PRODUCTS

Dow POE 8003 Plastic Resin Features Applications and Data Sheet

Product Struction

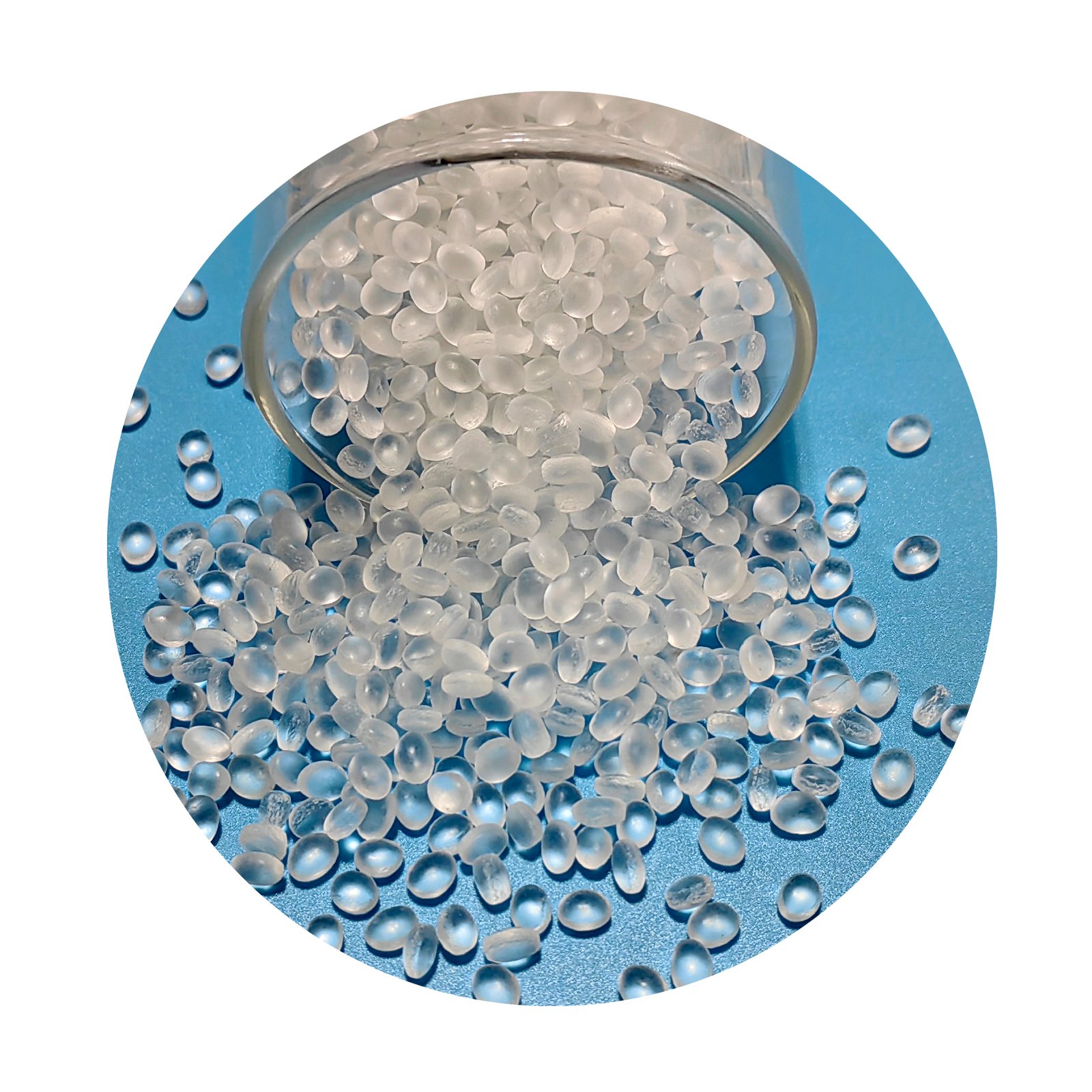

POE Plastic Resin Overview - Dow POE 8003

Today, with the increasing integration of flexible plastics and high-strength polymers, single-performance materials are no longer able to meet the complex demands of engineering plastics. With the advancement of automotive lightweighting, green packaging and multi-functionalization of composite materials, cross-linkable polyolefin elastomers (POE plastic resin) have witnessed a new peak of attention.

Dow POE 8003 is precisely a material solution tailored for high-end modification scenarios against this backdrop. It is not merely a "soft" existence, but also a philosophy of balance between toughness and structure, offering new possibilities for material engineers and product designers.

01 | POE Plastic Resin Logic: Deconstructing "Compatibility + Adaptability" from Molecular Design

Unlike the single copolymer structure of ordinary POE plastic resin, POE 8003 adopts an ethylene-butene + ethylene-octene composite platform, which not only brings a broader elastic range, but also enhances the compatibility of the material in various parent systems.

・High ductility: The elongation at break is as high as 640%, providing a "buffer layer" effect during structural deformation.

・Medium to high tensile strength: 18.2 MPa, suitable for supporting components;

・The tear strength reaches 61.0 KN/m, making it perform well in thin-walled products.

・The melting temperature is 77°C + crosslinking property, which is suitable for various composite heat treatment requirements such as cable foaming and shoe material lamination.

