PRODUCTS

Applications and Performance Analysis of Polypropylene PP HJ4012

Product Struction

Polypropylene (PP), as a widely recognized and applied thermoplastic polymer, its unique physical and chemical properties make it an ideal material for various industrial and daily life products. In particular, the PP HJ4012 model, with its excellent physical properties and processing characteristics, has become the preferred material in many manufacturing sectors.

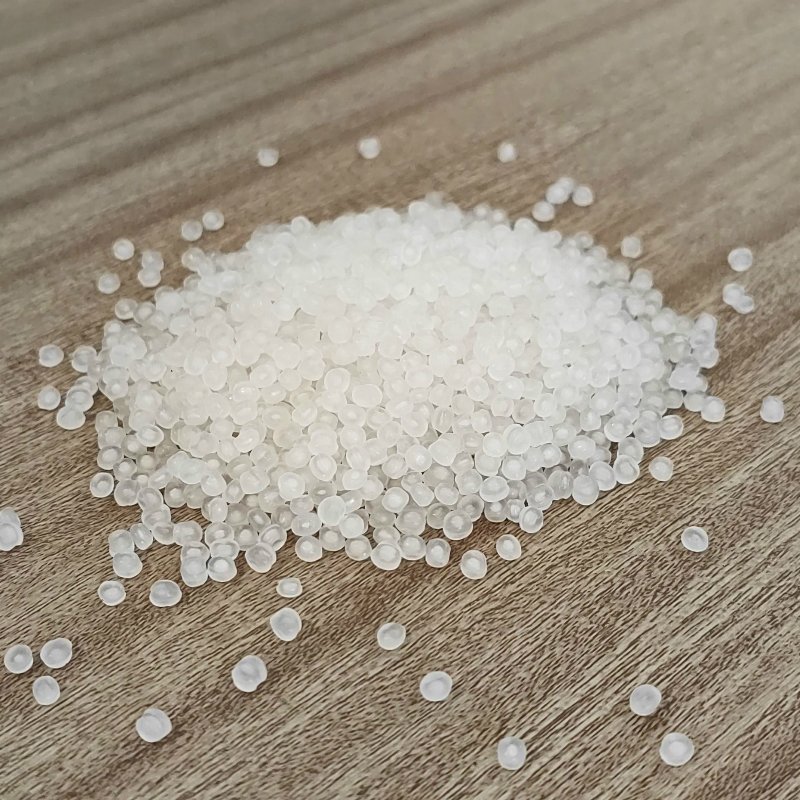

PP HJ4012 is a homopolymer polypropylene with a full-color granular form, mainly processed through injection molding. This material has a flammability rating of HB, positioned for injection molding and heat resistance grades. It can provide scratch resistance, high impact, and high rigidity performance while maintaining long-term heat resistance and good processability. Its application range is extremely wide, from automotive parts to electronic and electrical applications, to household appliance casings and home goods, making PP HJ4012 an ideal choice for these products due to its superior performance.

In terms of technical parameters, PP HJ4012 exhibits excellent mechanical and thermal performance. According to ASTM D638 standards, its tensile strength reaches 420 kg/cm², with an elongation at break of 50%. In terms of flexural modulus, according to ASTM D790 standards, the material can reach 21,000 kg/cm², showing very high rigidity. The cantilever beam notch impact test result is 4 kg-cm/cm, proving its excellent impact performance. Additionally, the heat distortion temperature, melting temperature, and Vicat softening temperature are 140°C, 168°C, and 156°C, respectively, showing good heat resistance. The material's specific gravity is 0.91 g/cm³, with a melt flow index of 14 g/10min, a shrinkage rate between 1.4~1.8%, and a Rockwell hardness (R scale) of 110, further validating its reliability and stability as an engineering plastic.

