PRODUCTS

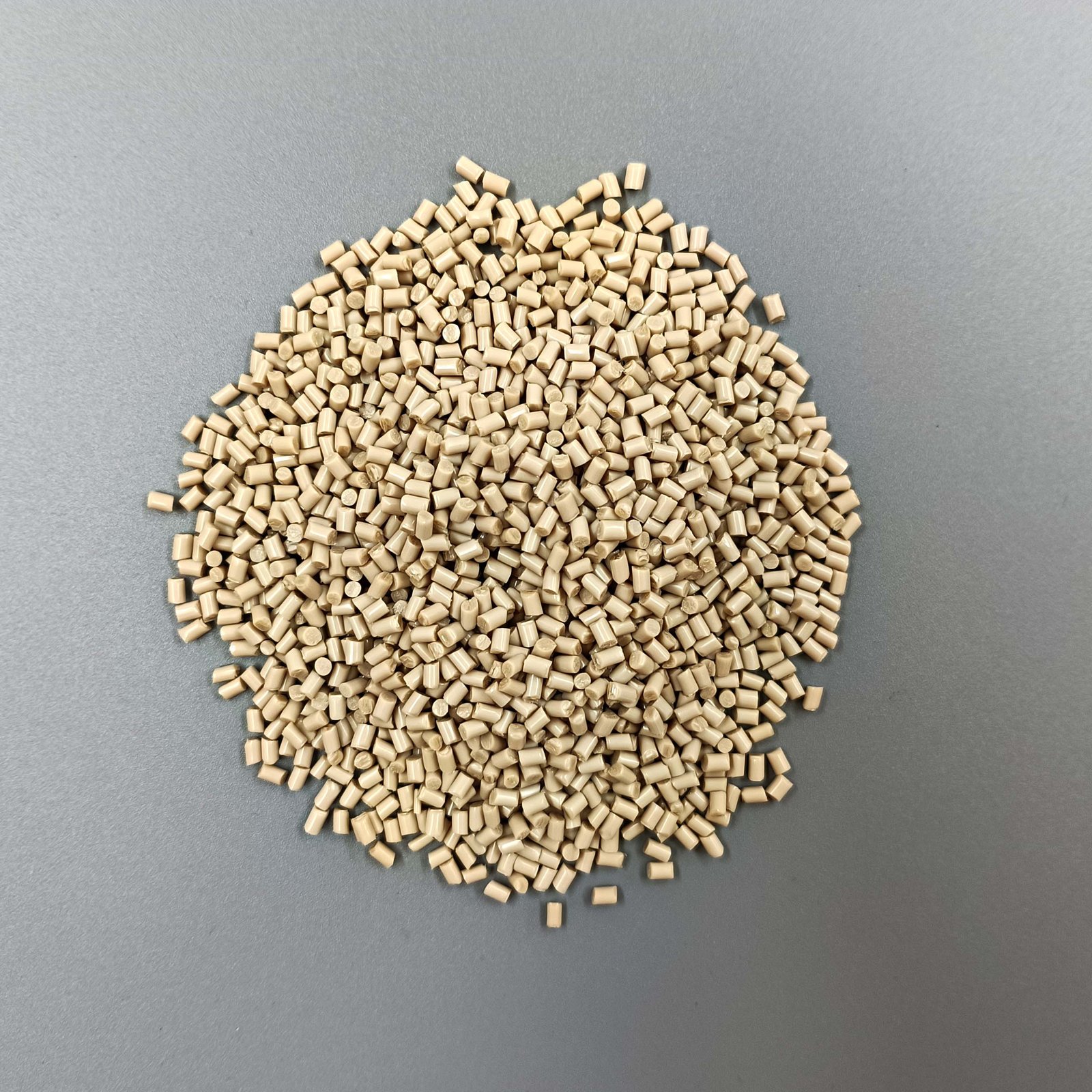

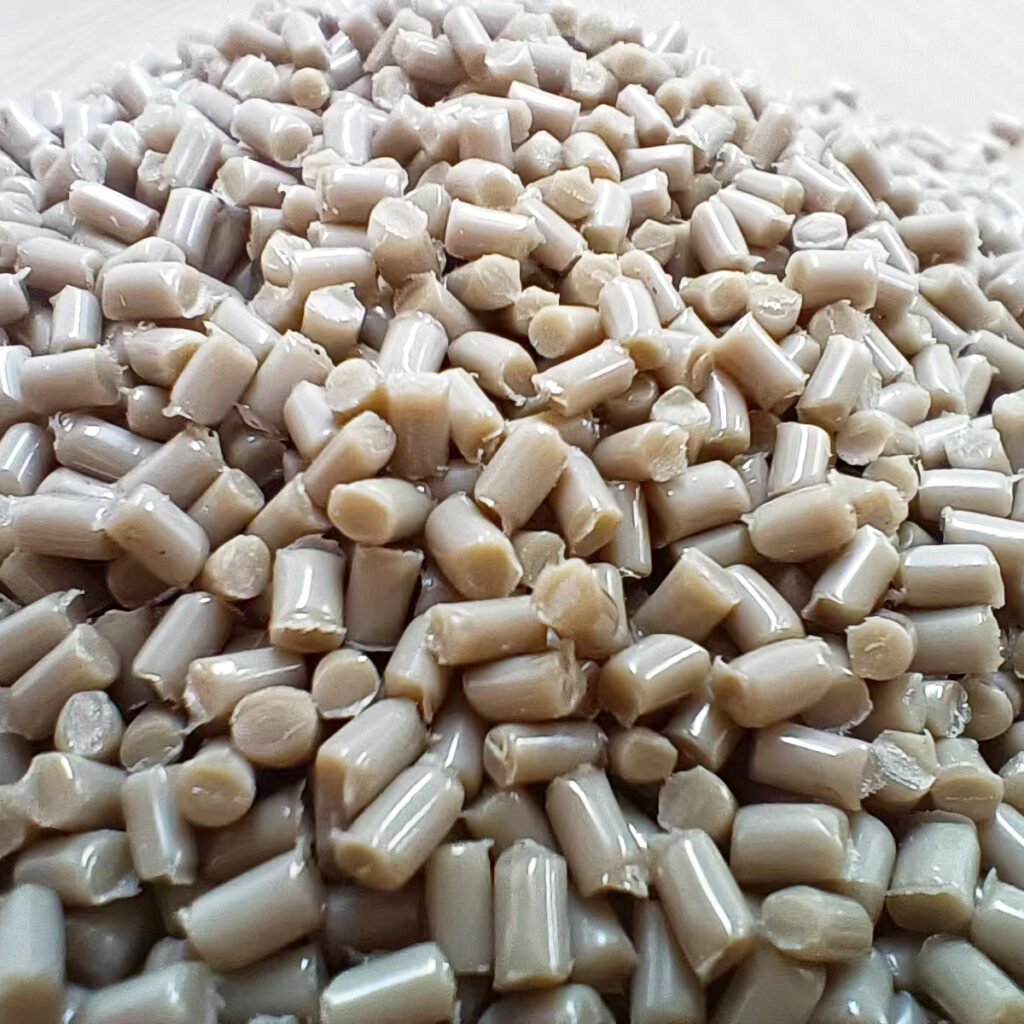

RTP 2200 Series Low Flow PEEK Resin | 2200 LF to 2285 LF

Product Struction

What is PEEK Resin

With the continuous expansion of the application of high-performance engineering plastics in the aerospace, automotive, medical and electronic and electrical industries, polyetheretherketone (PEEK), as the most representative high-end plastic, has gradually become an important choice for metal alternatives due to its outstanding high-temperature resistance, mechanical strength and chemical resistance.

The 2200 series low-flowability PEEK Resin developed by RTP Company, while maintaining the basic properties of PEEK, is reinforced/modified with glass fiber, carbon fiber, PTFE and aramid fiber, etc., endowing the material with a richer combination of properties to meet the demanding requirements of different working conditions.

01 | Product Overview

The RTP 2200 series belongs to low-flowability modified PEEK and is more suitable for injection molding with high-precision and complex molds. This series of products achieves the following performance characteristics through different reinforcing filling schemes:

・High strength and high modulus: The glass fiber and carbon fiber reinforced type significantly enhances structural strength and is suitable for load-bearing parts.

・Stable high-temperature resistance: The heat distortion temperature of some models can reach up to 316℃, meeting the requirements of harsh environments.

・Wear resistance and self-lubrication: PTFE-modified types exhibit a low coefficient of friction, making them suitable for sliding and rotating components.

・The comprehensive performance is adjustable: from toughness to rigidity, from lightweight to wear resistance, covering different application requirements.

