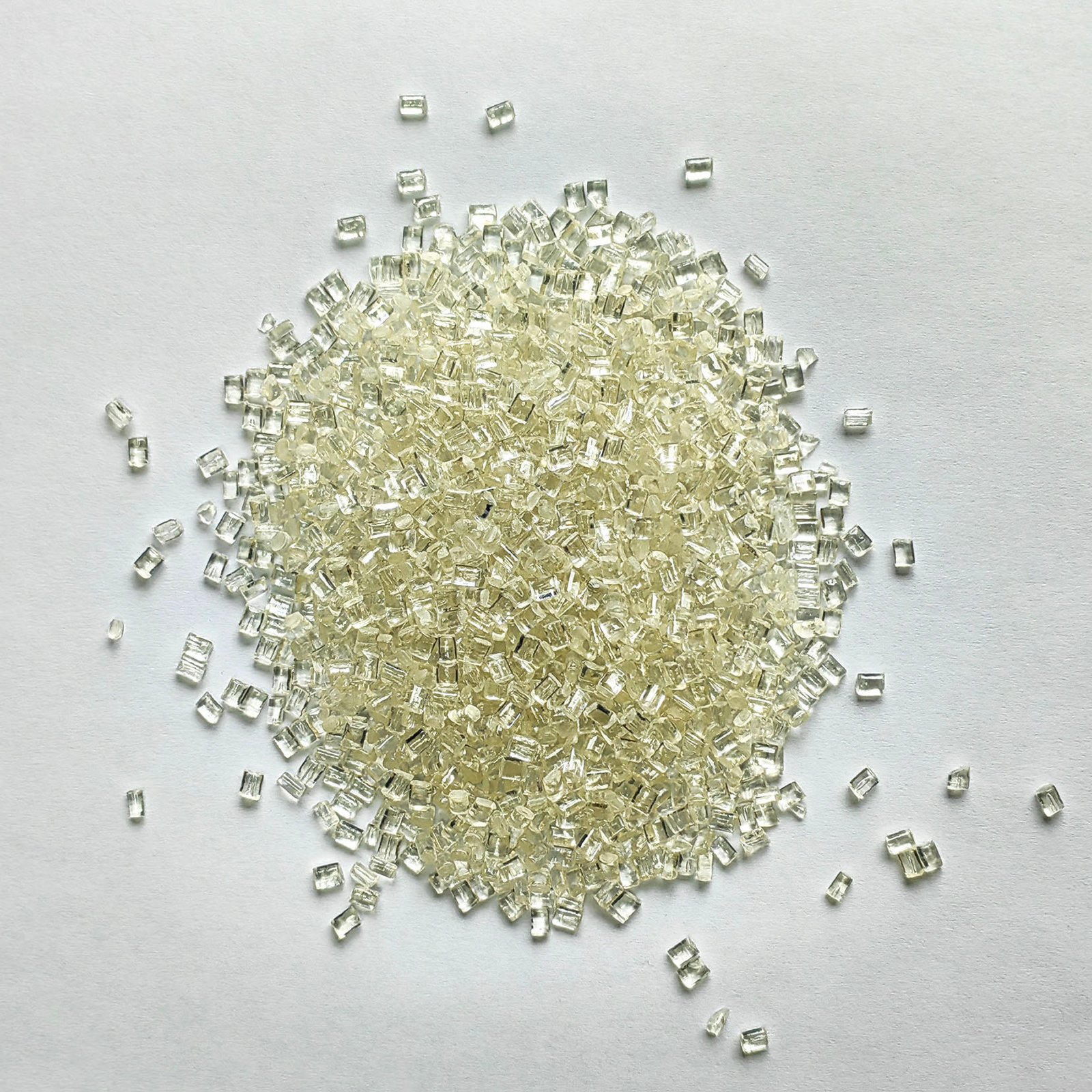

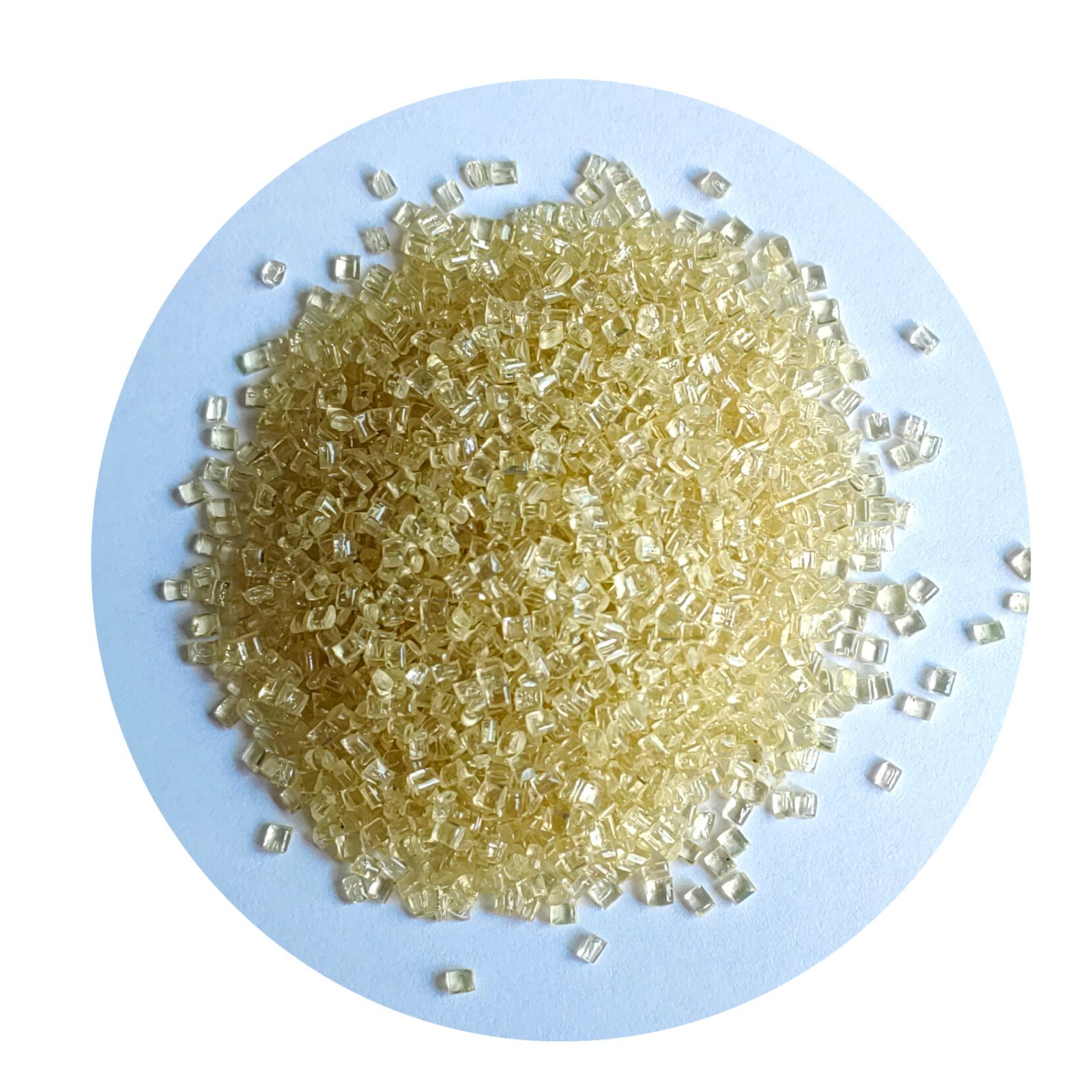

BASF Ultrason® S 3010 (PSU 3010) is a high-viscosity Polysulfone particle, specially designed for injection molding processing. It combines chemical resistance, stress crack resistance and toughness, and is suitable for application scenarios that require long-term reliability, such as laboratory equipment and household items. For manufacturers pursuing stable performance and processing efficiency, ultrason s 3010 offers a balanced and sustainable solution.

