Introduction: Identifying Demands and Insights into Market Opportunities

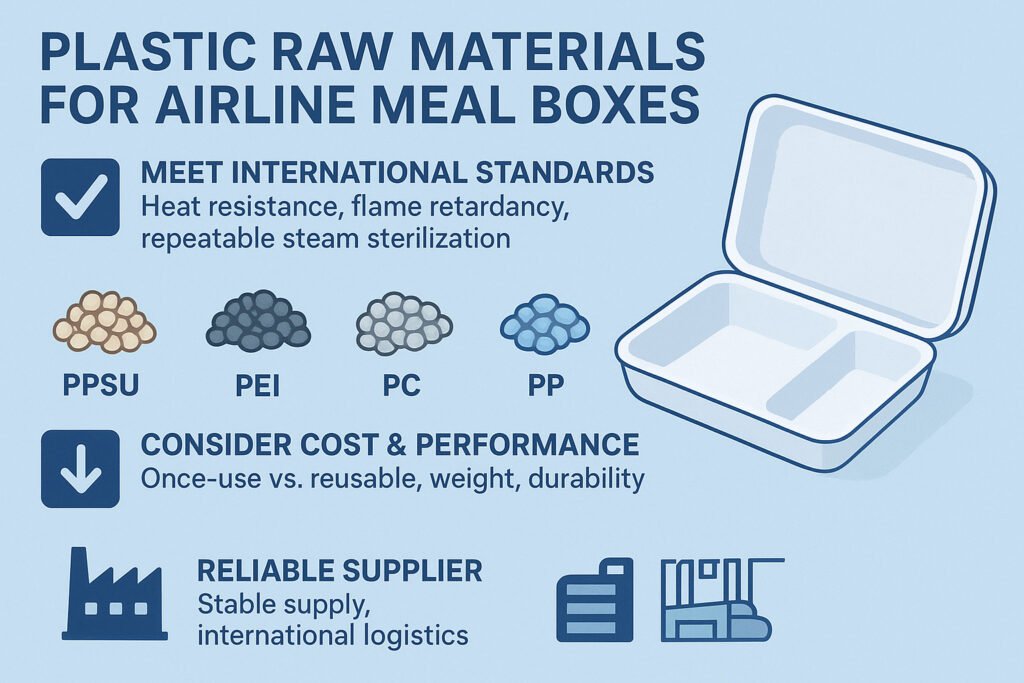

With the advancement of airline catering, the selection of materials for airplasne food trays is no longer simply a matter of "usability"; it now encompasses multiple requirements, including food safety, lightweighting, high-temperature resistance, and environmental compliance. For buyers, finding the right plastic raw material pellets and selecting a reliable supplier are key to mitigating risk and ensuring delivery.

In a client case study, Juyuan successfully solved a material challenge for an airline food tray manufacturer: the client specifically required the selected raw materials to withstand autoclaving (121–134°C) or short-term oven heating to approximately 200°C to meet aviation cleaning and high-temperature sterilization standards. This demonstrates that the airline food tray market not only has high-volume demand for disposable PP and PET, but is also increasingly moving towards high-performance and sustainable materials.

1. Industry Standards Required for airplasne food tray Materials

・Food Safety Regulations and HACCP Control Systems: The airline catering industry generally adheres to the International Airline Services Association (IFSA)'s "World Food Safety Guidelines for Airline Catering" and establishes critical control points based on HACCP principles to ensure food safety throughout the entire process.

・High-temperature sterilization requirements: To prevent bacteria and pathogens, tableware materials must withstand high-pressure steam sterilization (commonly used for cleaning reusable tableware). Some products also require short-term high-temperature oven testing, with extreme tests reaching around 200°C.

・Structural and sealing stability: The high altitude and turbulent environment of flights require food containers to have excellent pressure resistance, sealing, and consistency, especially to remain stable and leak-proof in alternating hot and cold environments.

