PRODUCTS

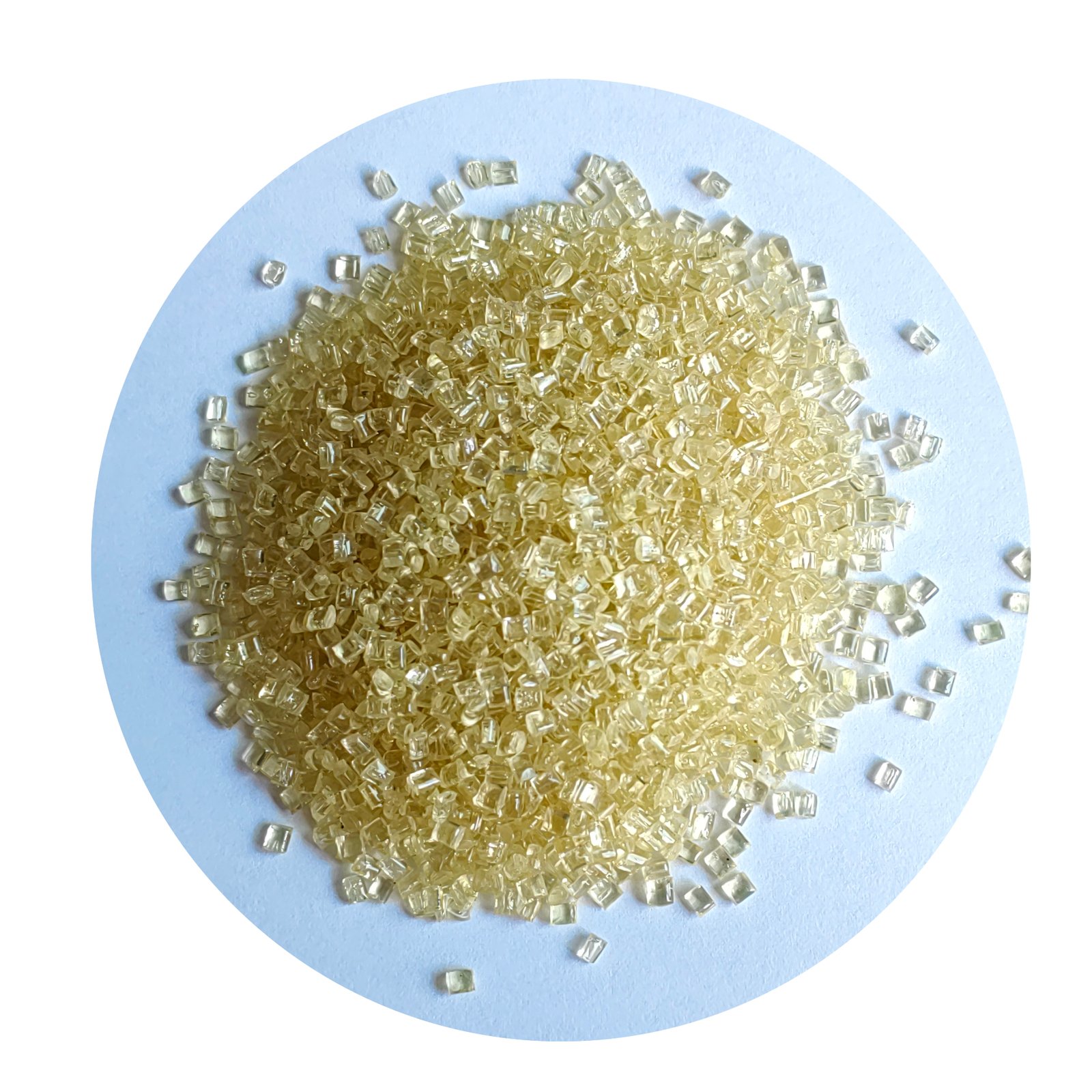

PESU 3010 MR UN Overview | PES Plastic for Rail Applications

Product Struction

What is PES Plastic

In the field of high-reliability engineering manufacturing, the balance between performance and process has always been the core challenge in material selection. As a high-viscosity polyethersulfone material specially designed for extreme conditions, BASF PESU 3010 MR UN is redefining "non-reinforced high-performance plastics". This flame-retardant pes plastic launched by BASF not only features excellent thermal stability and mechanical strength, but also is compatible with multiple processing techniques, bringing more flexible material solutions to industries such as medical care, rail transit, and electronic and electrical.

