PRODUCTS

Metallocene mLLDPE LL7810A injection molding grade plastic raw material

Product Struction

Metallocene Linear Low-Density Polyethylene Introduction

Metallocene Linear Low-Density Polyethylene (mLLDPE) LL7810A is a high-performance polymer material manufactured by PTT Global Chemical. This material is refined through copolymerization with hexene, using a metallocene catalyst at its core. Its unique molecular structure imparts outstanding mechanical, optical, and thermal properties, making it a significant upgrade over traditional linear low-density polyethylene (LLDPE).

LL7810A exhibits remarkable flexibility and strength, with a tensile strength of up to 50 MPa and an elongation at break ranging from 700% to 800%. In film applications, its tear strength is particularly notable, demonstrating balanced tear resistance in both the machine and transverse directions. Additionally, the material excels in optical performance, boasting a gloss level of 35 and a haze of just 13%, resulting in films with excellent transparency and visual appeal.

The material has a melting temperature of 122°C and a low heat-sealing temperature, ensuring high processing efficiency and broad applicability. With a density of 0.918 g/cm³ and a melt index of 1.0 g/10min, LL7810A is highly suitable for various processing techniques such as blow molding, extrusion, and cast film production. It can be used to produce films with uniform thickness as well as sheets and pipes in diverse forms.

In practical applications, LL7810A is widely used in food packaging, pharmaceutical packaging, and industrial heavy-duty packaging films. It is particularly advantageous in the production of frozen and stretch films. Additionally, it demonstrates stable performance in construction materials and agricultural films, meeting durability requirements while offering processing convenience and environmental adaptability.

As a highly specialized material, metallocene linear low-density polyethylene LL7810A delivers exceptional performance, providing innovative possibilities for the packaging industry and related fields. It not only showcases the advancement of metallocene catalytic technology but also opens new application prospects for thinner, stronger, and more transparent film products.

Metallocene Linear Low-Density Polyethylene Datasheet

| Blow Molding | Condition | Standard | Value | Unit | |||

| Die | Temperature | 170~190 | °C | ||||

| Melt | Temperature | 160~180 | °C | ||||

| Extrusion molding | Condition | Standard | Value | Unit | |||

| Die | Temperature | 170~190 | °C | ||||

| Melt | Temperature | 160~180 | °C | ||||

| Mechanical behavior | Condition | Standard | Value | Unit | |||

| Elongation | Flow Break 25μm Blown Film | ASTM D882 | 700 | % | |||

| Elongation | xFlow Break 25μm Blown Film | ASTM D882 | 800 | % | |||

| Falling | Weight Impact Strength 25μm Blown Film | ASTM D1709 | 423 | g | |||

| Tearing | Strength Flow 25μm Blown Film | ASTM D1922 | 300 | g | |||

| Tearing | Strength xFlow 25μm Blown Film | ASTM D1922 | 400 | g | |||

| Tensile | Modulus Flow 25μm 1% Secant Blown Film | ASTM D882 | 200 | MPa | |||

| Tensile | Modulus xFlow 25μm 1% Secant Blown Film | ASTM D882 | 230 | MPa | |||