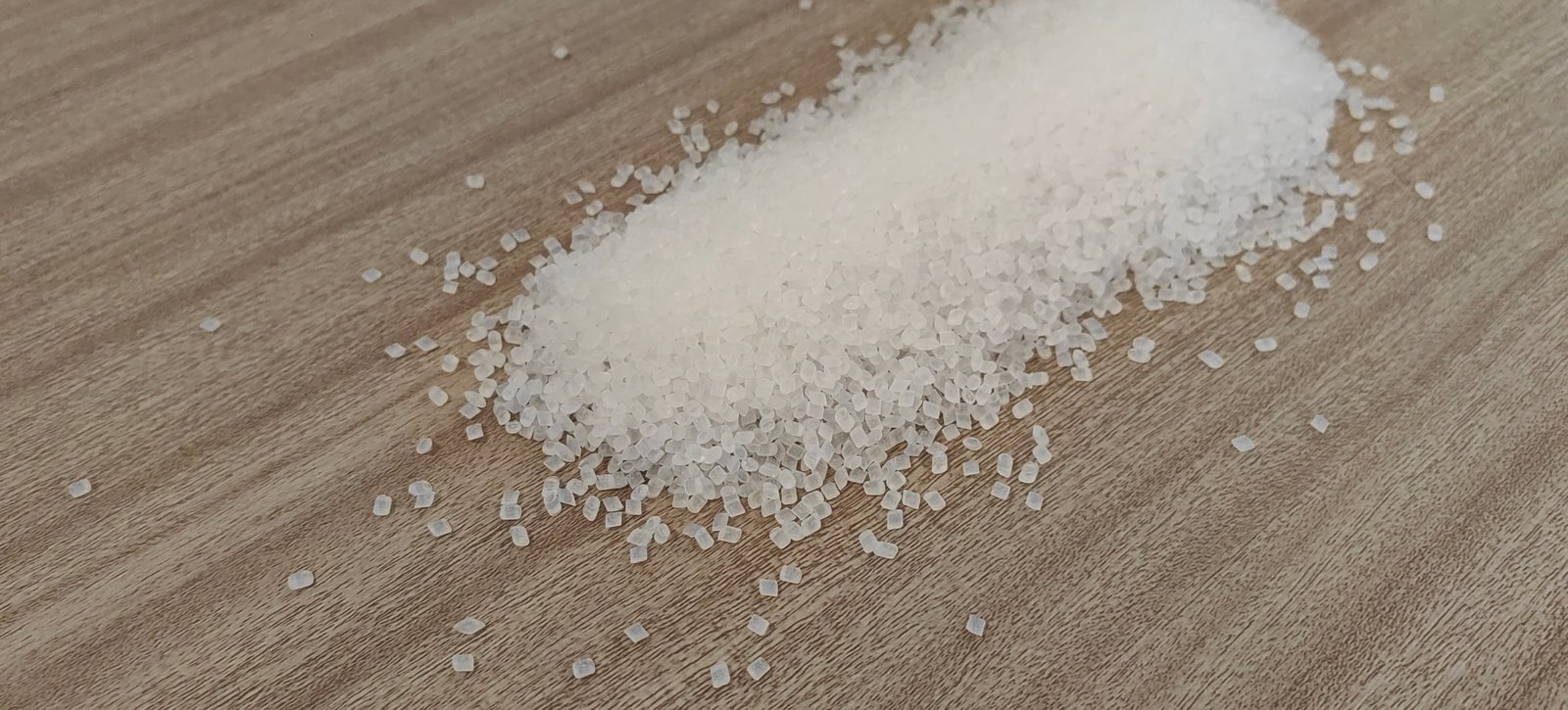

Compared with other plastic materials, such as polyethylene (PE), the main structural difference of polypropylene (PP) is the presence of side chains. The methyl side chains in PP not only improve the material's mechanical properties and heat resistance but also allow for further adjustment and optimization of its performance by controlling molecular weight, molecular weight distribution, crystallinity, and the type and proportion of copolymers. For example, isotactic polypropylene, due to the orientation of methyl groups on one side of the carbon main chain, shows higher crystallinity and hardness, making it better in creep resistance compared to atactic polypropylene and polyethylene.