02 | Numerical Comparison Table of RTP 2200 Series

| Product Model | Density | Tensile Strength | Elongation | Shrinkage Rate | Tensile Modulus | HDT | Notched Izod Impact Strength | Flexural Modulus | Unnotched Izod Impact Strength | Flexural Strength |

| 2205 LF | 1.52 g/cm³ | 172 MPa | 2.5 % | 0.30 % | 11722 MPa | 316 ℃ | 117 J/m | 11032 MPa | 908 J/m | 255 MPa |

| 2207 LF | 1.61 g/cm³ | 186 MPa | 2.5 % | 0.20 % | 15169 MPa | 316 ℃ | 133 J/m | 13790 MPa | 961 J/m | 290 MPa |

| 2285 LF | 1.41 g/cm³ | 248 MPa | 1.7 % | 0.05 % | 25512 MPa | 316 ℃ | 85 J/m | 24132 MPa | 747 J/m | 365 MPa |

| 2200 LF AR 15 TFE 15 | 1.40 g/cm³ | 86 MPa | 2.5~4.0 % | 0.50~1.20 % | 5171 MPa | 163 ℃ | 43 J/m | 4826 MPa | 400 J/m | 145 MPa |

| 2201 LF | 1.37 g/cm³ | 124 MPa | 5.0 % | 0.60 % | 6206 MPa | 69 J/m | 5516 MPa | 854 J/m | 193 MPa | |

| 2205 LF TFE 15 | 1.64 g/cm³ | 159 MPa | 2.5~4.0 % | 0.20~0.50 % | 12756 MPa | 260 ℃ | 133 J/m | 11032 MPa | 961 J/m | 234 MPa |

| 2203 LF | 1.44 g/cm³ | 152 MPa | 3.5 % | 0.40 % | 8964 MPa | 288 ℃ | 96 J/m | 8274 MPa | 908 J/m | 228 MPa |

| 2200 LF TFE 15 | 1.36 g/cm³ | 76 MPa | 10.0 % | 1.00~1.50 % | 2758 MPa | 171 ℃ | 80 J/m | 3792 MPa | 138 MPa | |

| 2200 LF TFE 5 | 1.32 g/cm³ | 94 MPa | 20.0 % | 1.20 % | 3792 MPa | 160 ℃ | 107 J/m | 3792 MPa | 2136 J/m | 145 MPa |

| 2283 LF | 1.36 g/cm³ | 221 MPa | 1.8 % | 0.10 % | 19996 MPa | 316 ℃ | 85 J/m | 17238 MPa | 747 J/m | 331 MPa |

| 2200 LF | 1.30 | 93 | 10.0 | 1.00~1.60 | 3792 | 53 | 3792 | 2136 | 145 | |

| 2287 LF | 1.45 g/cm³ | 265 MPa | 1.4 % | 0.05 % | 34475 MPa | 316 ℃ | 91 J/m | 30338 MPa | 747 J/m | 379 MPa |

03 | Star Rating Comparison of RTP 2200 Series Characteristics

| Product Model | Reinforcement/Filler Type | Strength | Heat Resistance | Toughness | Wear Resistance |

| 2200 LF | Unreinforced | ⭐⭐ | ⭐⭐ | ⭐⭐⭐⭐ | ⭐⭐ |

| 2201 LF (10% GF) | Glass Fiber | ⭐⭐⭐ | ⭐⭐ | ⭐⭐⭐ | ⭐⭐ |

| 2203 LF (20% GF) | Glass Fiber | ⭐⭐⭐⭐ | ⭐⭐⭐ | ⭐⭐⭐ | ⭐⭐ |

| 2205 LF (30% GF) | Glass Fiber | ⭐⭐⭐⭐ | ⭐⭐⭐⭐ | ⭐⭐ | ⭐⭐ |

| 2207 LF (40% GF) | Glass Fiber | ⭐⭐⭐⭐⭐ | ⭐⭐⭐⭐ | ⭐ | ⭐⭐ |

| 2283 LF (20% CF) | Carbon Fiber | ⭐⭐⭐⭐ | ⭐⭐⭐⭐ | ⭐⭐ | ⭐⭐⭐ |

| 2285 LF (30% CF) | Carbon Fiber | ⭐⭐⭐⭐⭐ | ⭐⭐⭐⭐ | ⭐ | ⭐⭐⭐ |

| 2287 LF (40% CF) | Carbon Fiber | ⭐⭐⭐⭐⭐ | ⭐⭐⭐⭐ | ⭐ | ⭐⭐⭐ |

| 2200 LF TFE 5 | PTFE | ⭐⭐ | ⭐⭐ | ⭐⭐⭐⭐⭐ | ⭐⭐⭐ |

| 2200 LF TFE 15 | PTFE | ⭐⭐ | ⭐ | ⭐⭐⭐⭐⭐ | ⭐⭐⭐⭐ |

| 2205 LF TFE 15 | GF + PTFE | ⭐⭐⭐⭐ | ⭐⭐⭐ | ⭐⭐ | ⭐⭐⭐⭐ |

| 2200 LF AR15 TFE15 | Aramid + PTFE | ⭐⭐⭐ | ⭐ | ⭐⭐⭐⭐ | ⭐⭐⭐⭐ |

04 | Selection Suggestions

Pursue high-strength/rigid structural components

・Recommended: 2205 LF / 2207 LF (30%-40% glass fiber) or 2285 LF / 2287 LF (30%-40% carbon fiber)

・Features: High modulus, suitable for long-term load-bearing parts.

