PRODUCTS

RADEL® R-7159 Series | PPSU Aerospace-Grade Material Guide

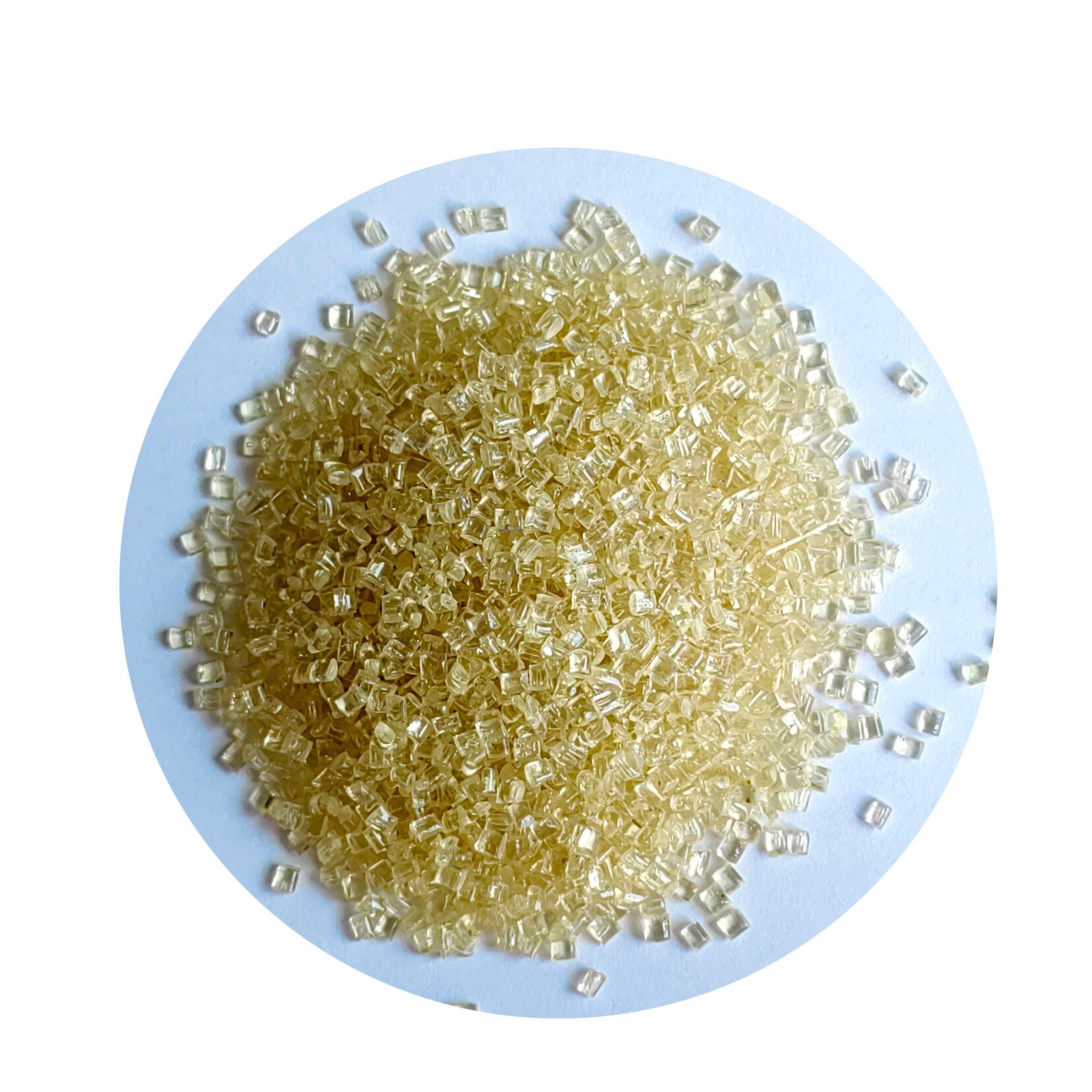

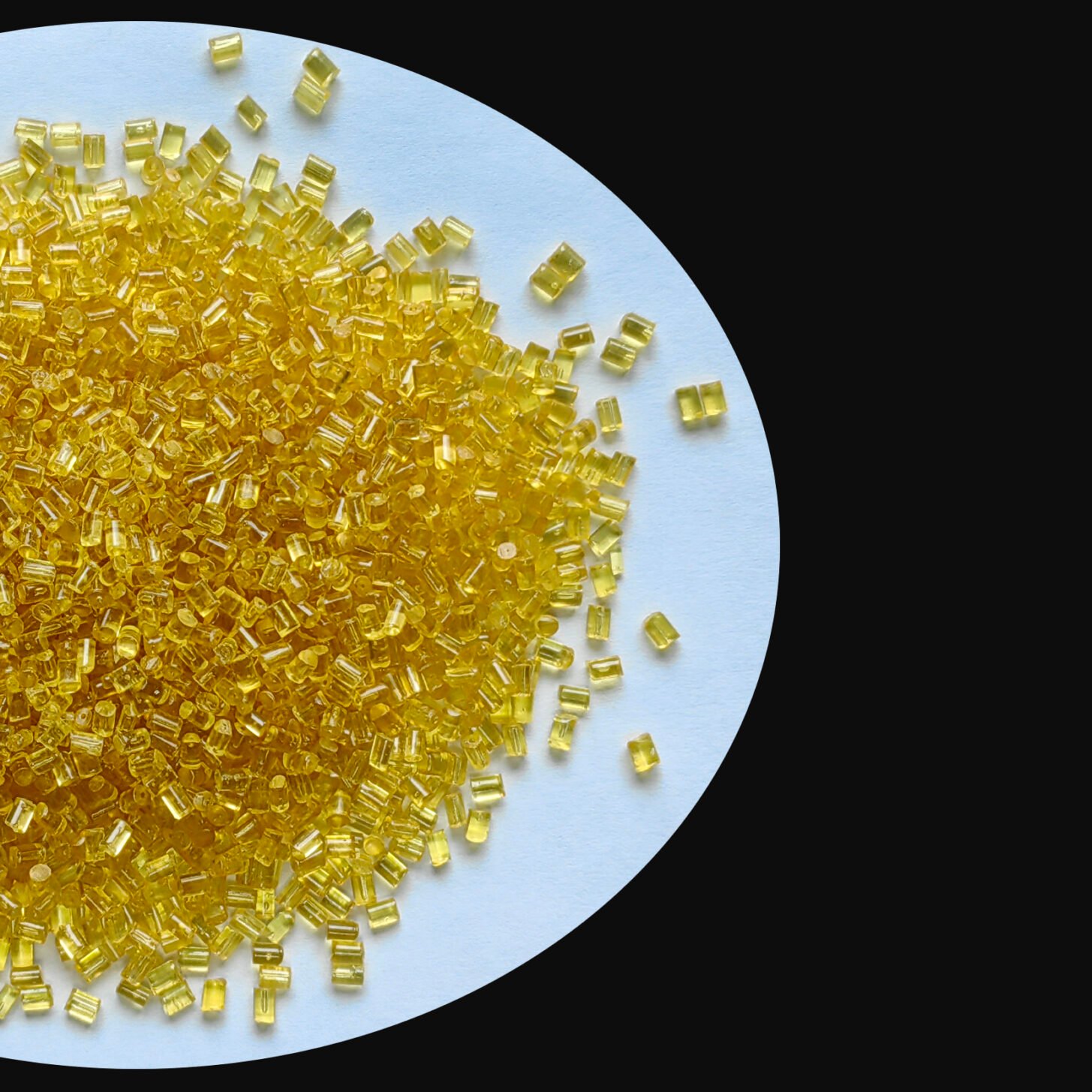

Product Struction

What is RADEL® R-7159

In the aerospace and high-end manufacturing sectors, material safety, reliability, and process compatibility are crucial. Solvay's RADEL® PPSU R-7159 series, a representative flame-retardant polyphenylsulfone (PPSU-FR), is widely used in aircraft interiors and structural components due to its excellent heat resistance, flame retardancy, and chemical stability.

However, buyers often face the question of how to choose among the multiple models within the same series. This article will comprehensively review the common advantages and differences between the radel r-7159 series models, helping you quickly find the right material.

01 | Common Advantages of the RADEL® R-7159 Series

The RADEL® R-7159 series was designed from the outset with the needs of the aerospace industry in mind, offering the following notable features:

・Flame retardancy and low smoke toxicity: Meets aviation safety standards.

・Excellent thermal properties: A heat deflection temperature (HDT) of up to 200°C allows for adaptability to extreme environments.

・Excellent mechanical properties: High toughness and strong impact resistance ensure long-term service safety.