01 | Material highlights and procurement value

From the perspective of purchasers, the advantages of Ultrason® S 3010 lie not only in its physical parameters but also in its ability to address the pain points in practical applications:

Chemical resistance and stress crack resistance

・In laboratory equipment and chemical environments, materials are prone to erosion by cleaning agents, acids, alkalis or organic solvents. The chemical resistance and stress crack resistance of PSU 3010 ensure that the product can maintain structural integrity during long-term use and will not fail prematurely due to stress concentration.

・Solve the problem: Reduce product scrapping and after-sales costs caused by cracking.

Good mechanical strength and toughness

・The tensile strength is 75 MPa, and the impact toughness can still maintain 6.0 kJ/m² at a low temperature (-30°C), demonstrating the material's stability under extreme conditions.

・Problem-solving: Ensure that the products remain safe and reliable in the event of drops, impacts or cold environments, and reduce customer complaints.

Excellent thermal stability

・The heat distortion temperature (1.8MPa) reaches 177°C, and the long-term service temperature can be maintained at 155°C.

・Solution: Experimental equipment and household appliances suitable for high-temperature environments, avoiding precision failure caused by thermal deformation.

Electrical insulation and flame retardancy

・The volume resistance is as high as 1E15 Ω·cm, the insulation strength is 37 kV/mm, and the flame retardant grade is UL94 HB.

・Solution: Provide stable insulation protection for electrical components and laboratory instruments to enhance usage safety.

Processing adaptability

・The melt index (360°C, 10kg) is 40 cm³/10min, with excellent fluidity and suitable for precision injection molding.

・Solve the problem: Enhance production efficiency and reduce the defective rate during the processing.