The demand for lightweight and high modulus

・Preferred: Carbon fiber reinforced series (2283/2285/2287 LF)

・Features: High strength and light weight.

Wear-resistant/self-lubricating applications

・Selection: PTFE series (2200 LF TFE 5 / TFE15) or composite (2205 LF TFE15/2200 LF AR15 TFE15)

・Features: Low coefficient of friction and long service life.

Comprehensive performance balance

・Recommended: 2201 LF (10% GF) and 2203 LF (20% GF)

・Features: Balanced strength and toughness, suitable for general structural components.

Maintain the original toughness and chemical resistance

・Selection: 2200 LF (unreinforced substrate)

・Features: Suitable for applications that require high impact resistance and chemical stability.

05 | Summary of Material Highlights and Characteristics

Outstanding heat resistance: The heat distortion temperature of some models can reach 316℃.

Corrosion resistance and chemical stability: Remains stable in acidic, alkaline and solvent environments.

Lightweight: Lighter than metal but maintaining high strength.

Good dimensional stability: Suitable for precision parts.

Wear resistance and self-lubrication: Particularly suitable for long-term friction conditions.

06 | Typical Application Cases

Automobile: Brake system parts, heat-resistant components in the engine compartment.

Aerospace: Structural components, interior connectors, lightweight support components.

Medical: Surgical instruments, sterilized components.

Industrial equipment: gears, sliding bearings, pump and valve parts.

Electronic and electrical: insulating parts, high-temperature connectors, switch components.

07 | Key Points of Processing Technology

Injection molding process: The mold temperature is recommended to be ≥ 180℃, and the melting temperature is 370-400℃.

High-filling model: Requires higher injection pressure to ensure mold filling.

PTFE/ aramid composite model: Relatively improved fluidity, suitable for thin-walled parts.

Drying conditions: It is recommended to dry at 150℃ for 3 to 4 hours to avoid moisture absorption affecting performance.

08 | Industry Trends and Innovations

The application of PEEK resin in replacing metals, lightweight design and resistance to extreme working conditions is growing rapidly.

The RTP 2200 series offers more feasible solutions for aerospace, medical and new energy vehicles through low fluidity and composite enhancement.

In the future, composite filled PEEK will play a greater role in intelligent manufacturing and green energy equipment.

09 | Our Supply Advantages

Rich model coverage: from pure substrates to various reinforcing and filling series.

Small-batch samples + large-batch supply: Flexibly meeting the needs of different customers.

Technical support: Provide selection consultation and process guidance.

International certifications: UL, ISO, ROHS and other certification materials can be provided.

Global logistics support: Fast delivery to ensure project progress.

10 | Frequently Asked Questions (FAQ)

Q1: What are the differences between RTP 2200 and ordinary PEEK resin?

A: The RTP 2200 series is A low-flowability PEEK that has been modified with glass fiber, carbon fiber, PTFE, etc., making its performance more targeted and suitable for complex working conditions.

Q2: Which model is the most suitable for gear applications?

A: It is recommended to choose PTFE modified or GF+PTFE models, which have better wear resistance and self-lubricating properties.

Q3: Can it be used for medical or food contact?

A: Some models can be provided with grades that comply with FDA or ISO medical certifications. Please specify the application scenario when purchasing.

Q4: How to choose between carbon fiber reinforcement and glass fiber reinforcement?

A: The carbon fiber series is lighter and has a higher modulus, while the glass fiber series offers better value for money. The choice depends on weight and budget requirements.

11 | Conclusion

The RTP 2200 series PEEK Resin offers a flexible combination of properties among strength, heat resistance, wear resistance and toughness, making it an ideal choice for high-end engineering fields. Through parameter comparison tables, intuitive star level comparisons and detailed application suggestions, engineers and purchasing personnel can quickly match suitable models, enhancing product performance and market competitiveness.

【Related Recommendations】

October 2025 Virgin Plastic Raw Materials Market Insights | Juyuan Perspective Learn more>

Victrex 450FE20 — PEEK Natural Material for Chemical & Wear Resistance Learn more>

Americhem InLube™ Lubricated PEEK Polymer for Low-Friction Use Learn more>