PRODUCTS

ExxonMobil POE 5061 Overview | POE Resin for Flexible Films

Product Struction

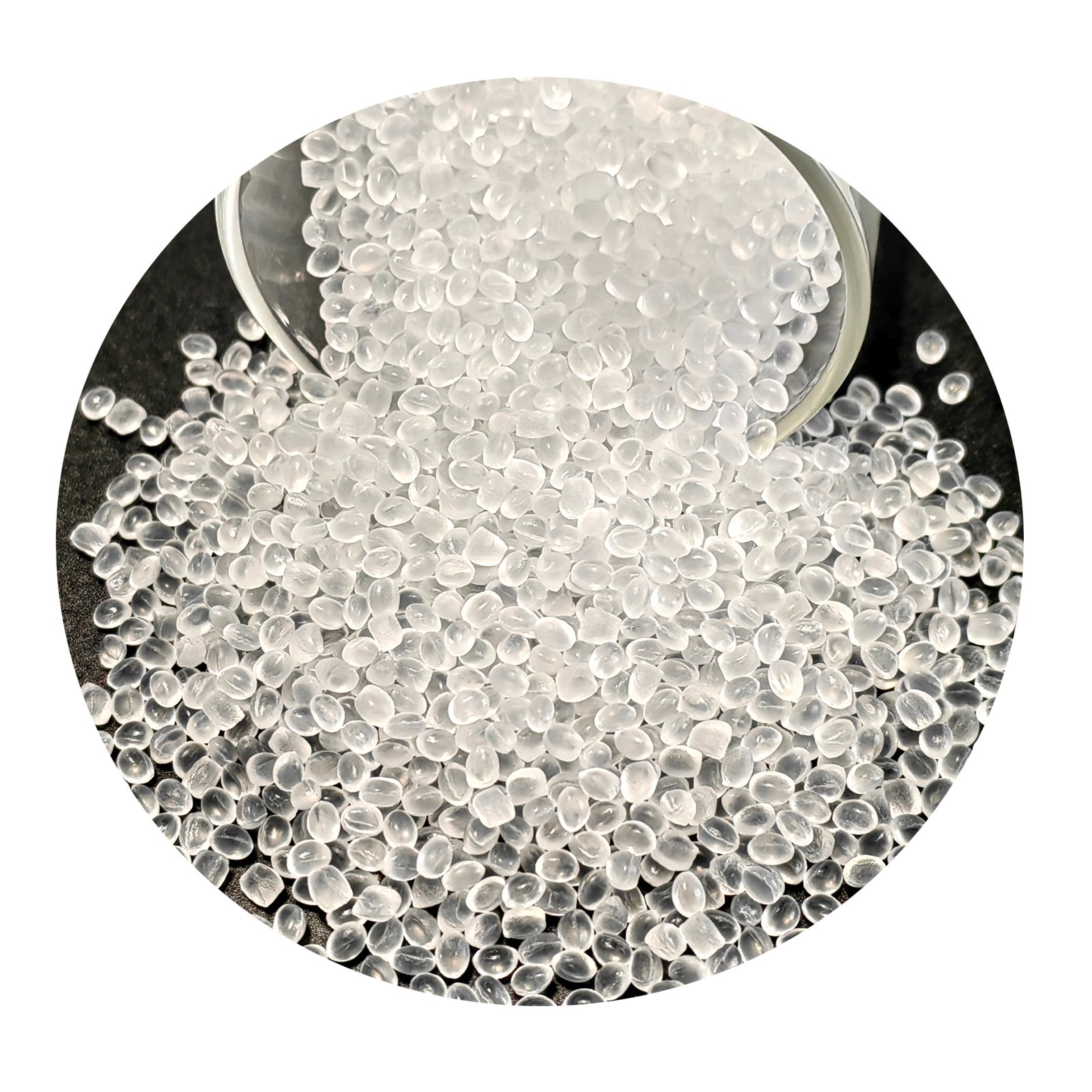

What is POE Resin

In soft plastics applications, balancing toughness, impact resistance and low-temperature performance is always a concern for engineers. POE 5061 from ExxonMobil, with its scientific ethylene-octene copolymerisation design and metallocene-catalyzed process, is providing new options for the film, shoe and modified plastics industries.

01 | Technical Background: Metallocene Catalysis Reinvents the Elastic Gene

Unlike traditional polyolefin elastomers, POE 5061 uses a metallocene catalyst to control the structural distribution of the chain segments, significantly improving the material's physical toughness and low-temperature resilience. This ethylene-1-octene copolymer structure provides ultra-flexibility and good impact absorption, which opens up more possibilities for product design in a variety of fields.