02 | BASF Ultrason® S 3010 Data Sheet

| Electrical properties | Condition | Standard | Value | Unit | |||

| CTI | IEC 60112 | 125 | V | ||||

| Dielectric | Strength | IEC 60243 | 37 | KV/mm | |||

| Dielectric | Constant 100Hz | IEC 60250 | 3.1 | ||||

| Dielectric | Constant | IEC 60250 | 3.1 | ||||

| Dissipation | Factor 100Hz | IEC 60250 | 8 | ||||

| Dissipation | Factor 1MHz | IEC 60250 | 64 | ||||

| Surface | Resistivity | IEC 60093 | 1E+15 | Ω | |||

| Volume | Resistivity | IEC 60093 | 1E+13 | Ω.cm | |||

| Flammability | Condition | Standard | Value | Unit | |||

| Flame | Rating All Color 0.75mm | UL94 | HB | ||||

| Flame | Rating All Color 1.5mm | UL94 | HB | ||||

| Flame | Rating All Color 3.0mm | UL94 | HB | ||||

| Hardness | Condition | Standard | Value | Unit | |||

| Ball | Indentation Hardness | ISO 2039 | 135 | MPa | |||

| Mechanical behavior | Condition | Standard | Value | Unit | |||

| Charpy | Notch Impact -30°C | ISO 179 | 6 | kJ/m² | |||

| Charpy | Notch Impact 23°C | ISO 179 | 5.5 | kJ/m² | |||

| Charpy | Un-notch Impact -30°C | ISO 179 | NB | kJ/m² | |||

| Charpy | Un-notch Impact 23°C | ISO 179 | NB | kJ/m² | |||

| Elongation | Yield 23°C | ISO 527 | 6 | % | |||

| Izod | Notch Impact -30°C | ISO 180 | 6 | kJ/m² | |||

| Izod | Notch Impact 23°C | ISO 180 | 5.5 | kJ/m² | |||

| Tensile | Modulus 23°C | ISO 527 | 2550 | MPa | |||

| Tensile | Strength Yield 23°C | ISO 527 | 75 | MPa | |||

| Physical property | Condition | Standard | Value | Unit | |||

| Density | ISO 1183 | 1.23 | g/cm³ | ||||

| Melt | Index 360°C 10kg | ISO 1133 | 40 | cm³/10min | |||

| Shrinkage | Flow | ISO 294 | 0.7 | % | |||

| Shrinkage | xFlow | ISO 294 | 0.74 | % | |||

| Water | Absorption 50RH | ISO 62 | 0.3 | % | |||

| Water | Absorption Saturation | ISO 62 | 0.8 | % | |||

| Thermal | Condition | Standard | Value | Unit | |||

| CLE | Flow | INTERNAL METHOD | 5.3E-5 | cm/cm/°C | |||

| HDT | 1.8MPa | ISO 75 | 177 | °C | |||

| UL | Condition | Standard | Value | Unit | |||

| Arc | Resistance | ASTM D495 | 5 | PLC | |||

| Comparative | Tracking Index | IEC 60112 | 3 | PLC | |||

| Dielectric | Strength | ASTM D149 | 32 | KV/mm | |||

| Dimensional | Stability | UL746 | 0.0 | % | |||

| HAI | ALL 0.75mm | UL 746A | 4 | PLC | |||

| HAI | ALL 1.5mm | UL 746A | 4 | PLC | |||

| HAI | ALL 3.0mm | UL 746A | 0 | PLC | |||

| HVTR | UL 746A | 3 | PLC | ||||

| HWI | ALL 0.75mm | UL 746A | 4 | PLC | |||

| HWI | ALL 1.5mm | UL 746A | 3 | PLC | |||

| HWI | ALL 3.0mm | UL 746A | 2 | PLC | |||

| RTI | Elec ALL 0.75mm | UL 746B | 155 | °C | |||

| RTI | Elec ALL 1.5mm | UL 746B | 155 | °C | |||

| RTI | Elec ALL 3.0mm | UL 746B | 155 | °C | |||

| RTI | Imp ALL 0.75mm | UL 746B | 130 | °C | |||

| RTI | Imp ALL 1.5mm | UL 746B | 130 | °C | |||

| RTI | Imp ALL 3.0mm | UL 746B | 130 | °C | |||

| RTI | Str ALL 1.5mm | UL 746B | 155 | °C | |||

| RTI | Str ALL 3.0mm | UL 746B | 155 | °C | |||

| UL | FlameRating ALL 0.75mm | UL94 | HB | ||||

| UL | FlameRating ALL 1.5mm | UL94 | HB | ||||

| UL | FlameRating ALL 3.0mm | UL94 | HB | ||||

| Volume | Resistivity | ASTM D257 | 1E+12 | Ω.cm | |||

03 | Technical process and processing compatibility

Ultrason® S 3010, as a high-viscosity PSU, is specially optimized for injection molding processes and features the following characteristics:

・Forming temperature range: It is recommended to carry out melting processing at 340-380° C. The mold temperature is suggested to be maintained at 160-180°C to ensure dimensional stability.

・Screw design suggestion: High-temperature resistant screw materials should be adopted to prevent material degradation at high temperatures.

・Mold compatibility: Suitable for forming thick-walled parts and transparent utensils, with a processing shrinkage rate of only 0.7-0.74%, which helps maintain part accuracy.

・Secondary Processability: Machining, bonding, and thermal welding are possible, facilitating post-processing in various application scenarios.

These process parameters enable buyers to better control yield and cost during mass production.

04 | Market Trends and Industry Dynamics

According to BASF's latest market news, the Ultrason® product line has seen significant growth in recent years in medical and laboratory equipment, heat-resistant consumer goods, and power tool components. In particular, in 2024, BASF announced the expansion of PSU production capacity in Germany and Asia to meet the rapidly growing demand for high-temperature-resistant transparent plastics in the downstream medical and electrical appliance industries.

