PRODUCTS

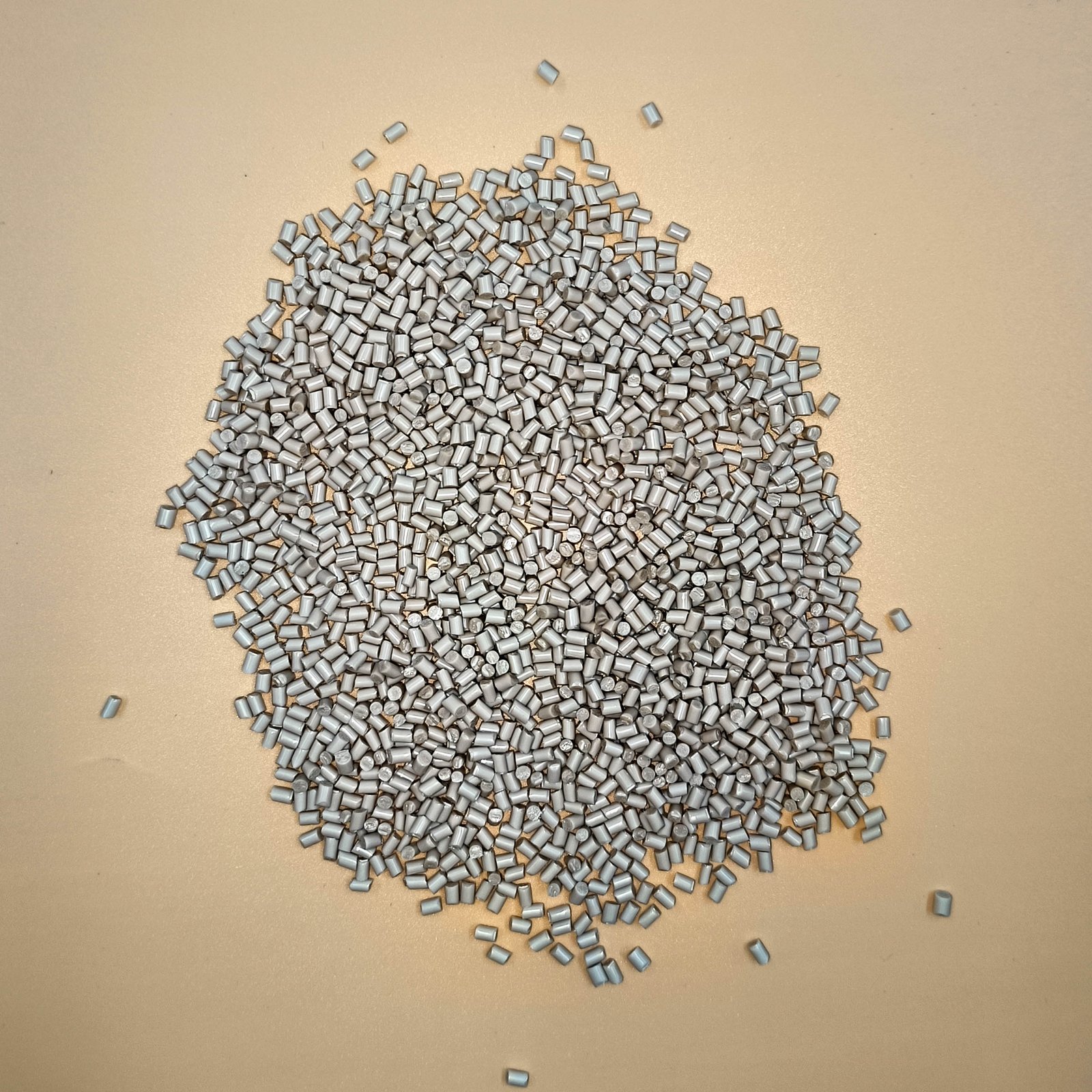

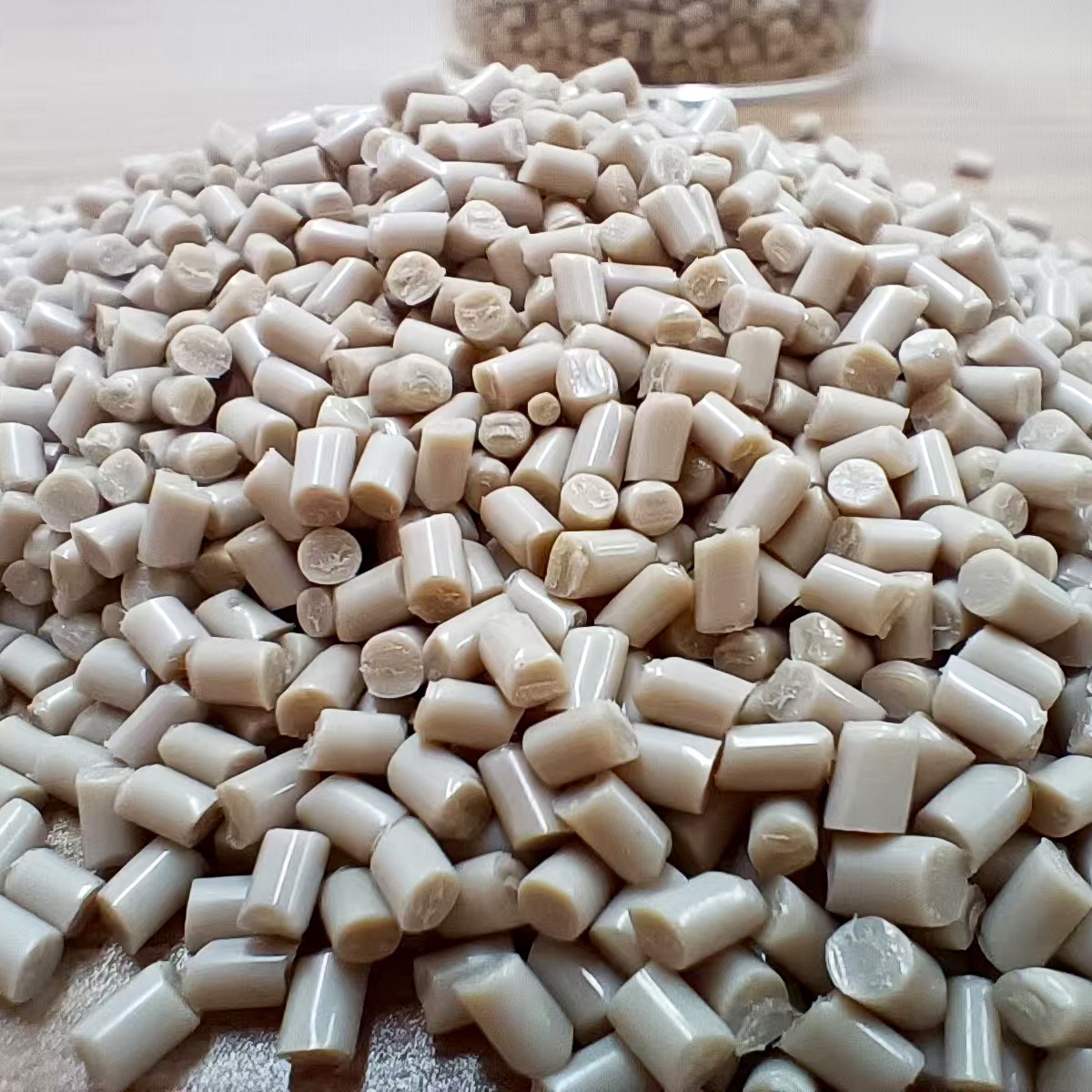

PEEK-OPTIMA® LT1 Medical-Grade Polyether Ether Ketone PEEK

Product Struction

What is Polyether Ether Ketone PEEK

Invibio® PEEK-Optima ® LT1 is a polyether ether ketone PEEK material specifically developed for medical implants and nursing devices.

It combines a pure chemical structure, stable biological inertness and excellent mechanical toughness. After decades of clinical verification, it has become a reliable alternative metal material recognized in the medical industry.

01 | Core Material Properties

Biocompatibility and low extract characteristics

PEEK-OPTIMA® LT1 strictly controls the content of organic residues and ionic impurities during the polymerization and purification process to ensure low extract and low residue.

The material has been certified by ISO 10993 series biological assessment and can be in long-term contact with human tissues without causing inflammation or degradation reactions.

High purity and chemical stability

This polyether ether ketone PEEK resin can resist the erosion of body fluids, drugs and cleaning agents for a long time. Even under repeated sterilization or high-temperature conditions, its molecular structure can still remain stable and no soluble substances are precipitated.

Multiple sterilization compatibility

PEEK-OPTIMA® LT1 supports the following sterilization methods:

・Ethylene oxide (EO)

・Gamma-ray irradiation

・High-temperature steam (Autoclave)

・Plasma and Dry Heat

Its molecular stability ensures that its mechanical properties remain unchanged after hundreds of sterilization cycles, making it an ideal material for highly reusable medical components.

Excellent mechanical and physical properties

PEEK-OPTIMA® LT1 combines high strength, good ductility and low moisture absorption.

This performance balance enables it to maintain structural stability even when subjected to impact, bending or long-term loads, making it particularly suitable for load-bearing implants.

