PRODUCTS

Radel D3000 Crack Resistance & Thin-Wall PPSU Plastic Material

Product Struction

What is PPSU Plastic Material

In the realm of high-performance engineering plastics, Duradex® D3000 PPSU Plastic Material, with its exceptional thermal stability, hydrolysis resistance, and superior electrical properties, is an ideal material for the healthcare, food safety, and thin-walled product industries. As Solvay's flagship PPSU, D-3000 represents not only reliability and quality, but also industry innovation and breakthroughs in applications.

01 | Material highlights and characteristics

Duradex® D3000 incorporates characteristics such as stress crack resistance, corrosion resistance, excellent electrical performance and high flexural temperature in its material design, which enables it to maintain stable performance under high temperatures, strong stresses and harsh environments.

Its key highlights include:

・Thermal stability grade and hydrolysis resistance grade ensure that physical and chemical stability remains in long-term steam and hot water environments.

・Flame retardant performance (UL94 V-0), meeting high safety standards;

・Steam sterilization is compatible and can be repeatedly subjected to high-pressure sterilization without damaging the structure.

・Mechanical toughness and dimensional stability are particularly prominent in thin-walled applications.

These characteristics make Duradex® D3000 stand out among numerous PPSU plastic materials, becoming a comprehensive material that takes into account strength, toughness and safety.

02 | Multi-field applications

Thanks to its unique performance combination, the Duradex® D3000 is widely used in:

・Medical and health care field: baby bottles, medical device components, and care products that require frequent high-temperature disinfection;

・Food contact parts: Comply with food contact safety requirements and are suitable for products in repeatedly heated environments.

・Thin-walled applications: Achieving a balance between strength and fluidity to meet the requirements of lightweight and complex structure forming.

Whether it is the baby bottles used by infants and toddlers in daily life or the precision medical equipment, Duradex® D3000 PPSU plastic material can provide long-term reliable guarantee.