・Medical and Laboratory: It can replace some glassware, reducing the risk of breakage.

・Home Appliances and Kitchenware: It is more heat-resistant and washable, meeting consumer trends for durability and safety.

・Electrical and Electronics: It meets the dual requirements of electrical insulation and high-temperature resistance.

For buyers, this means greater material supply stability and reduced future procurement risks.

05 | Customer Feedback

・A laboratory equipment manufacturer: Choosing Ultrason® S 3010 instead of traditional glass has reduced product scrap rates by 40% and significantly improved transportation safety.

・A customer in the home appliance industry stated: Using PSU 3010 for kitchen appliance housings solves the problem of plastic brittle cracking caused by long-term cleaning, extending the product lifecycle.

・An electronic device customer stated: Using it on electrical insulation components effectively reduces the risk of failure due to high temperatures or stress cracking.

These practical application feedbacks further validate the value of PSU 3010 in various industries.

06 | FAQ - Frequently Asked Questions for Buyers

Q1: What is the difference between Ultrason® S 3010 and S 2010?

A1: S 3010 is a high-viscosity grade, better suited for injection molding thick-walled and high-strength components; S 2010 has a lower viscosity and better flowability, making it suitable for complex, thin-walled products.

Q2: Is this material suitable for use with metal parts?

A2: Yes. PSU 3010's dimensional stability and heat resistance enable it to work well with metal components, and it is often used in medical devices and electrical appliances.

Q3: How does Juyuan ensure timely delivery of procurement? A3: We have a stable supply channel with BASF and have logistics partners in multiple regions, supporting both bulk purchases and flexible small-batch delivery.

Q4: Do you provide technical selection and cost optimization advice?

A4: Juyuan provides material performance comparisons, alternative material recommendations, and application case studies to help customers reduce costs while maintaining stable product performance.

07 | Similar Recommendations

In addition to Ultrason® S 3010, we also offer the following related materials:

| Manufacturer | Product Grade | Density | Melt Flow Index | Tensile Strength | Elongation | Shrinkage | Melting Temperature | Tensile Modulus | Heat Deflection Temperature | Notched Izod Impact | Linear Expansion Coefficient |

| BASF | 3010 NAT | 1.23 g/cm³ | 40 cm³/10min | 75 MPa | 6% | 0.70% | 330~390 °C | 2550 MPa | 177 °C | 5.5 kJ/m² | 5.3E-5 cm/cm/°C |

| BASF | 3010 MR | 1.23 g/cm³ | 45 cm³/10min | 75 MPa | 5.80% | 0.70% | — | 2600 MPa | 177 °C | 5.5 kJ/m² | 5.3E-5 cm/cm/°C |

| BASF | 3010 MR UN | 1.23 g/cm³ | 45 cm³/10min | 75 MPa | 5.80% | 0.70% | 330~390 °C | 2600 MPa | 177 °C | 5.5 kJ/m² | 5.3E-5 cm/cm/°C |

08 | Why choose Juyuan as your supplier?

In the global plastic raw material trade, selecting a reliable supply partner is as important as choosing the right material. Juyuan offers the following advantages:

・24 years of experience in international plastic raw material trade, familiarity with cross-border procurement processes, and the ability to quickly connect with buyers' needs.

・Flexible Supply Chain: Stable channels ensure timely delivery of BASF Ultrason® S 3010 and other engineering plastics.

・Professional Technical Support: Beyond providing materials, we also assist customers with application selection and cost optimization.

・Global Customer Base: We serve a wide range of industries, including electronics, electrical, medical, and consumer goods, with extensive experience.

【Related Recommendations】

A Complete Guide to China’s Major Plastic Raw Material Procurement Hubs & Markets Learn more>

BASF PSU 2010 | High Flowability PSU Polysulfone for Household Learn more>

Americhem PSU-GF30HF High-flow PSU Resin for Injection Molding Learn more>