PRODUCTS

High Quality PP CB5108H plastic raw materials

Product Struction

Polypropylene (PP), a thermoplastic polymer widely used across multiple industry sectors due to its unique properties, has seen further development and optimization in recent years with the advancement of material science. Specifically, the PP CB5108H model of polypropylene, with its excellent physical and chemical characteristics, offers users a wider range of possibilities and applications. This article aims to delve into the characteristics of PP CB5108H and its broad application fields, demonstrating how this material plays an indispensable role in modern industry and everyday life.

Polypropylene is a long-chain polymer formed by the polymerization of propylene monomers. It is a lightweight, high-strength material with good chemical resistance, fatigue resistance, and impact resistance. The density of PP is low, at only 0.90-0.91g/cm³, making it very popular in applications requiring lightweight materials. In addition, PP also possesses excellent electrical insulation properties and relatively good transparency, making it an ideal choice for electronic and electrical applications.

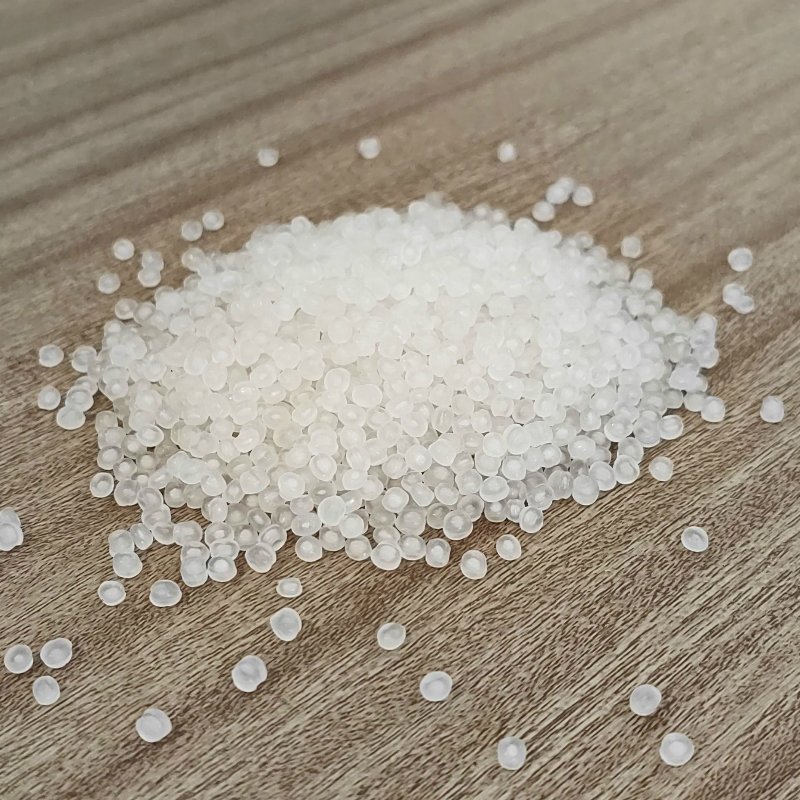

PP CB5108H, as a special model of PP, is a granular material made through block copolymer technology, primarily formed by injection molding. It features molding-grade and heat-resistant characteristics, as well as advantages such as high gloss, scratch resistance, high impact, and high rigidity. These features make PP CB5108H an ideal material for automotive parts, electronic and electrical applications, and household appliance casings.

PP CB5108H demonstrates outstanding physical properties, including a tensile strength of 330kg/cm², an elongation at break of 200%, and a flexural modulus of 17000kg/cm². Its cantilever beam notch impact test shows results of 10kg-cm/cm at 25℃ and 3kg-cm/cm at -20℃, indicating good impact resistance at different temperatures. Furthermore, the heat deflection temperature of PP CB5108H is 135℃, its melting temperature is 167℃, and its Vicat softening temperature is 153℃, further proving its stability and long-term heat resistance at high temperatures.

In terms of material performance, PP CB5108H has a density of 0.91g/cm³, a melt flow index of 10g/10min, and a shrinkage rate of 1.4~1.8%, indicating good flow and molding properties during the injection molding process.

PP CB5108H not only inherits the basic advantages of polypropylene, such as being lightweight, high-strength, good chemical resistance, and electrical insulation, but also showcases its wide application potential in modern industry and life through special preparation processes and optimized physical properties.