PRODUCTS

Applications of Polypropylene PP K7926 Lightweight High-Performance Material

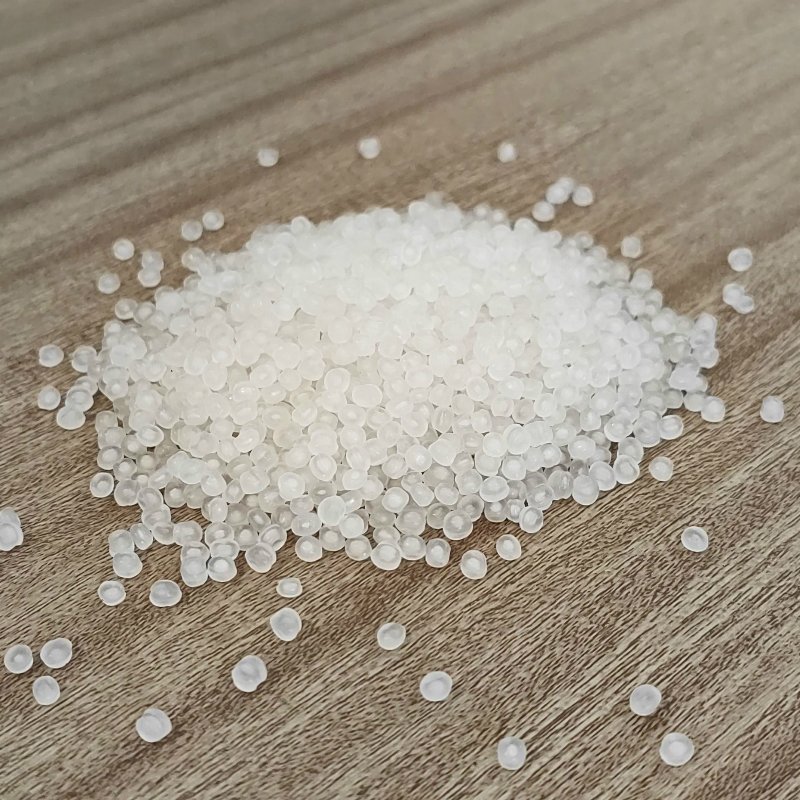

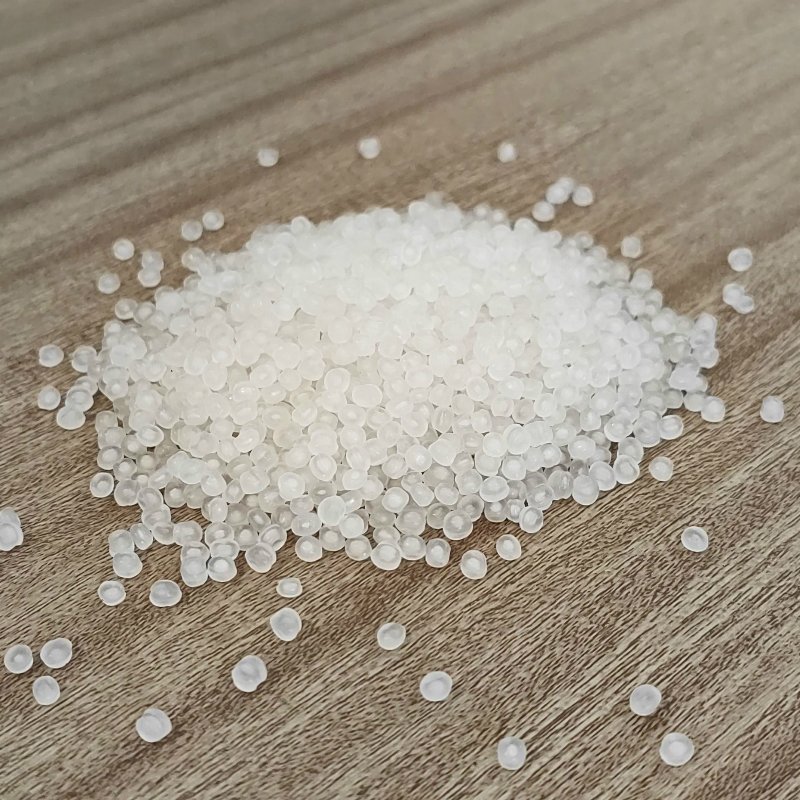

Product Struction

Polypropylene (PP), as a widely used thermoplastic polymer in modern society, has attracted widespread attention for its unique properties and wide range of applications. PP K7926, as a typical representative among them, not only demonstrates the basic characteristics of polypropylene but also stands out in specific performance, making it indispensable in many industries.

Polypropylene is produced by the polymerization of propylene monomers, which generates long-chain polymers with good chemical resistance. This material can resist the erosion of most solvents, acids, and bases, and has a low water absorption rate. These characteristics make polypropylene an ideal choice for medical devices, food packaging, and other fields that require high chemical stability and safety of materials.

In addition to chemical stability, polypropylene also possesses excellent physical properties. Its density is low, only 0.90-0.91 g/cm³, which means that polypropylene products are lightweight and can effectively reduce costs during production and transportation. At the same time, polypropylene has good fatigue resistance and impact resistance, making it an ideal choice for automotive parts and construction materials.

In terms of electrical insulation and transparency, polypropylene also shows its advantages. These characteristics make polypropylene widely used in electronic devices and household items. Its good weather resistance and durability further expand the range of applications of polypropylene, allowing it to be used outdoors for a long time without easy aging.

Of course, the performance of polypropylene is also influenced by factors such as molecular weight and molecular weight distribution, crystallinity, type and proportion of comonomers, and tacticity. These factors work together to determine the final properties of polypropylene. For example, isotactic polypropylene, due to the special arrangement of methyl groups, has higher crystallinity and hardness, which makes it surpass atactic polypropylene and polyethylene in resistance to creep.