・Specific gravity 0.885 g/cm³, contributing to the lightweight goal of the product;

Its hardness (Shore A 84 / D 31) enables it to meet the modification challenges of combining rigidity and flexibility, such as PP reinforcement, TPO toughening, structural coating, etc.

02 | Application Insights: Not Just Modification, But an "Enabling Design Component"

Flexible skeleton for automotive lightweighting

In systems such as interior parts, bumpers, and TPO panels that require "light + strong + flexible", POE 8003 plastic resin provides a stress absorption path with low density and high toughness to enhance the vehicle's collision response performance.

Green packaging and high-flexibility film materials

In the design of environmentally friendly composite films that pursue recyclability, the high compatibility of POE 8003 with PE and PP and the advantage of low crystallization temperature make it an indispensable core material in the formulation of environmentally friendly films.

Foaming and elastic layer of shoe materials

With its cross-linking ability and good adhesion, POE 8003 provides excellent cushioning support in scenarios such as the elastic core layer of shoe soles and the sports cushion layer.

03 | Comparative Perspective: Why Choose POE 8003?

| Criteria | POE 8003 | Conventional POE |

| Tear Strength | 61.0 KN/m | 40–50 KN/m |

| Tensile Strength | 18.2 MPa | 6–10 MPa |

| Crosslinking Capability | ✅ Excellent | ⚠️ Limited |

| Recyclability | ✅ Compatible with PE/PP | ✅ |

| Thermal Processing Stability | Excellent | Moderate |

04 | Technical Performance Overview: The Structural Logic Behind the Numbers

| Mechanical behavior | Condition | Standard | Value | Unit | |||

| Elongation | Break 510mm/min Compression Molded | ASTM D638 | 640 | % | |||

| Flexural Modulus | ASTM D790 | 33.7 | MPa | ||||

| Flexural Modulus | ASTM D790 | 32.6 | MPa | ||||

| Tensile Strength | Break 510mm/min Compression Molded | ASTM D638 | 18.2 | MPa | |||

| Tensile Modulus | Compression Molded | ASTM D638 | 4.80 | MPa | |||

| Tearing Strength | Die C | ASTM D624 | 61.0 | KN/m | |||

| Thermal | Condition | Standard | Value | Unit | |||

| Melting Temperature | DSC 10℃/min | INTERNAL METHOD | 77.0 | ℃ | |||

| Glass Transition Temperature | INTERNAL METHOD | -46.0 | ℃ | ||||

| Crystallization Temperature | DSC | INTERNAL METHOD | 60.0 | ℃ | |||

| Vicat Softening Temperature | ASTM D1525 | 63.0 | ℃ | ||||

| Physical property | Condition | Standard | Value | Unit | |||

| Density | ASTM D792 | 0.885 | g/cm³ | ||||

| Melt Index | 190℃ 2.16kg | ASTM D1238 | 1.0 | g/10min | |||

| Mooney Viscosity | ML1+4 121℃ | ASTM D1646 | 22 | MU | |||

| Hardness | Condition | Standard | Value | Unit | |||

| Shore Hardness A | Compression Molded | ASTM D2240 | 84 | ||||

| Shore Hardness D | Compression Molded | ASTM D2240 | 31 | ||||

05 | Scene micro-cases · The ability to solve real problems

A Southeast Asian automotive interior parts supplier encountered difficulties when introducing a recyclable TPO modification solution: the material was too brittle to pass the low-temperature impact test. By our suggestion of adding 5% POE 8003, the flexibility of the product has been significantly improved, and the test pass rate has increased from 42% to 95%. The customer finally locked in POE 8003 as the long-term cooperative material source.

06 | It has both excellent low-temperature adaptability and environmental protection characteristics

The glass transition temperature of POE 8003 plastic resin is only -46°C, ensuring that it can maintain a flexible form even in extremely cold environments. It is suitable for export to severely cold regions such as North America, Northern Europe and Central Asia. In addition, it complies with food contact grade standards and has been extended to packaging applications with high safety requirements.

Due to its polyolefin nature, POE 8003 can be recycled and processed together with PE/PP, has a high compatibility in the green circular system, and is in line with the policy orientation of sustainable development.

07 | Why choose the POE 8003 we offer?

We not only sell "materials", but also deliver a systematic solution:

✅ 24 years of experience in plastic modification and industry formulations

✅ Free POE 8003 plastic resin sample, fast delivery, technical guidance

✅ offers on-demand formulation adjustment suggestions and supports blend designs with high and low hardness

✅ can help from sample production to small batch and then to stable large supply

✅ If required, we can assist in preparing application formulation proposal and processing window parameters

Would you like to try what problems the resilience of POE 8003 can solve for you?

Welcome to contact us to obtain samples and complete technical data. We are willing to be your long-term partner on the road of flexible material innovation.

【Related Recommendations】

POE C11075DF: Lightweight Metallocene Polyolefin for Automotive and Foaming Applications Learn more>

POE 7467: Lightweight Polyolefin Elastomer for Toughening and Flexible Packaging Learn more>

POE 5371: Soft and Tough Polyolefin Elastomer for Film, Foam, and Injection Applications Learn more>