02 | PEEK-OPTIMA® LT1 Data Sheet

| Mechanical behavior | Condition | Standard | Value | Unit | |||

| Elongation | 23℃ | ISO 527 | 40 | % | |||

| Flexural Strength | 23℃ | ASTM D790 | 165 | MPa | |||

| Flexural Modulus | 23℃ | ISO 178 | 4100 | MPa | |||

| Izod Notch Impact | 23℃ | ISO 180 | 8 | kJ/m² | |||

| Tensile Strength | 23℃ | ISO 527 | 100 | MPa | |||

| Thermal | Condition | Standard | Value | Unit | |||

| Melting Temperature | 340 | ℃ | |||||

| CLE | Flow | ASTM D696 | 4.7E-5 | cm/cm/℃ | |||

| Physical property | Condition | Standard | Value | Unit | |||

| Water Absorption | 23℃ 24hr | ISO 62 | 0.5 | % | |||

| Shrinkage | Flow | ISO 294 | 1.2 | % | |||

| Hardness | Condition | Standard | Value | Unit | |||

| Rockwell Hardness | M(Scale) | ASTM D785 | 99 | ||||

03 | Trends in Medical Applications and Alternatives

This material is widely used in:

・Spinal and orthopedic implants: fusion cages, intervertebral support blocks, fixation plates

・Dental restoration structures: bases, dental implant connectors

・Surgical instrument components: Structural parts, sleeves and handles that require repeated sterilization

Compared with metallic materials, polyether ether ketone PEEK has the following alternative advantages:

・The elastic modulus is close to that of human bones, reducing the stress shielding effect

・Non-conductive and non-heat-conductive, enhancing patient comfort

・No metal artifacts, facilitating postoperative CT/MRI imaging

04 | Flexibility in processing and design

・Invibio PEEK-OPTIMA® LT1 is suitable for injection molding, extrusion and calendering.

・Under the conditions of precision molds, complex-structured parts can be achieved, with stable thermal stability and flow performance, ensuring the accuracy and surface quality of the parts.

・Its low shrinkage rate and low hygroscopicity make it suitable for multi-cavity molds and long-cycle mass production.

05 | Supply and Service Advantages of Juyuan

As a global trader of polyether ether ketone PEEK materials, Juyuan provides medical manufacturers with:

・Original factory channel supply: Long-term stock or customized supply of Invibio medical-grade raw materials

・Technical selection support: Assist customers in evaluating PEEK grades and processing compatibility

・Regulatory and compliance assistance: Provide material data packages and medical registration material support

・Customized service: Supports small-batch sample, color or formula customization

Juyuan not only provides materials but also offers complete solutions oriented towards the demands of medical manufacturing.

06 | Frequently Asked Questions (FAQ)

Q1: Has PEEK-OPTIMA® LT1 passed the medical-grade certification?

A: Yes, the material complies with the ISO 10993 biocompatibility standard, has a long-term clinical application record, and can be used for implant-level applications.

Q2: How many sterilization cycles can it withstand?

A: It can be stably maintained for over 100 cycles under steam, EO or γ sterilization conditions without significant deterioration in mechanical and surface properties.

Q3: Can it be modified according to requirements?

A: Invibio LT1 is usually used in pure unfilled form, but Juyuan can provide modified polyether ether ketone PEEK, such as reinforced grade, lubricating grade or conductive grade, for device components.

Q4: Do the materials comply with medical regulations in Europe and America?

A: Invibio PEEK-OPTIMA® LT1 has established a complete regulatory database to meet medical registration requirements such as FDA and EU MDR.

Q5: What is the supply cycle and batch size provided by Juyuan?

A: Regular spot goods can be delivered within 7 to 15 days. For large orders, materials can be prepared in advance according to the annual purchasing plan.

07 | Similar Recommendations

The following are recommended other models of the Invibio PEEK-OPTIMA® series

| Product Model | Density | Tensile Strength | Elongation | Shrinkage | Melting Temperature | Rockwell Hardness | Izod Impact | Flexural Modulus | Coefficient of Linear Expansion | Flexural Strength |

| LT3 | — | 108 MPa | 25% | 1.30% | 340 °C | 99 | 5 kJ/m² | 4200 MPa | 4.7E-5 cm/cm/°C | 170 MPa |

| Unfilled | — | 100 MPa | 20% | — | — | — | 8 kJ/m² | 4000 MPa | — | 170 MPa |

| Granular | 1.29 g/cm³ | 100 MPa | 20% | 1.20% | 340 °C | 99 | 63 kJ/m² | 4000 MPa | 4.7E-5 cm/cm/°C | 170 MPa |

| Image Contrast (Low radiopacity) | — | 95 MPa | 20% | — | — | — | 7 kJ/m² | 3800 MPa | — | 150 MPa |

| Image Contrast (High radiopacity) | — | 90 MPa | 15% | — | — | — | 8 kJ/m² | 4500 MPa | — | 150 MPa |

08 | Conclusion

Invibio PEEK-Optima ® LT1 has established its authoritative position among medical-grade polyether ether ketone PEEK materials with four major advantages: "high purity, low extract, biocompatibility, and multi-sterilization compatibility".

Through Juyuan's global supply and technical support, more medical manufacturers are building safe and sustainable medical innovation solutions with PEEK materials.

【Related Recommendations】

KetaSpire® KT-880 BK 95: Medical Polyether Ether Ketone PEEK Learn more>

LUVOCOM® 3F PEEK CF 9676 BK: Chemical-Resistant PEEK Polymers Learn more>

Glove Materials: PVC, NBR, and TPE Cost Comparison Learn more>