01 | Redefine the performance boundaries of "non-enhanced"

The structural design of PESU 3010 MR UN eliminates the traditional glass fiber reinforced path, yet still possesses excellent mechanical toughness, dimensional stability and chemical resistance. The main features include:

・High viscosity + non-reinforcing: It still maintains excellent impact strength (8 kJ/m²) without fillers, and the internal structure of the material is highly uniform.

・Outstanding thermal stability: The heat distortion temperature can reach up to 207°C, and the glass transition temperature is 228°C, capable of withstanding high-temperature and repeated stress environments.

・Strong resistance to chemical corrosion: Suitable for industrial scenarios involving contact with cleaning agents, solvents, alcohols and strong alkalis, etc.

・Flame retardant grade V-0: It meets the flame retardant requirements without adding halogen and complies with RoHS and REACH regulatory standards.

・Multi-process compatibility: Supports injection molding, extrusion, and blow molding processes, meeting a wide range of manufacturing requirements from precision structures to hollow shells.

This series of attributes enables it to form a unique competitiveness in the field of non-reinforcing materials and is a representative of the new generation of high-end pes materials.

02 | Frontiers of Innovative Applications: The Industry Adaptation Path of PESU 3010 MR UN

✅ Medical Industry

The application scenarios of PESU 3010 MR UN in medical devices are constantly expanding:

・It can withstand high-pressure steam sterilization (134°C, repeated cycles).

・The material itself is BPA-free and meets medical-grade biosafety standards.

・The transparency of the formed part is moderate, which is convenient for observing the operating status of the liquid channel/component.

✅ Electrical and Electronic Field

As a pes plastic with stable electrical performance, it is applicable to:

・High-frequency component structural shells, insulating terminals, sensor housings and other high electric field environments;

・It has insulation advantages such as stable dielectric constant (3.8 to 3.9) and high volume resistance (1E+15 Ω·cm).

・With a low dissipation factor (0.014/1 MHZ), it can be used in precision signal transmission systems.

✅ Industrial and Fluid Control Systems

This material has extremely strong chemical resistance and fatigue resistance, and is suitable for:

・Components such as ultrafiltration membrane housings, chemical pump bodies, and liquid storage boxes that come into contact with corrosive liquids;

・It can still maintain structural integrity under continuous high-temperature and high-pressure environments.

✅ transportation and energy equipment

In rail transit, aviation and new energy equipment, PESU 3010 MR UN provides:

・Lightweight material characteristics + flame retardant safety;

・It is suitable for replacing some metal structural components to achieve weight reduction and modular integration.

・Its performance in resisting long-term high heat and vibration is superior to that of traditional plastic materials.

03 | In-Depth Performance Analysis: The Multidimensional Capabilities of PES Plastic

