PRODUCTS

BASF polyamide 6 B27 E Full Guide | Applications and Data Sheet

Product Struction

What is Polyamide 6

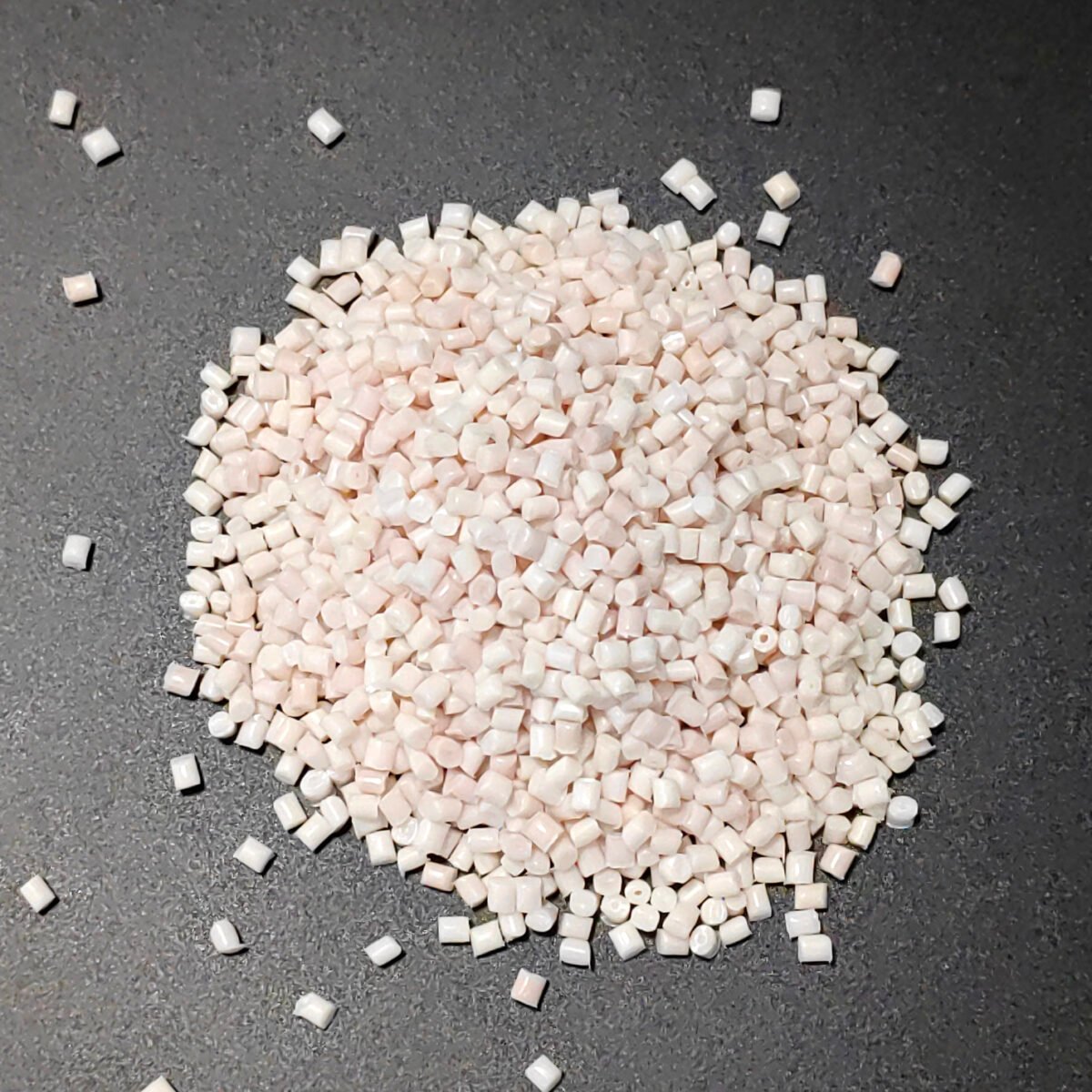

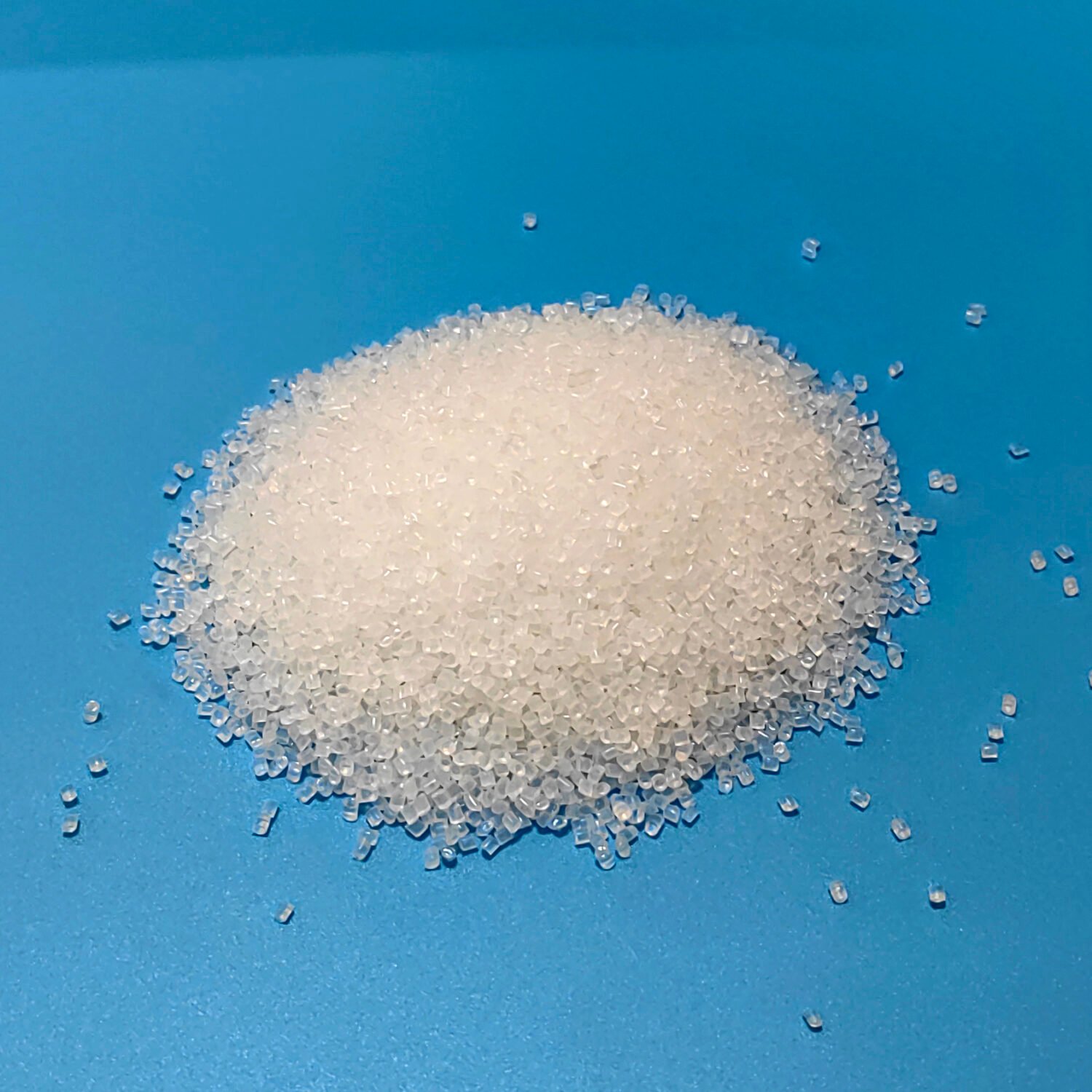

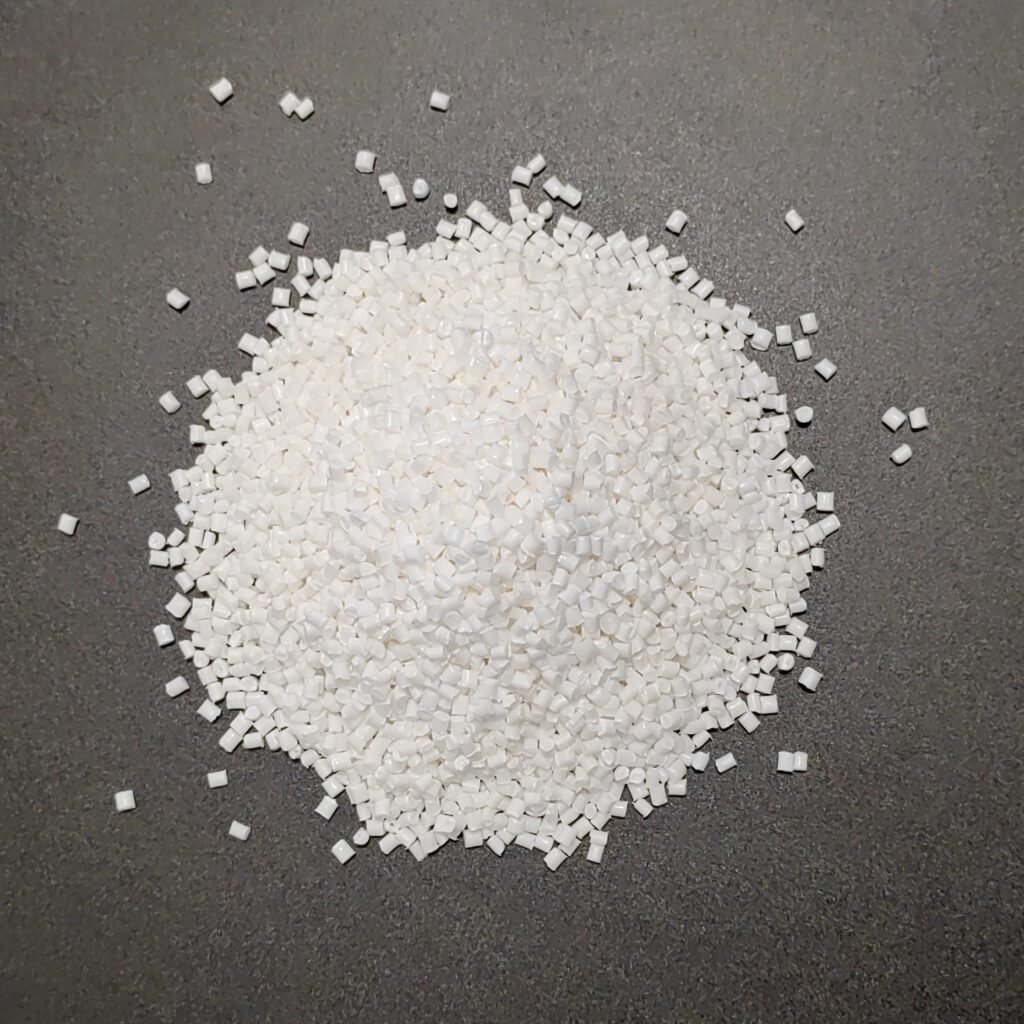

BASF polyamide 6 B27 E is an unreinforced polyamide 6 (PA6) resin with excellent electrical insulation, thermal stability and good processability designed for injection moulding. While maintaining the general performance advantages of the polyamide family, the material has a higher volume resistivity and contact withstand voltage (CTI 600V), making it suitable for structural components, electrical housings, connectors, and other industrial applications with high insulation requirements.

01 | Technical Analysis: From Molecular Structure to Application Performance

Molecular structure and melting point

PA6 is a linear polyamide formed by ring-opening polymerization of caprolactam, with strong hydrogen bonding between the molecular chains. B27 E has typical polyamide 6 melt characteristics, with a melting point of about 220°C, indicating a moderate degree of crystallinity, making it suitable for processing with standard injection moulding equipment. This property provides a good basis for thermal stability and flow control during the moulding process.

Water absorption behaviour in relation to mechanical and electrical properties

Water absorption is common in polyamide materials, but the water absorption of B27 E at 50% relative humidity is controlled at 2.2%, which is better than that of unmodified PA6. Water absorption affects the dimensional stability and insulating properties of nylon, so this value means that it can still maintain high structural and electrical stability in humid or outdoor environments.