・Excellent chemical stability: Resistant to cleaning agents and a variety of chemicals.

・Processing Ease: Suitable for injection molding, with high fluidity, it facilitates the molding of complex parts.

・Wide Applications: Key areas such as aircraft seats, interior panels, ventilation systems, and decorative components.

02 | Model Comparison and Application Highlights

| Grade | Color | Key Highlights | Typical Applications | Key Performance Parameters |

| R-7159 GY 714 | Gray | General-purpose, balanced performance and processability | Aircraft interior parts, panels | Elongation 10%, Flexural Strength 103 MPa, MFR 19 g/10min |

| R-7159 BU 7923 | Blue | Excellent decorative effect, easy color differentiation | Cabin components, visible parts | Same performance as gray grade |

| R-7159 WH 7363 | White | High surface gloss, suitable for coating and surface treatment | Decorative parts, visible components | Impact Strength 210 J/m, Flexural Strength 103 MPa |

| R-7159 BK 937 | Black | Superior mechanical properties, wider toughness range | Structural parts, functional components | Tensile Strength 74.5 MPa, Elongation 30–50%, MFR 22 g/10min |

| R-7159 WH 70913 | White | Stable performance, similar to gray/blue grades | Lightweight interior design | Elongation 10%, MFR 19 g/10min |

| R-7159 NT 50 | Natural | High strength, suitable for post-dyeing or coating | Multifunctional components | Tensile Strength 74.5 MPa, Elongation 30–50%, MFR 22 g/10min |

03 | Purchasing Recommendations

・For aesthetics and decorative features, we recommend Blue BU 7923 or White WH 7363/70913.

・For structural strength and toughness, we recommend Black BK 937 or Natural NT 50.

・For a balance between performance and cost, we recommend Gray GY 714, which offers a stable fit for conventional aircraft interiors.

The above classification allows buyers to identify the appropriate model based on their color needs, mechanical performance requirements, and application scenarios.

04 | Frequently Asked Questions (FAQs)

Q1: Are the various RADEL® R-7159 grades interchangeable?

A1: From a performance perspective, most grades in the R-7159 series have similar thermal, flame retardancy, and basic mechanical properties, making them interchangeable in most applications. However, if color, appearance, or specific mechanical properties are required (such as the high elongation of black BK 937 and natural NT 50, or the decorative properties of blue/white), we recommend selecting based on the specific application.

Q2: Is the RADEL® R-7159 series aerospace-certified?

A2: Yes, this series was developed specifically for the aerospace industry and meets FAR 25.853 aviation flame retardancy standards. It is widely used in aircraft interiors, seats, ventilation systems, and decorative parts.

Q3: Are these grades suitable for thin-walled injection molding?

A3: RADEL® R-7159 has high flowability, making it ideal for injection molding complex, thin-walled parts. These are commonly found in lightweight cabin interior components.

Q4: What are the advantages of black BK 937 and natural NT 50?

A4: Both grades offer enhanced mechanical properties, with elongations of 30% to 50%, making them ideal for structural parts subject to mechanical loads or parts requiring additional durability.

Q5: As a buyer, how can I quickly select the right model?

A5: We recommend considering three key factors:

・Color/Appearance → Blue/white are suitable for visible parts, while black/gray/natural colors are suitable for structural or concealed parts.

・Mechanical Properties → For high toughness requirements, choose BK 937 or NT 50; for general applications, consider GY 714, BU 7923, or WH 70913.

・Processing and Secondary Treatments → If painting or dyeing is required, choose white or natural colors.

05 | Conclusion and Our Advantages

The RADEL® R-7159 series not only meets the extremely high flame retardancy and safety requirements of the aerospace industry, but also offers a variety of models to meet the differentiated needs of various application scenarios.

As a professional plastic raw material trader, our company has long been dealing in the full Solvay RADEL® PPSU R-7159 product line, offering:

・Full range of models.

・In-stock and fast delivery to meet urgent project needs.

・Technical support and selection consultation help customers reduce trial-and-error costs.

👉 If you're looking for a stable supply of RADEL® R-7159 Series PPSU, please contact us for more information and a quote.

【Related Recommendations】

From Plastic Pellets to Films: A Complete Guide from Material Selection to Applications Learn more>

Solvay Radel® R-5100 PPSU Flame-Retardant Guide | Juyuan Learn more>

Radel® R-5500 Series PPSU Materials Overview | Juyuan Supply Learn more>