02 | Rediscovering Flexible Materials: Product Characteristics of POE 5061

POE 5061 belongs to the family of metallocene polyolefin elastomers (poe resins), and has the following outstanding characteristics:

High ductility: 800% elongation at break, which maintains the structural integrity in the face of bending, stretching, and deformation, making it suitable for repeated stressful environments.

Excellent toughness and tear strength: 37 KN/m tear strength and 10MPa tensile strength at break, giving products good durability and reliability.

Low-temperature adaptability: Even in winter or cold environment, the material still remains soft and not easy to be brittle.

Lightweight and environmentally friendly: the specific gravity of 0.868g/cm³ helps to reduce the weight of the products, which is in line with the current trend of green manufacturing.

03 | More than one application: POE 5061's multi-field applications

With balanced mechanical and thermal properties, POE 5061 is widely used in:

✔ Film and packaging industry: Blown film, cast film, can effectively improve the flexibility and low temperature resistance of the product, to extend the service life.

✔ Footwear manufacturing: for soles and soft parts, improve comfort and cushioning effect, especially suitable for sports shoes, casual shoes field.

✔ Plastic modification programme: as a toughening agent widely used in PP, TPO and other modification systems, to enhance the impact resistance and low temperature performance of plastics, used in automotive interior and exterior, home appliance parts, etc.

✔ Extrusion and injection moulding: to meet the demand for flexibility of soft profiles and profiles, suitable for building decoration, soft wrapping edges, tubes and other products.

04 | Quick overview of technical parameters: Performance advantages of POE 5061

| Mechanical behavior | Condition | Standard | Value | Unit | |||

| Elongation | Break | INTERNAL METHOD | 800 | % | |||

| Flexural Modulus | 1% Secant | INTERNAL METHOD | 13 | MPa | |||

| Tensile Strength | 23°C 100% Strain | INTERNAL METHOD | 2.5 | MPa | |||

| Tensile Strength | 23°C 300% Strain | INTERNAL METHOD | 3.50 | MPa | |||

| Tensile Strength | Break | INTERNAL METHOD | 10 | MPa | |||

| Tearing Strength | Die C | INTERNAL METHOD | 37.0 | KN/m | |||

| Thermal | Condition | Standard | Value | Unit | |||

| Melting Temperature | INTERNAL METHOD | 53 | °C | ||||

| Vicat Softening Temperature | INTERNAL METHOD | 55.5 | °C | ||||

| Physical property | Condition | Standard | Value | Unit | |||

| Density | ASTM D1505 | 0.868 | g/cm³ | ||||

| Melt Index | 190°C 2.16kg | ASTM D1238 | 0.50 | g/10min | |||

| Melt Index | 230°C 2.16kg | ASTM D1238 | 1.2 | g/10min | |||

| Mooney Viscosity | ML1+4 125°C | INTERNAL METHOD | 27 | MU | |||

| Hardness | Condition | Standard | Value | Unit | |||

| Shore Hardness A | INTERNAL METHOD | 70 | |||||

| Shore Hardness D | INTERNAL METHOD | 19 | |||||

05 | Why more and more companies choose POE 5061?

✔ From ExxonMobil, reliable technology, stable quality

✔ metallocene catalyst, chain segment structure can be controlled, balanced performance

✔ high softness, impact resistance, suitable for high-end product design

✔ low melt index, good processability, suitable for multi-process moulding

✔ Ideal material under the trend of lightweighting, help to reduce cost and increase efficiency

06 | Our advantage: not only material, but also service guarantee

As a long-term supply chain partner in the plastics industry, we have:

・24 years of experience in the industry, familiar with a variety of poe resin materials and application scenarios

・Free sample support to help you quickly verify the performance of the product

・One-to-one communication with the technical team, to help solve the processing problems

・Flexible sourcing solutions, to ensure the stability and reliability of the supply

・Looking for a trustworthy POE 5061 supply channel? Welcome to contact us for samples and detailed information to help your product solutions faster.

【Related Recommendations】

POE 8203: Flexible and Clear Polyolefin Elastomer for Extrusion and Blown Film Applications Learn more>

POE 2300: Food-Grade POE Plastic Resin with High Elasticity for Toughening Applications Learn more>

POE 0203: Versatile POE Plastic with Low-Temperature Sealing and High Clarity Learn more>