| Tensile | Strength Flow Break 25μm Blown Film | ASTM D882 | 50 | MPa | |||

| Tensile | Strength xFlow Break 25μm Blown Film | ASTM D882 | 50 | MPa | |||

| Optical performance | Condition | Standard | Value | Unit | |||

| Gloss | 45° 25μm Blown Film | ASTM D2457 | 35 | ||||

| Haze | 25μm Blown Film | ASTM D1003 | 13 | % | |||

| Physical property | Condition | Standard | Value | Unit | |||

| Density | ASTM D792 | 0.918 | g/cm³ | ||||

| Melt | Index 190°C 2.16kg | ASTM D1238 | 1.0 | g/10min | |||

| Thermal | Condition | Standard | Value | Unit | |||

| Melting | Temperature | ASTM D3418 | 122 | °C | |||

| Vicat | Softening Temperature | ASTM D1525 | 106 | °C | |||

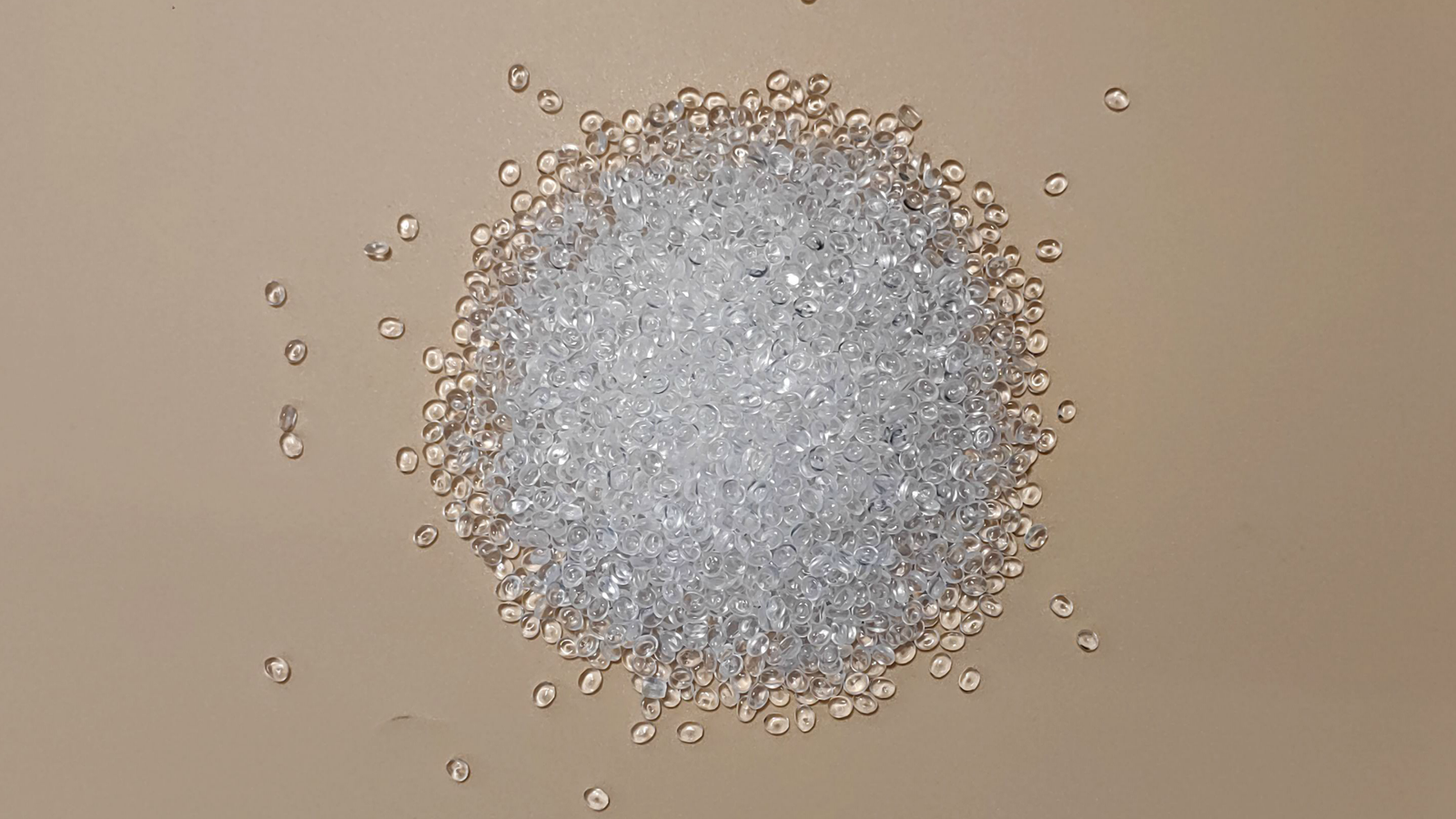

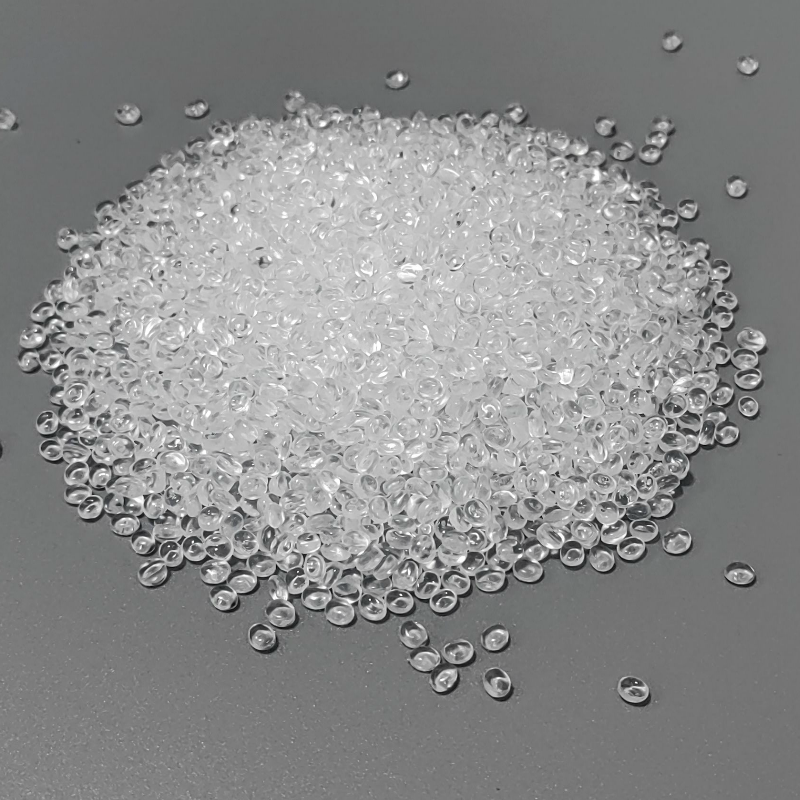

Metallocene Linear Low-Density Polyethylene Display

Want to learn more? Get the TDS and request a free sample—contact us today!

【Related Recommendations】

mLLDPE D173: High-Clarity, Tough Film-Grade Mlldpe Resin for Packaging Learn more>

mLLDPE LL7835A injection grade Heavy duty film application plastic raw material Learn more>

What material is ABS? Learn more>