03 | Process technology and processing advantages

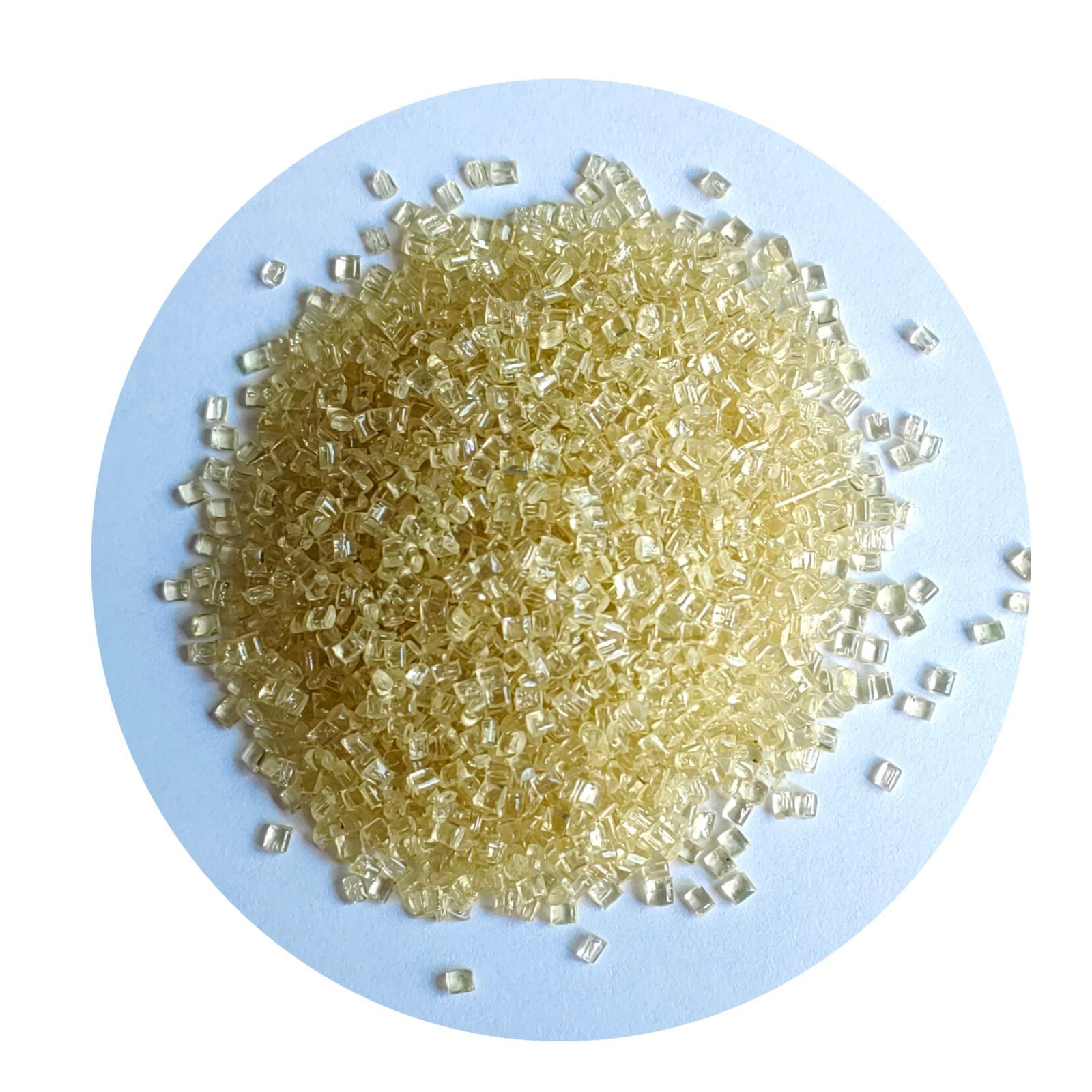

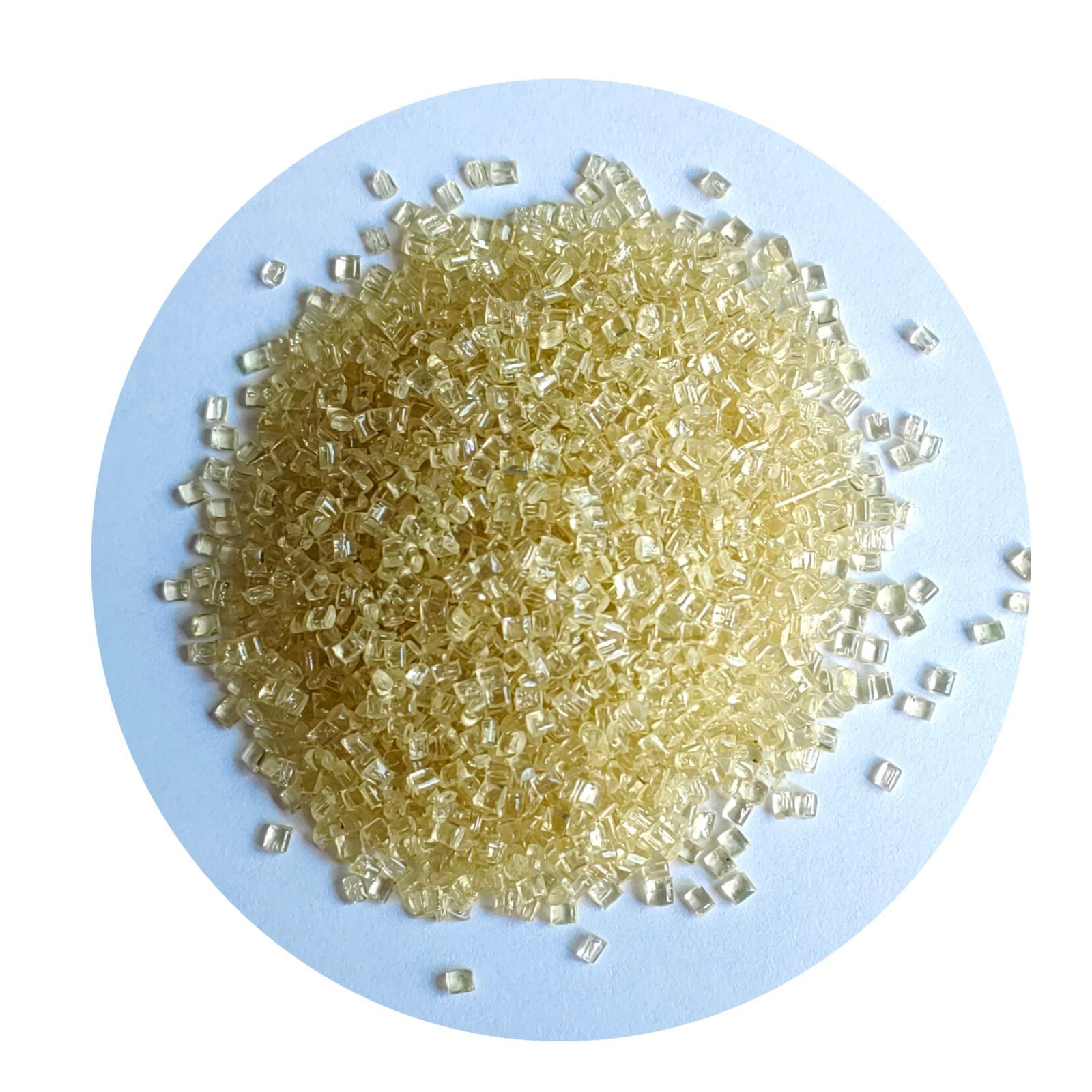

Duradex® D-3000 is provided in granular form and is suitable for injection molding processes, featuring excellent fluidity and processing stability. It is particularly friendly to the forming of thin-walled parts, not only reducing the processing difficulty but also improving production efficiency.

Meanwhile, the material has the following advantages in terms of processing degree:

・Low dimensional shrinkage rate ensures the consistency and accuracy of the products.

・The melt index is moderate, which not only ensures the processing speed but also takes into account the structural performance.

・High stress crack resistance reduces the risk of failure caused by internal stress after molding.

04 | Innovation and industry competitive advantage

Compared with traditional polycarbonate (PC) or PSU, the innovative advantage of Duradex® D3000 PPSU Plastic Material lies in:

・It performs better in terms of steam sterilization resistance and can withstand hundreds of high-pressure sterilization cycles.

・It has a high balance between mechanical and thermal properties and remains stable above 200℃.

・Widely certified, it complies with multiple international standards such as UL and IEC, and is suitable for the global market demand.

This gives it greater recognition and competitive advantages in the healthcare and food safety markets.