| Mechanical behavior | Condition | Standard | Value | Unit | |||

| Elongation | Yield 50mm/min | ISO 527 | 6.9 | % | |||

| Izod Notch Impact | 23°C | ISO 180 | 8 | kJ/m² | |||

| Izod Notch Impact | -30°C | ISO 180 | 8 | kJ/m² | |||

| Tensile Strength | Yield 50mm/min | ISO 527 | 85 | MPa | |||

| Tensile Modulus | ISO 527 | 2650 | MPa | ||||

| Charpy Un-notch Impact | 23°C | ISO 179 | NB | kJ/m² | |||

| Charpy Un-notch Impact | -30°C | ISO 179 | NB | kJ/m² | |||

| Charpy Notch Impact | 23°C | ISO 179 | 8 | kJ/m² | |||

| Charpy Notch Impact | -30°C | ISO 179 | 8 | kJ/m² | |||

| Thermal | Condition | Standard | Value | Unit | |||

| Use temperature | 20000hr | IEC 60216 | 180 | °C | |||

| Use temperature | Short Time | 220 | °C | ||||

| HDT | 1.8MPa | ISO 75 | 207 | °C | |||

| Melting Temperature | 350~390 | °C | |||||

| Glass Transition Temperature | 10°C/min | ISO 11357 | 228 | °C | |||

| CLE | Flow 23~80°C | ISO 11359 | 5.2E-5 | cm/cm/°C | |||

| CLE | Flow 180°C | DIN 53752 | 5.9E-5 | cm/cm/°C | |||

| Physical property | Condition | Standard | Value | Unit | |||

| Water Absorption | 23°C | ISO 62 | 2.2 | % | |||

| Water Absorption | 23°C 50RH Balance | ISO 62 | 0.80 | % | |||

| Shrinkage | Flow | ISO 294 | 0.85 | % | |||

| Shrinkage | xFlow | ISO 294 | 0.9 | % | |||

| Density | ISO 1183 | 1.37 | g/cm³ | ||||

| Melt Index | 360°C 10kg | ISO 1133 | 35 | cm³/10min | |||

| Relative Viscosity | ISO 307 | 66 | cm³/g | ||||

| Electrical properties | Condition | Standard | Value | Unit | |||

| CTI | Solution A | IEC 60112 | 100 | V | |||

| Dielectric Constant | 1MHz | IEC 62631-2-1 | 3.8 | ||||

| Dielectric Constant | 100Hz | IEC 62631-2-1 | 3.9 | ||||

| Volume Resistivity | IEC 62631 | 1E+15 | Ω.cm | ||||

| Dielectric Strength | K20/K20 | IEC 60243 | 34 | KV/mm | |||

| Dissipation Factor | 1MHz | IEC 62631-2-1 | 0.014 | ||||

| Dissipation Factor | 100Hz | IEC 62631-2-1 | 0.0017 | ||||

| Hardness | Condition | Standard | Value | Unit | |||

| Ball Indentation Hardness | H358/30 | ISO 2039 | 154 | MPa | |||

| Flammability | Condition | Standard | Value | Unit | |||

| Flame Rating | 1.6mm | UL94 | V-0 | ||||

| Flame Rating | 3mm | UL94 | V-0 | ||||

These figures reveal that PES plastic achieves a well-balanced triad of mechanical, thermal, and electrical properties—giving industrial design engineers the confidence to use it boldly, effectively, and reliably across various high-demand applications.

04 | Convergence of Hot Trends: Why High-viscosity PES Plastic Attracts More Attention?

In recent years, with the continuous increase in demand for sustainable manufacturing, lightweighting, environmental safety, etc., the market for non-reinforced high-performance plastics has been expanding rapidly. PESU 3010 MR UN precisely cuts into the following technological trends:

・Green manufacturing drives the demand for fiberglass-free/halogen-free formula materials.

・The emphasis on lightweight structural components and high strength promotes the application of high-viscosity substrate molding.

・The demand for high-temperature, high-pressure and sterilization-resistant materials in the medical and energy industries has increased.

From this perspective, PESU 3010 MR UN is not only a product of material upgrading, but also a demonstration of the path of "high-performance plastics without reinforcement".

05 | Comparative Insight: Why Choose PESU 3010 MR UN Over Other PESU Grades?

The following table provides a concise comparison between PESU 3010 MR UN and other BASF PESU grades, highlighting their key differences:

| Grade | Viscosity | Processing Methods | Tensile Strength (MPa) | Application Focus |

| PESU 2010 NAT | Medium | Injection Molding | 85 | General-purpose, transparent molding |

| PESU 2010 MR SW | Medium-High | Injection Molding | 85 | Unreinforced, ideal for medical/industrial use |

| Dimension E0510 G9 | Ultra-rigid | Injection, Extrusion | 176 | Carbon-filled, thermally & electrically conductive |

| PESU 3010 MR UN | High | Injection, Extrusion, Blow Molding | 85 | Multi-purpose grade with high toughness and chemical resistance |

Compared to traditional medium-viscosity PESU grades, PESU 3010 MR UN offers greater processing flexibility—especially well-suited for thick-walled and hollow structural parts.