2. Core requirements for plastic raw materials in airline food trays

・Food safety compliance: They must comply with food contact standards such as FDA, EU, and LFGB.

・Heat resistance: Disposable food container must withstand hot meals; reusable lunch box must withstand repeated high-temperature cleaning and steam sterilization (such as PPSU).

・Lightweighting: Every kilogram of weight saved in the aviation industry reduces fuel consumption, making lightweight materials crucial.

・Environmental protection and sustainability: Biodegradable materials such as PLA and PBAT have attracted attention, but are still in the pilot and exploratory stages and have not yet fully met the comprehensive requirements of airline catering in terms of heat resistance and cost.

・Supply Chain Reliability: Airline catering requires long-term, stable, and high-volume supply, and the raw material supply must be guaranteed.

3. Common Challenges Faced by Buyers When Sourcing Raw Materials

・Difficulty determining whether a material is suitable for lunch box applications (e.g., which is more suitable: PPSU, PP, or PET?)

・Unclear certification requirements, leading to concerns about food contact safety compliance.

・International Sourcing Risks: Uncertainty about price, lead times, and shipping stability.

・Lack of Professional Support: Suppliers are expected to provide technical advice rather than simply sell materials.

4. Customer Case Study: How PPSU Raw Materials Meet Extreme Temperature Requirements

Material Selection and Technical Basis

We recommended PPSU (polyphenylsulfone) pellets to our client based on the following key performance indicators:

・High glass transition temperature (Tg) of approximately 220°C, maintaining rigidity and shape stability even during short-term heating.

・High heat deflection temperature (HDT) of approximately 207°C, maintaining resistance to softening under load.

・PPSU maintained mechanical properties and dimensional stability after over 100 cycles of steam sterilization at 121–134°C.

Validation Testing Process

Juyuan assisted the client in performing the following tests:

・High-Temperature Oven Testing: Injection molded parts were briefly heated to 200°C (extreme operating conditions validation) to confirm the absence of warping, cracking, or performance degradation.

・High-Pressure Steam Sterilization Testing: Multiple cycles of 121–134°C simulated steam environments were performed, ensuring structural integrity and consistent appearance.

Conclusion

The PPSU material not only met the client's requirements for high-temperature environments but also demonstrated reliable performance, fully meeting the requirements for airplasne food tray use.

5. Juyuan's Core Values

Through this case study, Juyuan demonstrated its unique advantages in the airline food tray material market:

・Precise Material Recommendation: After understanding industry needs, we quickly identified PPSU materials that met high-temperature sterilization and heating requirements.

・Authoritative Performance Data Support: References data from material suppliers and industry literature to provide Tg, HDT, and sterilization cycle stability indicators.

・Testing Support and Trusted Verification: Assists buyers with high-temperature and steam sterilization validation, ensuring risk-free material selection.

・Certification and Supply Assurance: Provides food contact safety certification documentation, combined with a stable international supply chain to ensure high-volume supply and consistent quality.

6. Trend Outlook: Future Market Opportunities

・High-Temperature Durable Lunch Boxes: Repeated sterilization and reuse are becoming a key direction in aviation environmental protection strategies.

・Lightweight and heat-resistant materials go hand in hand: PP and PET continue to dominate the disposable lunch box market, but demand for high-temperature resistant materials such as PPSU is growing rapidly.

・Technical Services as the Core of Competitiveness: Suppliers that can provide material selection evaluation, testing, verification, and certification support will more easily gain the trust of buyers.

7. Conclusion and Call for Action

When selecting plastic raw materials, airplasne food tray manufacturers require materials that meet food safety, high-temperature sterilization resistance, structural stability, and environmental performance. Juyuan provides a complete solution for PPSU material selection, testing, verification, and supply services.

If you are looking for food-grade materials that meet airline meal tray standards, please contact Juyuan. We will recommend a suitable solution and provide professional support throughout the process.