05 | Duradex® D3000 PPSU Plastic Material Data Sheet

| Flammability | Condition | Standard | Value | Unit | |||

| Flame | Rating All Color 0.75mm | UL94 | V-0 | ||||

| Flame | Rating All Color 1.5mm | UL94 | V-0 | ||||

| Flame | Rating All Color 3.0mm | UL94 | V-0 | ||||

| Mechanical behavior | Condition | Standard | Value | Unit | |||

| Elongation | Yield | ASTM D638 | 7.2 | % | |||

| Elongation | Break | ASTM D638 | 60~120 | % | |||

| Flexural | Strength | ASTM D790 | 100 | MPa | |||

| Flexural | Modulus | ASTM D790 | 2.3 | GPa | |||

| Izod | Notch Impact | ASTM D256 | 640 | J/m | |||

| Tensile | Modulus | ASTM D638 | 2.3 | GPa | |||

| Tensile | Strength | ASTM D638 | 70 | MPa | |||

| Physical property | Condition | Standard | Value | Unit | |||

| Density | ASTM D792 | 1.29 | g/cm³ | ||||

| Melt | Index 365°C 5kg | ASTM D1238 | 30 | g/10min | |||

| Shrinkage | ASTM D955 | 0.7 | % | ||||

| Water | Absorption 24hr | ASTM D570 | 0.37 | % | |||

| Thermal | Condition | Standard | Value | Unit | |||

| CLE | ASTM D696 | 5.6E-5 | cm/cm/°C | ||||

| Glass | Transition Temperature | INTERNAL METHOD | 220 | °C | |||

| HDT | 1.8MPa | ASTM D648 | 204 | °C | |||

| UL | Condition | Standard | Value | Unit | |||

| Arc | Resistance | ASTM D495 | 5 | PLC | |||

| Ball | Pressure | IEC 60695-10-2 | 125 | °C | |||

| Comparative | Tracking Index | IEC 60112 | 5 | PLC | |||

| Dielectric | Strength | ASTM D149 | 36 | KV/mm | |||

| GWFI | 1.5mm | IEC 60695-2-12 | 960 | °C | |||

| GWFI | 3.0mm | IEC 60695-2-12 | 960 | °C | |||

| GWIT | 1.5mm | IEC 60695-2-13 | 875 | °C | |||

| GWIT | 3.0mm | IEC 60695-2-13 | 850 | °C | |||

| HAI | ALL 0.75mm | UL 746A | 0 | PLC | |||

| HAI | ALL 1.5mm | UL 746A | 0 | PLC | |||

| HAI | ALL 3.0mm | UL 746A | 0 | PLC | |||

| HVTR | UL 746A | 0 | PLC | ||||

| HWI | ALL 0.75mm | UL 746A | 0 | PLC | |||

| HWI | ALL 1.5mm | UL 746A | 0 | PLC | |||

| HWI | ALL 3.0mm | UL 746A | 0 | PLC | |||

| RTI | Elec ALL 0.75mm | UL 746B | 180 | °C | |||

| RTI | Elec ALL 1.5mm | UL 746B | 180 | °C | |||

| RTI | Elec ALL 3.0mm | UL 746B | 180 | °C | |||

| RTI | Imp ALL 0.75mm | UL 746B | 180 | °C | |||

| RTI | Imp ALL 1.5mm | UL 746B | 180 | °C | |||

| RTI | Imp ALL 3.0mm | UL 746B | 180 | °C | |||

| RTI | Str ALL 0.75mm | UL 746B | 180 | °C | |||

| RTI | Str ALL 1.5mm | UL 746B | 180 | °C | |||

| RTI | Str ALL 3.0mm | UL 746B | 180 | °C | |||

| UL | FlameRating ALL 0.75mm | UL94 | V-0 | ||||

| UL | FlameRating ALL 1.5mm | UL94 | V-0 | ||||

| UL | FlameRating ALL 3.0mm | UL94 | V-0 | ||||

| Volume | Resistivity | ASTM D257 | 1E+19 | Ω.cm | |||

06 | Customer Feedback

Many customers have reported the following after using Duradex® D3000:

・Extended product life: This is particularly true for baby bottles and medical consumables, which maintain transparency and mechanical strength even after repeated sterilization.

・Improved processing efficiency: Stable injection molding process, reduced scrap rate;

・Enhanced brand trust: Downstream customers have a greater recognition of the safety and durability of PPSU products.

07 | FAQ Frequently Asked Questions

Q1: What makes the Duradex® D3000 different from other PPsus?

A1: It belongs to the special grade for thermal stability and hydrolysis resistance, and is particularly suitable for repeated high-pressure steam environments.

Q2: For which processes is it suitable?

A2: It is mainly used for injection molding, especially suitable for thin-walled parts and products with high requirements for dimensional accuracy.

Q3: Can it be directly used for food contact or medical purposes?

A3: Yes, the material complies with food contact and medical certification standards and can be used with confidence.

08 | Recommendations for Similar Materials

| Manufacturer | Product Name | Product Model | Density | Melt Flow Index |

| Solvay | PPSU | R-5800BK937 | 1.29 g/cm³ | 24 g/10min |

| Solvay | PPSU | R-5100 WH837 | 1.3 g/cm³ | 17 g/10min |

| Solvay | PPSU | RG-5030 NT 20 | 1.55 g/cm³ | 14 g/10min |

| Solvay | PPSU | R-5100 BU940 | 1.3 g/cm³ | 17 g/10min |

| Solvay | PPSU | R-5100 GY710 | 1.3 g/cm³ | 17 g/10min |

| Solvay | PPSU | R-5800 TR BU301 | 1.29 g/cm³ | 24 g/10min |

| Solvay | PPSU | R-5800 TR BK561 | 1.29 g/cm³ | 24 g/10min |

| Solvay | PPSU | R-5800 TR FS531 | 1.29 g/cm³ | 24 g/10min |

09 | Juyuan supplier advantages

Multi-channel procurement capability: Relying on the global procurement network, quickly match suitable PPSU Material resources for customers.

Flexible supply and inventory support: We can provide small-batch trial orders and bulk supply based on customer needs to reduce inventory pressure.

Cross-industry service experience: 24 years of experience in plastic raw material trading, familiar with application requirements in industries such as medical care, food, and automobiles.

Professional logistics and compliance support: We offer export customs declaration, transportation solutions and international compliance documents to help clients reduce trade risks.

Rapid response and customized services: Customers can obtain material selection suggestions, alternative solutions and timely after-sales support.

Summary

Duradex® D3000 PPSU Plastic Material is more than just an engineering plastic; it's a solution designed for demanding industry applications. From medical to food, from heat resistance to flame retardancy, its unique properties and excellent processing performance have made it a recognized material of choice in the global market.

【Related Recommendations】

XENOY™ 6370: High-Toughness, Ductile PC+PBT Engineering Plastic Learn more>

Radel® R-5000 PPSU Material for Medical, Food & High-Temperature Applications Learn more>

XENOY™ 5220U with PC+PBT Low-Temperature Toughness Learn more>