06 | How to determine whether PESU 3010 MR UN is suitable for your product?

・Temperature requirements: If the product operating temperature is higher than 200°C and the material is required to be thermally stable for a long time, PESU 3010 MR UN is a suitable choice.

・Non-reinforced high toughness requirements: This material is suitable for scenarios where fillers such as glass fiber need to be avoided to affect dimensional stability and uniformity.

・Flame retardant and environmental protection requirements: It is required to achieve halogen-free flame retardant V-0 level and comply with RoHS and REACH regulations.

・Processing technology matching: Suitable for injection molding, extrusion and blow molding, and meet the production of complex parts.

・Chemical resistance: The product needs to be in contact with chemical media such as detergents, alcohols or strong alkalis.

If you have a match with the above requirements, you can give priority to PESU 3010 MR UN.

07 | Differentiated Value: When choosing materials, it is even more important to select reliable technical partners

No matter how good the performance of the material is, if it cannot be correctly selected, delivered quickly and responded to promptly, it is difficult to be transformed into product competitiveness. As a service provider with over 24 years of experience in the plastic raw material trade field, we bring not only PES materials themselves, but also the following added values that can be transformed into project advantages:

・Model horizontal comparison + scenario-oriented selection suggestions, not limited to brand recommendations;

・Rapid response to samples, no delay in project connection, and acceleration of product verification.

・One-stop service system, full-process tracking from materials to delivery dates;

・Technical documentation and processing suggestions support save development resources.

08 | Extended Recommended Models

If you show interest in PESU 3010 MR UN, the following models are also worth paying attention to:

| Manufacturer | Material | Grade | Density | MFR (360°C/10kg) | Tensile Modulus | Tensile Strength | Elongation at Break |

| BASF | PESU | 2010 UN Q26 | 1.37 g/cm³ | 70 cm³/10min | 2650 MPa | 85 MPa | 6.9% |

| BASF | PESU | 2010 MR SW HM | 1.37 g/cm³ | 70 cm³/10min | 2650 MPa | 85 MPa | 6.9% |

| BASF | PESU | 2010 C6 | 1.47 g/cm³ | 15 cm³/10min | 22000 MPa | 185 MPa | 1.5% |

| BASF | PESU | 6020 P | — | — | 2650 MPa | 85 MPa | 6.9% |

| BASF | PESU | 2020 P | — | — | 2650 MPa | 85 MPa | 6.9% |

Conclusion

PESU 3010 MR UN is not merely a PES plastic model with good-looking data; it represents a certain direction of material design trends: lightweight, strong and tough, stable and environmentally friendly. If you are looking for a reliable, flexible and high-performance pes plastic solution, please feel free to contact us for more model information and application suggestions. We will provide continuous support for your product design with professional material experience and services.

FAQ

Q1: What industries and applications are suitable for PESU 3010 MR UN?

A: It is widely used in medical devices (supporting high-pressure steam sterilization), electronic and electrical insulation components, high-end rail transit and new energy equipment structural parts, chemical fluid control devices, etc.

Q2: Why is this material called "non-reinforced high-performance plastic"?

A: Although it is not reinforced with fillers such as glass fiber or carbon fiber, it still exhibits excellent mechanical toughness and dimensional stability due to its high viscosity molecular structure.

Q3: What is the flame retardant performance of PESU 3010 MR UN?

A: It meets the V-0 halogen-free flame retardant standard, complies with strict environmental regulations, and is suitable for key applications that require flame retardant safety.

Q4: What processing technologies does this material support?

A: Injection molding, extrusion and blow molding are all possible, which is conducive to the manufacture of precision structural parts and hollow complex parts.

Q5: How can I obtain samples and technical support for PESU 3010 MR UN?

A: Welcome to contact us. We provide fast sample response and detailed technical documentation support to help you quickly complete product development and verification.

【Related Recommendations】

PES and PESU Explained: Choosing the Right Polysulfone for Your Application Learn more>

PESU KR 4113: PES Resin with CF+Graphite+PTFE for Wear-Resistant Applications Learn more>

PESU 2010 HC: Flame-Retardant PES Material for Medical and Electronic Applications Learn more>