Electrical Safety Benefits of High CTI Values

The material has a CTI value of 600V, which belongs to the higher class of electrical safety, indicating that it can effectively resist the phenomenon of tracking and reduce the risk of breakdown in areas of high humidity or voltage concentration, and is suitable for appliance housings, electrical components and connectors with high insulation requirements.

Formability and process compatibility

polyamide 6 B27 E has a stable melt flow temperature and does not decompose easily in the injection moulding temperature zone, making it suitable for medium shear rate processing. It is recommended to be processed under dry conditions to avoid bubbles, silver streaks and other apparent defects caused by moisture absorption, and the moulded products have better surface quality and dimensional accuracy.

02 | Polyamide 6 B27 E Application Suggestion

BASF polyamide 6 B27 E is suitable for a variety of areas requiring medium strength and toughness, while taking into account the processing efficiency, for example:

Structural parts for industrial equipment: gears, slides, connectors, and other parts with medium strength requirements;

Electrical housings and insulated parts: thanks to its high CTI and stable electrical properties;

Automotive non-exterior parts: e.g. fan blades, brackets, small connecting seats;

Internal structural support parts for consumer electronics.

The material can be glass-fibre reinforced, flame-retardant modified or lubrication reinforced as required to meet higher functional requirements.

03 | Polyamide 6 B27 E Processing Suggestions

polyamide 6 B27 E is suitable for standard injection moulding equipment. It is recommended that the processing temperature be controlled between 230°C and 260°C. To control the impact of water absorption on performance and product size, it is recommended to dry thoroughly before use. The recommended drying conditions are 80°C for more than 4 hours.

In terms of mould design, the flow channels and exhaust systems should be reasonably set up to reduce the risk of material hydrolysis and improve the appearance of the products.

04 | Polyamide 6 B27 E Datasheet

| Thermal | Condition | Standard | Value | Unit |

| Melting Temperature | ISO 11357 | 220 | °C | |

| Physical property | Condition | Standard | Value | Unit |

| Water Absorption | 23°C 24hr | ISO 62 | 8.5 | % |

| Water Absorption | 23°C 50RH | ISO 62 | 2.2 | % |

| Density | ISO 1183 | 1.12 | g/cm³ | |

| Electrical properties | Condition | Standard | Value | Unit |

| CTI | IEC 60112 | 600 | V |

05 | Business support and supply capacity

As a professional distributor of engineering plastics, we can provide stable supply support for BASF PA6 B27 E resin to global customers, including:

Original package granules, traceable batches;

Chinese and English TDS and UL certification data;

Specification samples and technical selection suggestions;

Flexible logistics solutions and export services.

【Related Recommendations】

PET 850H 80: High-Strength Polyethylene Terephthalate for Premium Packaging Learn more>

UBE PA6 1013B: Nylon 6 for Electrical and Structural Components Learn more>

PET 8050:Halogen-Free Flame Retardant PET Resin for Structural and Electrical Parts Learn more>